CNT Reinforced Composites – How They Improve Strength and Toughness

In recent years, carbon nanotube (CNT) reinforced composites have become one of the most exciting innovations in materials science.

Known for their exceptional strength, flexibility, and conductivity, CNTs have been widely studied as reinforcement additives for polymers, metals, and ceramics. When properly dispersed, they can dramatically improve tensile strength, fracture toughness, and fatigue life — even at very low loading levels.

This article explains how CNTs enhance composite performance, the key processing methods, and their industrial applications in sectors such as aerospace, automotive, construction, and consumer products.

1. Why Use CNTs in Composite Materials?

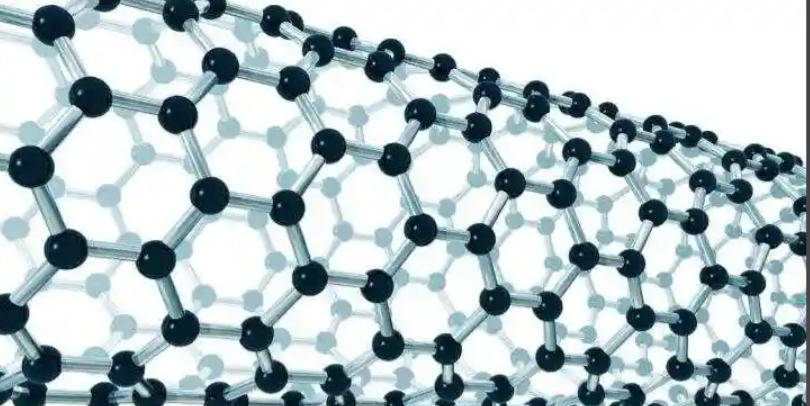

Carbon nanotubes are cylindrical carbon structures composed of rolled graphene sheets.

They can be single-walled (SWCNTs) or multi-walled (MWCNTs), with diameters ranging from 1–50 nm and aspect ratios exceeding 10,000:1.

These unique characteristics give CNTs:

-

Tensile strength up to 100 GPa

-

Young’s modulus around 1 TPa

-

Thermal conductivity above 3,000 W/m·K

-

Electrical conductivity up to 10⁶ S/m

-

Density lower than aluminum (~1.4 g/cm³)

Such a combination of strength, lightness, and conductivity makes CNTs ideal for use as nanoscale reinforcement agents in advanced composite materials.

2. How CNTs Improve Strength and Toughness

CNTs act as microscopic reinforcements that bridge defects, distribute stress, and resist crack propagation within the matrix material.

Several strengthening mechanisms work together:

2.1 Load Transfer

CNTs carry part of the mechanical load applied to the composite. Strong interfacial bonding between the CNT and matrix allows efficient stress transfer.

2.2 Crack Bridging and Deflection

When cracks form, CNTs bridge across them and absorb fracture energy, slowing or preventing further propagation.

This significantly increases fracture toughness and fatigue resistance.

2.3 Pull-Out and Sliding

CNTs may slide or pull out during failure, dissipating mechanical energy and increasing impact strength.

2.4 Grain Refinement and Matrix Interaction

In metal or ceramic composites, CNTs act as nucleation sites, refining grain structure and improving mechanical homogeneity.

2.5 Network Formation

At higher loadings, CNTs form interconnected networks that improve stress distribution and energy absorption throughout the composite.

Even small CNT additions (0.1–2 wt%) can yield 20–80% mechanical improvements, depending on the dispersion quality and bonding strength.

3. Types of CNT Reinforced Composites

3.1 Polymer Matrix Composites (PMCs)

CNTs are commonly used to reinforce epoxy, polyurethane, polyimide, nylon, and thermoplastics.

Benefits:

-

Tensile strength increase by 30–50%

-

Better fracture toughness and wear resistance

-

Enhanced electrical and thermal conductivity

-

Lightweight, flexible performance

Applications: Aerospace panels, automotive interiors, sports goods, wearable devices.

3.2 Metal Matrix Composites (MMCs)

CNTs embedded in aluminum, copper, magnesium, or titanium improve both strength and conductivity.

Benefits:

-

Higher hardness and fatigue life

-

Reduced wear and corrosion

-

Improved heat dissipation

Applications: Heat sinks, structural frames, lightweight machine parts, high-end electronics.

3.3 Ceramic Matrix Composites (CMCs)

CNTs reinforce alumina (Al₂O₃), silicon carbide (SiC), or zirconia (ZrO₂) ceramics.

Benefits:

-

Enhanced fracture toughness (up to 2× increase)

-

Crack deflection and bridging

-

Improved thermal shock resistance

Applications: Cutting tools, high-temperature coatings, armor materials.

4. Processing Methods

Achieving uniform CNT dispersion is critical for consistent reinforcement. Several fabrication techniques are used depending on the matrix material.

4.1 Solution Blending (for Polymers)

-

CNTs dispersed in solvent with polymer resin using ultrasonication or shear mixing.

-

Good for low-viscosity resins such as epoxy.

-

Common in laboratory-scale composite preparation.

4.2 Melt Compounding

-

CNTs mixed into molten thermoplastics using an extruder.

-

Industrially scalable and compatible with injection molding.

-

Requires optimized screw design to prevent CNT damage.

4.3 In-Situ Polymerization

-

CNTs introduced during polymer synthesis.

-

Provides excellent CNT-matrix bonding and uniform dispersion.

4.4 Powder Metallurgy (for Metals)

-

CNTs mixed with metal powders, then hot-pressed or spark plasma sintered.

-

Produces dense, conductive metal-CNT composites.

4.5 Sol-Gel or Sintering (for Ceramics)

-

CNTs are mixed with ceramic precursors and sintered at high temperature.

-

Special care is needed to prevent CNT oxidation.

5. Mechanical Performance Improvements

| Property | Improvement Range | Key Mechanism |

|---|---|---|

| Tensile Strength | +20–60% | Load transfer through CNT network |

| Elastic Modulus | +10–40% | Enhanced stiffness from high CNT modulus |

| Fracture Toughness | +30–100% | Crack bridging, pull-out mechanisms |

| Fatigue Life | +50–200% | Energy dissipation and stress redistribution |

| Wear Resistance | +20–70% | Surface hardening and micro-reinforcement |

These improvements depend on CNT alignment, aspect ratio, and dispersion quality — all controllable through optimized processing.

6. Interfacial Bonding and Functionalization

Strong interfacial bonding is essential for efficient stress transfer. However, pristine CNTs are chemically inert, making adhesion challenging.

To improve bonding, surface functionalization is used:

6.1 Covalent Functionalization

-

Introduces chemical groups (-COOH, -OH, -NH₂) to CNT surfaces.

-

Improves adhesion with polymer or metal matrices.

-

May slightly reduce electrical conductivity.

6.2 Non-Covalent Functionalization

-

Uses surfactants or polymer wrapping to improve dispersion without damaging CNT structure.

-

Maintains electrical properties but may have weaker bonding.

6.3 Hybrid Fillers

-

Combining CNTs with graphene, carbon black, or nanoclay enhances both dispersion and mechanical performance.

7. Real-World Applications

7.1 Aerospace and Automotive

-

CNT composites reduce component weight while maintaining mechanical strength.

-

Used in body panels, brackets, and structural components.

-

Improved vibration damping and fatigue resistance.

7.2 Sporting Goods

-

High-end bicycles, tennis rackets, and helmets use CNT composites for stiffness and impact strength.

7.3 Construction and Infrastructure

-

CNT-reinforced polymers and concrete exhibit improved crack resistance and load-bearing capacity.

7.4 Electronics and Energy

-

CNT composites enhance heat dissipation in housings and improve mechanical reliability in flexible circuits.

7.5 Industrial Coatings

-

CNTs in coatings improve abrasion resistance, conductivity, and thermal performance for pipelines and mechanical parts.

8. Challenges and Solutions

8.1 CNT Dispersion

-

CNTs tend to agglomerate due to van der Waals forces.

-

Solution: Use of surfactants, ultrasonication, or chemical functionalization.

8.2 Alignment Control

-

Random CNT orientation limits mechanical enhancement.

-

Solution: Use shear flow, magnetic/electric fields, or extrusion-induced alignment.

8.3 Cost and Scale

-

High-quality CNTs remain expensive, though industrial production costs are decreasing as CVD and catalytic synthesis scale up.

8.4 Interfacial Compatibility

-

Poor bonding leads to weak reinforcement.

-

Solution: Functionalization and coupling agents to enhance adhesion.

9. Hybrid and Next-Generation CNT Composites

Research is moving toward multi-functional hybrid composites that combine strength with other properties.

-

CNT + Graphene: Enhances both tensile and electrical performance.

-

CNT + Ceramic Nanoparticles: Improves hardness and thermal stability.

-

CNT + Natural Fibers: For sustainable, bio-based composites.

-

CNT 3D Networks: Creating percolated, lightweight conductive structures.

These materials are opening doors to smart composites capable of self-sensing, energy storage, or electromagnetic shielding.

10. Future Trends

10.1 3D Printing of CNT Composites

Additive manufacturing with CNT-filled polymers enables complex lightweight designs with built-in conductivity and structural integrity.

10.2 Structural Health Monitoring

CNT networks act as built-in strain or damage sensors, allowing real-time monitoring of structural integrity.

10.3 Thermal Management Applications

With their high thermal conductivity, CNT composites are ideal for battery housings, EV cooling plates, and electronics enclosures.

10.4 Sustainable Production

Green synthesis routes and recyclable CNT-reinforced thermoplastics are gaining attention for eco-friendly industrial production.

CNT reinforced composites represent a key step toward the next generation of lightweight, high-strength, and multifunctional materials.

Through effective dispersion, strong interfacial bonding, and optimized processing, CNTs can significantly enhance both strength and toughness, while adding electrical and thermal functionalities.

Their use in aerospace, automotive, construction, and electronics is expanding rapidly as industries seek stronger, lighter, and smarter materials.

As CNT production becomes more scalable and cost-effective, we can expect widespread adoption across structural, functional, and flexible product designs — marking a major transformation in advanced material technology.