Graphene-Enhanced Concrete – Strength, Durability, and Smart Structures

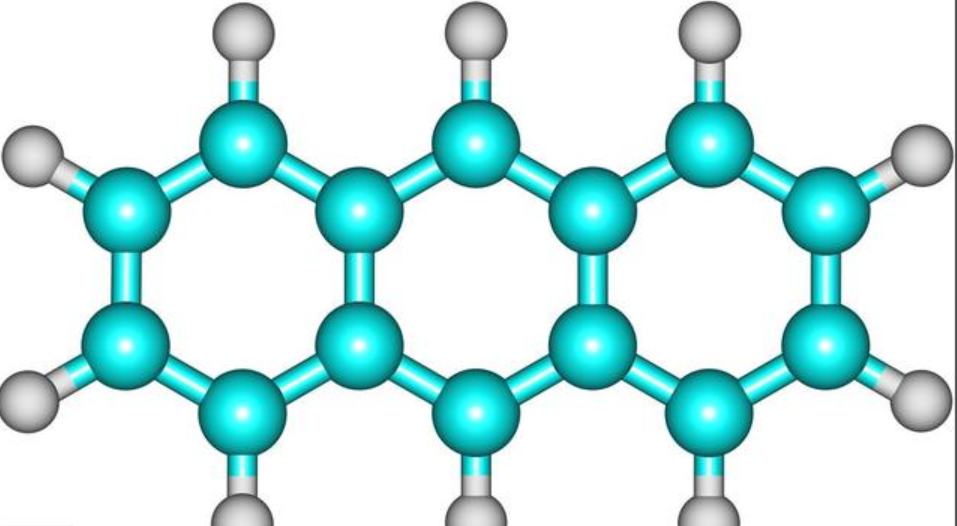

Concrete is one of the most widely used construction materials in the world — from buildings and bridges to roads and tunnels. However, traditional concrete has well-known limitations: it’s heavy, prone to cracking, and susceptible to environmental degradation. To meet the growing demand for sustainable, longer-lasting infrastructure, researchers and engineers have begun integrating graphene into cement and concrete formulations.

Graphene-enhanced concrete represents a new class of advanced construction materials that combine mechanical strength, durability, and even smart sensing capabilities. By adding a very small amount of graphene or graphene derivatives, concrete can become stronger, denser, and more resistant to water and chemical attack — while also enabling functionalities like self-sensing and thermal management.

This article explores how graphene improves concrete at the microstructural level, key performance benefits, and its future role in smart infrastructure.

1. Why Add Graphene to Concrete?

Concrete’s strength and durability depend heavily on its microstructure, especially the cement hydration process and the resulting porosity. Traditional concrete contains microscopic voids and cracks that gradually expand under stress or environmental exposure. This allows water, salts, and gases to penetrate — leading to corrosion, cracking, and eventual failure.

Graphene, due to its unique 2D nanostructure and atomic-scale properties, offers several improvements:

-

High mechanical strength (Young’s modulus ≈ 1 TPa)

-

Excellent electrical and thermal conductivity

-

Large surface area (~2600 m²/g)

-

Chemical stability and impermeability

When properly dispersed, graphene acts as a nano-reinforcement and a microstructural enhancer, bridging micro-cracks and refining the cement matrix.

2. How Graphene Works Inside Concrete

The performance improvements come from both physical and chemical effects of graphene within the cementitious matrix.

2.1 Nucleation and Hydration Enhancement

Graphene and graphene oxide (GO) provide nucleation sites during cement hydration.

This means cement particles hydrate more efficiently, forming a denser and more uniform microstructure. The result is:

-

Reduced micro-pores,

-

Improved bonding between cement phases,

-

And higher compressive and tensile strength.

2.2 Crack Bridging and Load Transfer

Graphene sheets act as nano-bridges across microcracks, distributing stress more evenly.

This helps delay crack propagation and enhances the toughness and flexural strength of the material.

2.3 Barrier to Water and Chemicals

Graphene’s atomic structure makes it nearly impermeable to gases and liquids.

When integrated into the cement matrix, it significantly reduces water absorption and chloride ion penetration, improving long-term durability — especially for coastal or industrial environments.

2.4 Functional Conductivity

Unlike traditional concrete (which is insulating), graphene-enhanced concrete becomes electrically conductive.

This opens the door to smart infrastructure applications such as:

-

Self-sensing strain or crack detection,

-

De-icing systems via Joule heating,

-

Electromagnetic shielding in tunnels or power facilities.

3. Key Performance Improvements

Even at very low loading levels (typically 0.05–0.5 wt%), graphene can significantly improve the performance of concrete.

Below is a summary of commonly reported enhancements from laboratory and pilot-scale studies.

| Property | Typical Improvement with Graphene |

|---|---|

| Compressive Strength | +20% to +50% |

| Flexural Strength | +30% to +60% |

| Water Permeability | −50% to −80% |

| Chloride Ion Penetration | −40% to −70% |

| Crack Resistance | Greatly improved |

| Durability / Service Life | Extended by 2–3× |

| Electrical Conductivity | 10⁴–10⁶× increase |

These gains make graphene concrete particularly attractive for infrastructure, marine structures, and high-performance building materials.

4. Types of Graphene Used in Cement and Concrete

The choice of graphene material has a major impact on dispersion, performance, and cost.

4.1 Graphene Oxide (GO)

GO is one of the most commonly used additives because it disperses easily in water and forms strong chemical bonds with cement hydrates through its oxygen-containing groups.

-

Enhances hydration and bonding.

-

Improves mechanical and barrier properties.

-

Ideal for strength and durability enhancement.

4.2 Reduced Graphene Oxide (rGO)

rGO has fewer oxygen groups, offering better electrical conductivity.

-

Used for smart or conductive concrete applications (e.g., de-icing, sensing).

-

Requires surface treatment to ensure dispersion.

4.3 Pristine Graphene / Graphene Nanoplatelets

Used where high thermal and electrical conductivity is required.

However, dispersion can be challenging; surfactants or mechanical mixing are often needed.

5. Dispersion and Processing Considerations

The biggest technical challenge in using graphene for concrete is achieving uniform dispersion.

Because graphene tends to agglomerate, poor mixing can lead to uneven performance and wasted material.

Common dispersion methods include:

-

Ultrasonic mixing or high-shear blending.

-

Using surfactants or polymer dispersants.

-

Pre-formulating graphene slurries or masterbatches for cement mixing.

Properly dispersed graphene ensures consistent hydration reaction, mechanical reinforcement, and electrical connectivity throughout the matrix.

6. Smart and Functional Concrete Applications

Graphene-enhanced concrete isn’t just stronger — it’s also smarter. The integration of conductive graphene networks allows for multifunctional capabilities.

6.1 Self-Sensing Structures

By measuring changes in electrical resistance, graphene concrete can detect:

-

Stress and strain,

-

Crack initiation,

-

Structural fatigue.

This property allows real-time monitoring of bridges, tunnels, or buildings — enhancing safety and maintenance efficiency.

6.2 Self-Heating and De-Icing Pavements

When voltage is applied, conductive graphene networks can generate heat via Joule heating, enabling:

-

Snow and ice removal from roads or runways.

-

Temperature control in industrial flooring.

Compared with embedded heating cables, graphene-based systems are uniform, thin, and energy-efficient.

6.3 Electromagnetic Interference (EMI) Shielding

Graphene’s electrical conductivity provides natural EM shielding — valuable in data centers, medical buildings, and smart cities where EMI control is crucial.

6.4 Energy Storage and Thermal Regulation

Recent studies explore using graphene concrete as part of thermal energy storage systems or even as electrochemical capacitive layers, hinting at the future of energy-integrated infrastructure.

7. Environmental and Sustainability Benefits

Beyond performance, graphene-enhanced concrete contributes to sustainability in several ways:

-

Reduced cement consumption: Higher strength allows using less cement per cubic meter.

-

Longer lifespan: Less maintenance and lower CO₂ emissions over the life cycle.

-

Lower permeability: Reduced corrosion means less steel reinforcement degradation.

-

Potential CO₂ reduction: Some formulations incorporate CO₂ curing for added environmental benefit.

With construction contributing nearly 8% of global CO₂ emissions, even small performance improvements can translate into major environmental savings.

8. Challenges and Future Outlook

While results are promising, several technical and commercial challenges remain:

-

Cost and scalability: Graphene production costs are decreasing, but mass application in ready-mix concrete still requires optimization.

-

Dispersion reproducibility: Consistent quality control is key to reliable field performance.

-

Standardization: Industry standards for graphene content, testing, and certification are still under development.

-

Long-term validation: More real-world field data is needed for certification and large-scale adoption.

Despite these hurdles, many pilot projects — from UK-based “Concretene” trials to Asia’s smart building programs — have demonstrated the practical potential of graphene concrete.

As production and formulation technologies mature, graphene-enhanced concrete is poised to become part of mainstream infrastructure development.

Graphene-enhanced concrete represents a major leap forward for the construction industry. By improving mechanical strength, durability, and functional performance, it addresses some of the most critical limitations of traditional materials.

Key advantages include:

-

20–50% higher compressive strength.

-

2–3× longer service life.

-

Improved impermeability and corrosion resistance.

-

Potential for smart sensing and self-heating.

For engineers, architects, and infrastructure developers, graphene concrete provides a pathway toward stronger, smarter, and more sustainable construction — a foundation for the next generation of resilient cities and energy-efficient buildings.