CNTs in 3D Printing Filaments – Conductivity and Mechanical Strength

How carbon nanotubes enhance FDM/FFF filaments for engineering applications

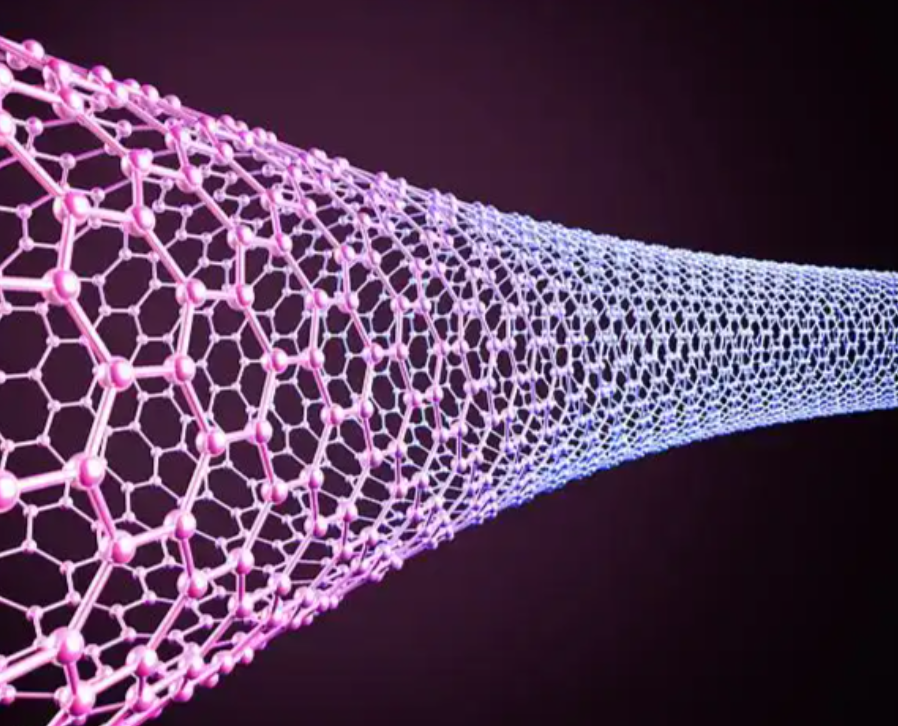

3D printing is moving rapidly from prototyping to functional, end-use parts. As this shift accelerates, engineers are seeking materials that offer higher strength, better durability, and added functionalities such as electrical or thermal conductivity. Carbon nanotubes (CNTs) have emerged as one of the most effective additives for upgrading polymer filaments, especially in FDM/FFF 3D printing.

CNT-reinforced 3D printing filaments combine the versatility of polymers with the advanced mechanical, electrical, and thermal properties of nanoscale carbon structures. This article explains how CNTs improve filament performance, which polymers benefit most, and what customers should consider when selecting CNT-filled materials for industrial applications.

1. Why Use CNTs in 3D Printing Filaments?

Carbon nanotubes bring a unique combination of advantages to polymer filaments:

1.1 Mechanical Strength & Toughness

CNTs have extremely high tensile strength (up to 100 GPa).

When well-dispersed, they significantly improve:

-

tensile strength

-

layer adhesion

-

impact resistance

-

wear resistance

Even 0.1–2% CNT loading can lead to measurable improvements.

1.2 Electrical Conductivity

CNT networks form conductive pathways inside the polymer.

This allows applications such as:

-

ESD-safe parts

-

antistatic components

-

low-voltage circuits

-

sensor housings

-

electromagnetic shielding

Typical resistivity range for CNT filaments:

10²–10⁶ Ω·cm, depending on loading and polymer type.

1.3 Thermal Conductivity Enhancement

CNTs improve heat dissipation in printed parts—useful for:

-

LED housings

-

battery fixtures

-

fixtures exposed to heat

-

molds and jigs under temperature stress

1.4 Dimensional Stability & Less Warping

CNTs help:

-

reduce shrinkage

-

stabilize layer deposition

-

improve the crystallization behavior of semi-crystalline polymers

This leads to smoother printing and fewer failure rates.

2. CNT Grades Used in 3D Printing

CNTs for filaments typically fall into three categories:

2.1 Multi-Wall Carbon Nanotubes (MWCNTs)

Most common for filaments:

-

cost-effective

-

good balance of electrical + mechanical enhancement

-

easier to disperse in polymers

-

stable during melt compounding

Best for: PLA, ABS, PETG, TPU, PA, PC.

2.2 Single-Wall CNTs (SWCNTs)

Higher performance but more expensive.

Used where very high conductivity is needed at low loading.

2.3 Functionalized CNTs

Surface-modified CNTs (COOH, OH, NH₂) offer:

-

improved compatibility with polar polymers

-

better dispersion

-

stronger interface bonding

Useful for PA, PET, PC, epoxy-based composite filaments.

3. How CNTs Improve Filament Properties

CNTs work through three main mechanisms:

3.1 Reinforcement of the Polymer Matrix

CNTs act as nanoscale “fibers,” distributing stress and increasing the toughness of printed parts.

3.2 Formation of Conductive Networks

Once CNTs reach the percolation threshold (typically 0.1–1 wt%), they form continuous paths for electron flow.

3.3 Modification of Crystallization Behavior

CNTs act as nucleating agents, helping polymers crystallize in a more controlled manner, which reduces warping.

4. CNT-Enhanced Filaments by Polymer Type

Below are the most common polymers upgraded with CNTs.

4.1 PLA + CNT

-

Easy to print

-

Better impact strength

-

ESD-safe versions available

Good for prototyping functional parts with basic conductivity.

Applications:

-

drone shells

-

functional brackets

-

educational robotics

4.2 ABS + CNT

CNTs greatly improve ABS toughness and conductivity.

Benefits:

-

enhanced layer bonding

-

reduced warping

-

good for industrial fixtures

Applications:

-

jigs & fixtures

-

low-voltage printed circuits

-

housings requiring ESD protection

4.3 PETG + CNT

PETG prints easily and remains strong; CNTs add conductivity and strength.

Used for:

-

transparent or semi-transparent conductive parts

-

sensor housings

-

chemical-resistant fixtures

4.4 Nylon (PA6/PA12) + CNT

Among the best combinations for real engineering performance.

Advantages:

-

very high mechanical strength

-

good toughness

-

stable electrical properties

Ideal for industrial-grade parts.

4.5 TPU + CNT (Flexible Conductive Filaments)

CNTs add conductivity while preserving elasticity.

Applications:

-

wearable sensors

-

flexible circuits

-

stretchable electrodes

5. Key Performance Parameters for Customers

When selecting CNT filaments, engineers focus on:

5.1 Volume Resistivity

Defines electrical performance.

Typical ranges:

-

ESD-safe: 10⁵–10⁹ Ω

-

Antistatic: 10⁹–10¹¹ Ω

-

Conductive: 10²–10⁵ Ω

5.2 CNT Loading Level

Higher loading = more conductivity but more challenging printing.

Optimized formulations usually use 0.2–4 wt%.

5.3 Dispersion Quality

The most crucial factor:

Better dispersion = better mechanical and electrical properties.

5.4 Filament Diameter Stability

CNTs can affect melt flow, so high-quality extrusion is important.

5.5 Nozzle Wear

CNTs are abrasive—hardened nozzles are recommended.

6. Industrial Applications Enabled by CNT Filaments

CNT-filled 3D printing materials unlock practical applications beyond prototyping:

6.1 ESD-Safe Components

For electronics manufacturing, storage, and handling.

6.2 Printed Sensors & Conductive Traces

CNT filaments allow simple printed circuits, switches, and resistors.

6.3 Structural Parts

Nylon/CNT parts are strong enough for:

-

robot components

-

mechanical brackets

-

tooling fixtures

6.4 Automotive & EV Components

CNT-filled filaments contribute to lightweight functional parts.

6.5 Aerospace & UAV

Ideal for strong, lightweight, custom components with integrated conductivity.

7. What We Offer

We supply CNT materials and dispersions tailored for filament manufacturers:

• Industrial-grade MWCNT

• High-purity MWCNT

• Functionalized CNT (COOH, OH, NH₂)

• CNT masterbatches for polymer compounding

• CNT dispersions (water/solvent/oil-based)

Support includes blending guidance, dispersion methods, and pilot-scale testing.

CNT-reinforced 3D printing filaments provide a powerful way to upgrade common polymers with strength, conductivity, and improved printing performance, enabling functional end-use components across multiple industries.

As 3D printing expands into manufacturing-grade applications, CNT filaments will continue to play a central role in enabling smarter, stronger, and more advanced printed parts.