Wearable Smart Heating Textiles Powered by Graphene Films

How ultrathin carbon heaters are redefining mobile warmth, performance apparel, and medical garments

Wearable heating technology is no longer limited to bulky wires or battery-driven pads. The rapid rise of graphene heating films—flexible, transparent, lightweight, and highly efficient—has opened the door to a new generation of smart heating textiles used in outdoor gear, sports apparel, medical therapy, and even fashion design.

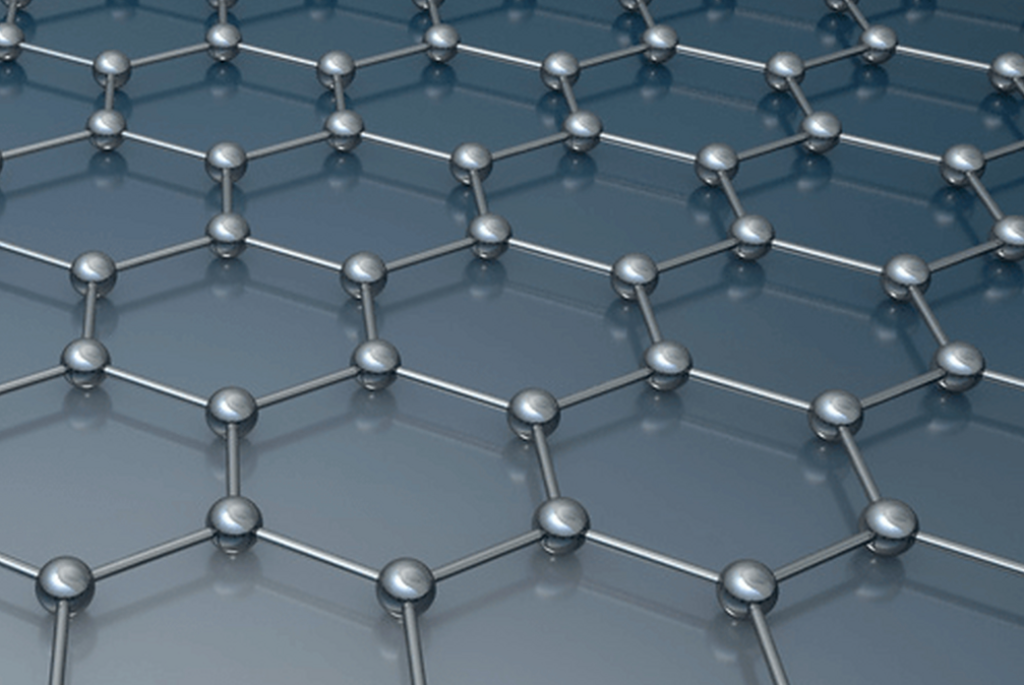

Graphene’s combination of high electrical conductivity, exceptional thermal uniformity, mechanical flexibility, and near-zero thickness makes it an ideal candidate for integrating heating capability directly into fabrics—without adding weight or compromising comfort.

This article explores how graphene films work in wearable heating textiles, design considerations, performance benchmarks, and the key challenges for mass adoption.

1. Why Graphene Heating Films Are Ideal for Wearable Textiles

Graphene films outperform conventional metal wires and printed heaters in four critical areas:

1.1 Ultra-Thin and Flexible

-

Film thickness from 5–50 μm, depending on type

-

Can bend, twist, fold, and stretch without cracking

-

Maintains stable resistance under deformation

This enables seamless integration into clothing layers or lamination onto fabric.

1.2 Extremely Uniform Heating

Graphene exhibits rapid in-plane heat conduction, eliminating hot spots common with wires.

Users experience smooth, even warmth across the panel.

1.3 Low Power Consumption

Graphene’s high conductivity means garments can reach:

-

40–45°C at only 3–5 W

-

55–60°C at 7–10 W

This extends battery life—critical for mobile wearables.

1.4 Lightweight and Breathable

Graphene films weigh only a few grams and can be perforated or patterned to maintain fabric breathability.

2. Types of Graphene Heating Films for Wearables

2.1 CVD Graphene Films

-

Ultra-thin, transparent

-

Highest conductivity

-

Used in advanced medical or luxury apparel

-

Expensive, limited scale

2.2 Graphene Nanoplatelet-Coated Films

-

Most widely used commercially

-

PET, PI, or TPU substrate + coated graphene ink

-

Good performance and scalable production

-

Ideal for jackets, gloves, socks, masks, etc.

2.3 Printed Graphene Ink Heaters

-

Screen printing or slot-die coating

-

Low-cost, mass-production friendly

-

Compatible with direct fabric printing or transfer

These products typically operate in the 8–30 V range depending on size and resistance.

3. Integration Methods: How Graphene Films Enter Fabric Systems

3.1 Lamination Between Textile Layers

-

Graphene film is sandwiched between fabric and lining

-

Uses heat-press TPU or PU film

-

Protected from mechanical damage and sweat

This is the most common solution for jackets and vests.

3.2 Direct Bonding to Fabric

-

Graphene printed or laminated directly onto fabric backing

-

Can follow garment shape or create custom heat zones

Suitable for sportswear where thinness and flexibility are essential.

3.3 Embedding in Elastic or Stretch Fabrics

-

Used for knee sleeves, back support belts, therapy pads

-

Heating film remains functional under stretching

Requires films with high strain tolerance.

4. Performance Metrics for Wearable Heating Textiles

4.1 Sheet Resistance (Ω/sq)

Typical graphene wearable heaters:

-

10–50 Ω/sq for 3.7–12V systems

-

50–200 Ω/sq for USB (5V) applications

Lower resistance = higher power output for a given voltage.

4.2 Heating Speed

Graphene heaters reach 40°C within 5–10 seconds, thanks to fast electron mobility and thin-film thermal diffusion.

4.3 Temperature Uniformity

Superior to wire-based systems:

-

Variation < ±3°C across surface

-

No hotspots → better comfort and safety

4.4 Durability

-

10,000+ bending cycles

-

Machine-washable after lamination

-

Stable under humid and cold environments

4.5 Power Consumption

Typical graphene textile heating zone (10×10 cm):

-

5V USB: 2–4 W

-

7.4V battery: 4–7 W

-

12V system: 8–12 W

5. Applications Across Industries

5.1 Outdoor and Sportswear

-

Heated jackets, gloves, vests, pants

-

For skiing, cycling, hiking

-

Lightweight warmth without bulky insulation

5.2 Medical and Therapeutic Wearables

Graphene’s FIR (far-infrared) emission enhances:

-

Blood circulation

-

Muscle relaxation

-

Pain relief (lower back, joints)

Graphene heaters allow precise temperature control for therapy garments.

5.3 Smart Fashion & Everyday Apparel

-

Heated scarves, shawls, hoodies

-

Transparent graphene films enable aesthetic designs

-

USB-powered clothes are emerging in consumer markets

5.4 Military and Industrial Clothing

-

Cold-environment survival suits

-

Breathable warm layers without sacrificing mobility

-

Low power draw suits battery-based systems

6. Key Technical Challenges

6.1 Long-term Washing Durability

Lamination and encapsulation must protect graphene from:

-

Water penetration

-

Detergents

-

Mechanical abrasion

TPU or PU laminated structures improve lifespan.

6.2 Resistance Stability Under Stretch

For flexible garments, strain-induced resistance change must be minimized.

CNT/graphene hybrids may provide better stretchability.

6.3 Battery Integration

Designers must consider:

-

Safe low-voltage operation

-

Weight distribution of battery packs

-

Efficient power management circuits

6.4 Standardization & Certification

Smart textiles must comply with:

-

IEC 60335 (safety of electric heating appliances)

-

ISO 20685 (wearable ergonomics)

-

Washability test standards (ISO 6330)

This is becoming increasingly important for exports.

7. Future Trends: Where Graphene Wearable Heating Is Going

7.1 Breathable, transparent graphene films

Advanced CVD-based heaters for ultralight apparel.

7.2 Stretchable graphene/CNT hybrid networks

Enabling fully flexible and washable heating lines.

7.3 Integrated smart control systems

-

Bluetooth temperature control

-

Thermistor-based heating algorithms

-

Power optimization for longer battery life

7.4 Multi-functional graphene textiles

Combined heating + sensing + energy storage:

-

Heated garments that monitor breathing or heart rate

-

Self-powered heated gloves (triboelectric or PV-assisted)

Graphene-powered heating textiles represent a major leap forward in comfort, efficiency, and design flexibility. Compared with traditional metal wires, graphene provides:

-

Better thermal uniformity

-

Much lower profile and weight

-

Higher durability

-

Lower power consumption

-

Greater comfort and design freedom

As manufacturing costs continue to decrease and integration technologies advance, graphene heating films are expected to become the mainstream solution for next-generation smart apparel, medical wearables, and high-performance textiles.