Production Capacity and Custom Services for Graphene Heating Film Solutions

Flexible Heating Technology for Smart Homes, EVs, Appliances, and Industrial Applications

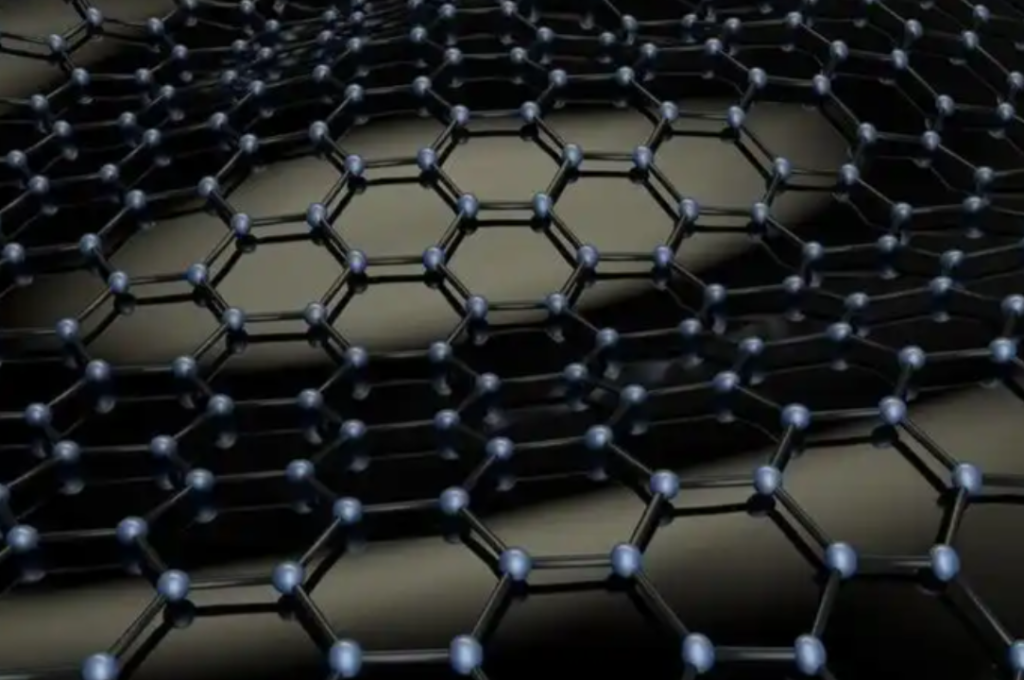

Graphene heating films are rapidly replacing traditional electric heating wires and carbon fiber heaters in multiple industries. With ultra-thin thickness, fast response speed, uniform heat distribution, and low energy consumption, graphene heating films are ideal for floor heating, automotive defogging, wearable heating, medical devices, battery thermal management, and consumer electronics.

For overseas distributors, integrators, and product manufacturers, two key purchasing questions always arise:

-

Can the supplier provide stable production capacity?

-

Do they support customization for different applications?

In this article, we introduce how our manufacturing capability, engineering support, and flexible customization services help small-to-medium OEM/ODM clients build competitive heating solutions with graphene film technology.

Why Graphene Heating Film? — Key Market Advantages

| Feature | Benefit for End Product |

|---|---|

| Ultra-thin (10–30 μm) | Comfortable floor heating / compact consumer devices |

| Uniform sheet resistance | Smooth, safe heat distribution without hot spots |

| Fast heating | Seconds-level warm-up for EV and smart wearables |

| Low voltage compatible | Suitable for batteries and portable electronics |

| Flexible and durable | Ideal for curved surfaces and textiles |

| Printable and scalable | High automation, low tooling cost |

These advantages allow OEM customers to upgrade heating products to meet the demand for energy efficiency, comfort, and smart control.

1️⃣ Production Capacity and Manufacturing Strength

Our supply chain covers the full process from graphene material production to final film assembly.

Key Capacity Metrics

| Item | Capability Range |

|---|---|

| Monthly output | 500,000–1,000,000 m² heating films |

| Width | 300–1300 mm continuous roll |

| Length | up to 500 meters per roll |

| Thickness | 10–60 μm customizable |

| Production process | Roll-to-roll coating / printing / laminating |

| Quality inspection | 100% inline electrical testing |

High-level automation ensures stable sheet resistance and consistent heating performance batch-to-batch.

2️⃣ Custom Engineering for Global OEMs and Integrators

Our team supports technical customization from material, structure, to electrical performance.

Customizable Parameters

| Category | Options |

|---|---|

| Heating pattern | Etched film, printed film, busbar design |

| Sheet resistance | 5–1000 Ω/sq based on temp requirements |

| Operating voltage | 5V / 12V / 24V / 48V / 110V / 230V |

| Max temperature | 40°C–250°C |

| Substrate materials | PET, PI, Fe-Al, glass fiber, textiles |

| Surface finishing | Waterproof, insulation, adhesive backing |

| Smart control | NTC integration, temperature sensors |

We can assist clients in meeting UL, IEC, CE and local certification requirements.

3️⃣ Application-Specific Heating Film Solutions

Below are our most common custom solutions based on industry needs:

| Industry | Heating Film Solution | Key Performance |

|---|---|---|

| EV & Automotive | Demisting, de-icing, battery heating | Fast response, -40°C operation |

| Smart Home & HVAC | Floor heating, wall panels, bathroom mirror defogging | Uniform, energy-saving, large-size printing |

| Wearable & Healthcare | Heating jackets, knee pads, rehabilitation pads | Flexible, breathable, low voltage |

| Appliances | Smart tea heaters, food warmers | Rapid heating, low power |

| Aerospace & Drones | Ice prevention on sensors/blades | Lightweight, high reliability |

| Industrial Processing | Pipe heating, thermal compensation | Stable heating at high temp |

We also provide co-development services for customer-specific products.

4️⃣ Quality Control and Reliability Testing

To ensure long service life and high safety, we perform:

-

Continuous power heating aging test

-

Bending and fatigue testing (up to 100,000 cycles)

-

Water and insulation resistance tests

-

Thermal shock test

-

Surface breakdown voltage test

-

Peel strength for laminated films

Performance can be retained even after mechanical deformation and extreme climate stress.

5️⃣ Small-Batch Support for Prototyping and Market Testing

Many SME customers need flexible order conditions before full commercialization.

We offer:

✔ Sample fabrication (custom within 7–15 working days)

✔ Pilot batches for device integration

✔ Engineering support for temperature mapping

✔ Product design suggestions for certification readiness

This helps customers reduce development risk and accelerate time to market.

6️⃣ Smart Heating System Integration

To support manufacturers building smart heating ecosystems, we also provide:

-

Custom-soldered busbars & terminals

-

Thermistor/NTC embedding

-

PCB control modules (PWM/temperature control)

-

Bluetooth/WiFi/APP integration options

This enables IoT-enabled heating systems for modern smart homes and EVs.

Why Work With a Professional Heating Film Manufacturer?

Companies transitioning from traditional heating technologies face:

-

Lack of graphene design experience

-

Unfamiliarity with electrical safety compliance

-

Thermal uniformity optimization challenges

We act as your engineering partner, not only a materials supplier.

Graphene heating film is becoming a key technology for:

-

High-efficiency heating

-

Lightweight and flexible systems

-

Smart-controlled comfort experiences

With strong production capacity and full-range customization services, we support global customers—from concept design to mass production.

Whether you’re developing next-gen EV solutions, smart home systems, or flexible wearable products, our engineering team can help you build a high-performance, safe, and commercially competitive heating solution.