Graphene for EMI Shielding – How It Protects Electronic Devices

As modern electronics continue to shrink in size while operating at higher frequencies, electromagnetic interference (EMI) has become a growing challenge in every sector—from consumer devices to aerospace systems. Traditional metal-based shielding materials remain widely used but face limitations, especially in applications requiring lightweight, flexible, or corrosion-resistant designs.

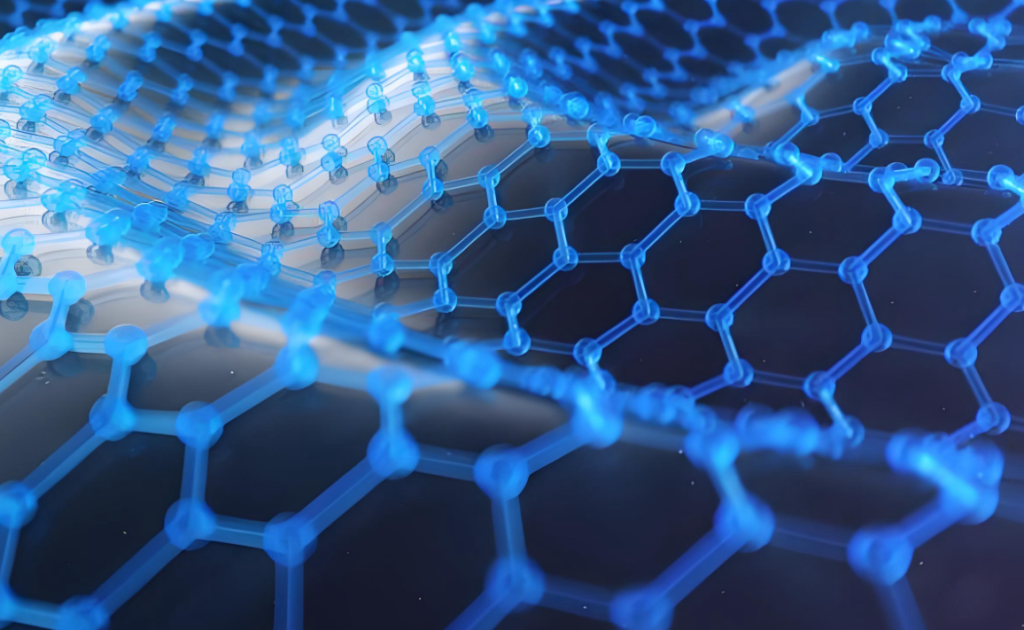

Graphene, with its exceptional electrical, mechanical, and thermal properties, is rapidly emerging as a superior EMI shielding material. This article explores how graphene provides EMI protection, how it compares to metals, and where it is being deployed today.

1. Why EMI Shielding Is Becoming More Critical

Electronic devices now operate in environments with:

• Higher frequencies

5G, IoT, high-speed processors, and radar systems generate stronger electromagnetic fields.

• Miniaturized circuits

PCBs, chips, and connectors are placed closer together, increasing crosstalk risk.

• Lightweight design requirements

Drones, EVs, satellites, and wearables cannot afford the weight of metals.

• Sensitive electronic sensors

Modern sensors operate at microvolt-level signals, easily disturbed by EMI.

Traditional metals such as copper, aluminum, and nickel work well but introduce issues like weight, rigidity, corrosion, and manufacturing limitations.

Graphene offers a new path forward.

2. Why Graphene Is a Powerful EMI Shielding Material

Graphene provides EMI shielding through reflection, absorption, and multiple scattering of electromagnetic waves.

Key advantages include:

✔ High electrical conductivity

Allows efficient reflection of electromagnetic waves, similar to metals.

✔ Extremely large specific surface area (~2630 m²/g)

Enhances wave absorption through multiple reflections inside graphene layers.

✔ Lightweight

Graphene composites are 10–100× lighter than metal foils.

✔ Flexibility and mechanical strength

Ideal for flexible electronics, curved casings, wearable devices, and films.

✔ Corrosion resistance and chemical stability

Unlike metals, graphene does not oxidize or degrade.

✔ Thermal stability

Maintains performance in high-temperature environments such as aerospace or EVs.

This combination makes graphene one of the most versatile EMI shielding materials available.

3. Forms of Graphene Used for EMI Shielding

Graphene can be engineered into multiple material formats depending on application requirements.

3.1 Graphene Films

Thin, conductive layers made through coating or CVD processes.

Applications:

-

Flexible displays

-

Foldable phones

-

PCB shielding films

-

Wearable electronics

3.2 Graphene–Polymer Composites

Graphene powder mixed with PP, ABS, epoxy, nylon, or TPU.

Benefits: strong, light, moldable, and suitable for injection molding.

Uses:

-

Device housings

-

Automotive electronics

-

Industrial sensors

3.3 Graphene Foams and Aerogels

Ultra-light porous structures with strong absorption capabilities.

Typical SE: 80–110 dB

Uses: aerospace, high-frequency communication systems.

3.4 Graphene Papers and Laminates

Layered graphene sheets compressed into high-density mats.

Uses:

-

Drone housings

-

EV components

-

High-end industrial electronics

3.5 Hybrid Graphene Composites

Graphene combined with carbon nanotubes (CNTs), metals, or MXenes.

Benefits: improved mechanical strength, conductivity, and broadband shielding.

4. Shielding Effectiveness of Graphene Materials

Shielding effectiveness (SE) is measured in decibels (dB):

| Graphene Material Type | Typical SE Range |

|---|---|

| Graphene film | 20–40 dB |

| Polymer–graphene composite | 30–60 dB |

| Graphene–CNT hybrid | 40–80 dB |

| Graphene foam/aerogel | 80–110 dB |

For reference:

-

20–40 dB → Consumer devices

-

40–80 dB → Automotive & industrial electronics

-

80–110 dB → Aerospace, radar, defense

Graphene systems can match or exceed metal shielding at a fraction of the weight.

5. How Graphene Outperforms Traditional Metals

• Weight Reduction

Graphene composites are typically 5–20% of the density of metal foils.

• Flexibility

Ideal for flexible circuits and wearable devices.

• Corrosion-Free

Suitable for harsh environments where metal corrosion is unacceptable.

• Tunable Properties

Electrical conductivity, mechanical strength, and EMI performance can be adjusted via:

-

flake size

-

layer number

-

dispersion quality

-

filler ratios

• Thin and Transparent Options

Graphene films can be nearly invisible while providing EMI protection—something metals cannot offer.

6. Industries Adopting Graphene EMI Shielding

6.1 Consumer Electronics

-

Smartphones

-

Tablets

-

Laptops

-

Smartwatches

Graphene films and coatings reduce weight while maintaining signal stability.

6.2 Electric Vehicles

EMI issues affect:

-

BMS

-

high-current circuits

-

sensors

-

infotainment systems

Graphene composites help reduce weight and improve reliability.

6.3 Aerospace and Defense

-

Radar systems

-

Satellites

-

Avionics

-

Drone electronics

Graphene foams and laminates offer ultra-light, high-performance EMI solutions.

6.4 5G / RF Communications

Graphene helps maintain signal integrity in high-frequency systems where metals often lose effectiveness.

6.5 Medical Electronics

Graphene composites provide stable shielding without metal toxicity or corrosion risk.

7. Challenges and Considerations

Graphene EMI shielding adoption depends on several factors:

1) Dispersion Quality

Well-dispersed graphene with minimal agglomeration provides far better EMI performance.

2) Flake Size and Layer Number

-

Larger flakes → higher electrical conductivity

-

Few-layer graphene → better absorption

3) Processing Method Compatibility

Must match industry manufacturing techniques like:

-

injection molding

-

extrusion

-

coating

-

film casting

4) Cost vs. Performance

Industrial-grade graphene composites are increasingly cost-competitive with metals—but require volume production for best economics.

8. Future Outlook

Graphene is expected to grow significantly in EMI shielding markets driven by:

-

flexible and foldable electronics

-

lightweight EV components

-

high-frequency 5G/6G communication devices

-

miniaturized medical sensors

-

aerospace and satellite systems

Research is advancing toward:

-

graphene–MXene hybrid systems

-

transparent EMI films for displays

-

graphene fabrics for wearable electronics

Graphene is positioned to replace metals in many next-generation EMI applications.

Graphene is transforming EMI shielding by offering a combination of lightweight performance, high conductivity, flexibility, and resistance to corrosion. As electronics continue to advance, traditional metal materials will increasingly struggle to meet weight and form-factor challenges. Graphene and graphene-based composites provide a strong, scalable, and cost-effective alternative—suitable for industries ranging from consumer electronics to aerospace.