Graphene for Electrically Conductive Coatings – Industrial Applications

Electrically conductive coatings are used across industries to provide antistatic protection, EMI shielding, electrical grounding, heating functionality, and enhanced durability. Traditional conductive additives—carbon black, metal powders, and conductive polymers—remain widely used, but they face limitations in conductivity, stability, and mechanical performance.

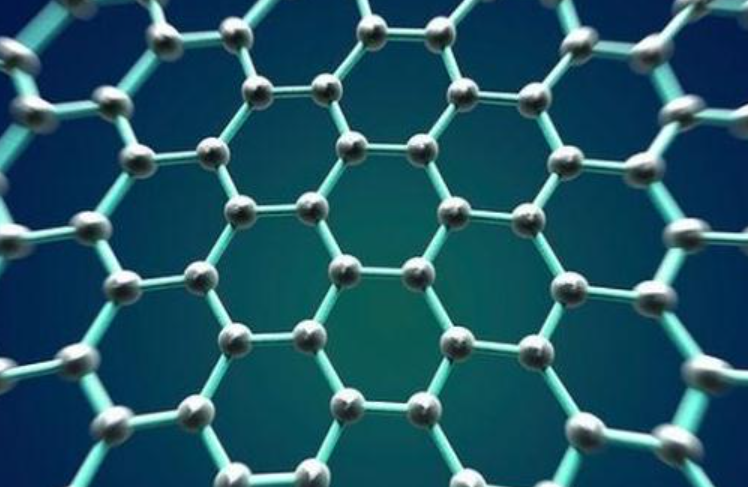

Graphene, with its unique two-dimensional carbon structure, is now emerging as a next-generation conductive material. Its exceptional conductivity, high surface area, mechanical strength, and barrier performance allow manufacturers to achieve multifunctional coatings with lower additive loading and better performance.

This article explores how graphene improves conductive coatings, the types of graphene used, major application fields, and what industries can expect next.

1. Why Use Graphene in Conductive Coatings?

1.1 Exceptional Electrical Conductivity

Graphene’s intrinsic conductivity can exceed 1,000,000 S/m, far higher than most carbon materials.

Even at low loading (0.1–2 wt%), it forms robust conductive pathways.

Benefits:

-

Lower dosage

-

Lower viscosity impact

-

Higher film uniformity

1.2 Low Percolation Threshold

Graphene flakes create wide, planar conductive networks.

Typical percolation threshold: 0.05–0.5 wt% (vs. 5–20 wt% for carbon black).

This enables:

-

Lightweight formulations

-

Clearer or semi-transparent coatings

-

Better mechanical flexibility

1.3 Mechanical Reinforcement

Graphene boosts:

-

Hardness

-

Abrasion resistance

-

Elasticity

-

Crack resistance

Coatings become more durable and maintain conductivity under bending and stretching.

1.4 Barrier and Corrosion Protection

Graphene is nearly impermeable to gases.

This gives coatings improved:

-

Chemical resistance

-

Corrosion resistance

-

Moisture barrier performance

Especially useful for metal structures and automotive components.

1.5 Thermal Properties

Graphene offers high thermal conductivity (>2,000 W/m·K), letting coatings function for:

-

Heating

-

Thermal spreading

-

High-temperature environments

2. Types of Graphene Used in Coatings

2.1 Graphene Nanoplatelets (GNPs)

Most cost-effective option.

Used for:

-

ESD coatings

-

EMI shielding

-

Conductive primers

-

Heating coatings

2.2 Reduced Graphene Oxide (rGO)

Offers good conductivity and dispersibility.

Ideal for:

-

Water-based coatings

-

Printable conductive inks

2.3 Few-Layer Graphene

Premium grade used where high transparency or ultra-low resistivity is required.

Applications:

-

Transparent conductive coatings

-

Advanced electronics

-

Wearable devices

3. Formulation Considerations

3.1 Dispersion Techniques

To avoid agglomeration:

-

High-shear mixing

-

Ultrasonic dispersion

-

Surface-functionalized graphene

-

Dispersing agents

Proper dispersion is the key to stable conductivity.

3.2 Solvent-Based Systems

Compatible with:

-

Epoxy

-

Polyurethane

-

Acrylic

Used in industrial, automotive, and metal coatings.

3.3 Water-Based Systems

Growing rapidly due to environmental regulations.

Requires hydrophilic or functionalized graphene.

3.4 Hybrid Systems

Graphene + CNTs + Carbon Black

→ Better conductivity and reduced cost.

4. Industrial Applications

4.1 Antistatic (ESD) Coatings

Graphene provides stable surface resistivity in the 10⁶–10⁹ Ω/sq range.

Used in:

-

Electronics manufacturing

-

Packaging trays

-

Semiconductor equipment

-

Fuel systems

-

Powder-coating lines

4.2 EMI/RFI Shielding Coatings

Graphene-based coatings offer 20–60 dB shielding depending on thickness.

Applications:

-

Aerospace avionics

-

EV electronics

-

Consumer devices

-

Industrial sensors

Graphene provides lightweight, corrosion-resistant alternatives to metal coatings.

4.3 Conductive Primers for Metals

Benefits:

-

Improved grounding

-

Corrosion barrier

-

Better adhesion

Used for:

-

Marine structures

-

Wind turbine towers

-

Power grid equipment

-

Structural steel

4.4 Heating Coatings (Joule Heating)

Graphene allows low-voltage heating coatings with uniform temperature.

Applications:

-

Anti-icing surfaces

-

EV windshield defogging

-

Battery thermal regulation

-

Medical heating pads

4.5 Transparent or Semi-Transparent Conductive Coatings

Not as conductive as metal oxides but far more flexible.

Used in:

-

Smart windows

-

Flexible touch sensors

-

Transparent heaters

-

Wearables

4.6 Energy Storage and Conductive Electrodes

Graphene improves:

-

Collector plate conductivity

-

Adhesion

-

Cycle stability

Used in:

-

Li-ion batteries

-

Supercapacitors

-

Fuel cells

5. Key Performance KPIs

| Metric | Graphene Advantage |

|---|---|

| Surface Resistivity | 10³–10⁸ Ω/sq |

| Loading | 0.1–3 wt% |

| Hardness | +20–60% |

| EMI Shielding | Up to 60 dB |

| Thermal Stability | Up to 400–500°C |

| Bending Cycles | >500 cycles without cracking |

6. Challenges and Solutions

6.1 Dispersion Stability

Solution: Functionalized graphene, controlled flake size, surfactants.

6.2 Cost Optimization

Solution: Hybrid systems (graphene + CB + CNTs).

6.3 Consistency

Solution: Use narrow-range flake size, stable supply chain partners.

7. Market Outlook

-

Driven by EVs, aerospace, 5G, wearables, and industrial electronics.

-

Water-based conductive coatings are expanding fastest.

-

Graphene heating coatings expected to grow sharply from 2025–2030.

-

The global conductive coatings market is projected to exceed $3–4 billion by 2030, with graphene taking a growing share.

Graphene is revolutionizing conductive coatings by delivering superior electrical conductivity, mechanical strength, and multifunctional performance at lower loading levels. Its ability to combine conductivity, durability, thermal management, and corrosion protection makes it an unmatched next-generation material for industrial coatings. As production scales and costs decline, graphene-based conductive coatings will become increasingly mainstream across high-tech and heavy industries.