Transparent Conductive Films – How Graphene Challenges ITO

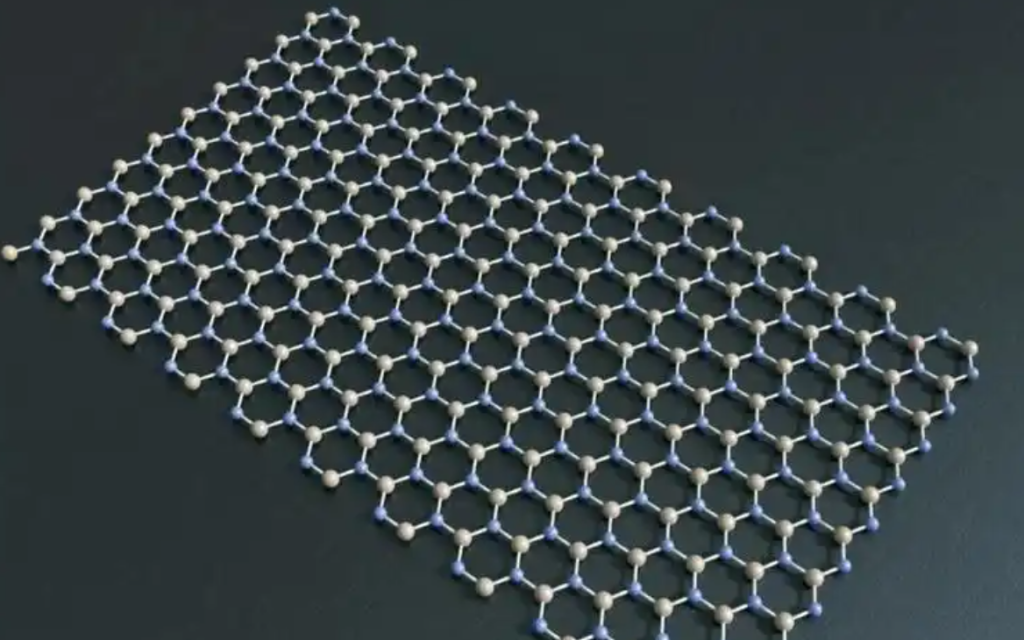

Why Graphene Is Becoming the Next-Generation Material for Touchscreens, Displays, and Flexible Electronics

Transparent conductive films (TCFs) are essential materials in modern electronics. They enable touchscreens to sense touch, displays to operate uniformly, solar cells to collect charges, and LEDs to maintain uniform brightness. For decades, the market has been dominated by Indium Tin Oxide (ITO)—but ITO has become increasingly incompatible with the industry’s push toward flexibility, durability, sustainability, and lower cost.

Graphene, with its combination of transparency, conductivity, strength, and flexibility, is emerging as the most promising alternative to ITO. Although still evolving toward mass industrial deployment, graphene-based TCFs are now entering commercial applications in wearables, flexible displays, sensors, and transparent heaters.

This article explains why graphene challenges ITO, how it performs as a TCF, manufacturing methods, current limitations, and where the technology is heading next.

1. Why ITO Is No Longer Enough

ITO has served as the standard transparent conductor for more than 20 years, but it suffers from several structural and economic limitations.

1.1 ITO Is Brittle

-

ITO cracks easily

-

Conductivity drops sharply when bent

-

Cannot be used on flexible or foldable devices

Today’s electronics require curved, foldable, rollable, stretchable designs—ITO simply cannot keep up.

1.2 Indium Is Expensive and Limited

Indium is a rare metal with unstable global supply. Prices fluctuate heavily, making ITO a risky long-term solution for large-scale industries.

1.3 High Processing Temperature

ITO typically requires 200–400°C deposition, incompatible with low-cost substrates such as PET films.

1.4 Poor Durability Under Repeated Stress

ITO films degrade due to:

-

Repeated bending

-

Mechanical vibration

-

Scratching

-

Temperature cycling

This is unacceptable for wearable electronics and automotive interfaces.

2. How Graphene Solves These Limitations

Graphene offers a unique combination of properties unmatched by any existing transparent conductor.

| Property | Graphene | ITO |

|---|---|---|

| Transparency | 97–98% | 85–90% |

| Sheet resistance | 30–300 Ω/sq (1–3 layers) | 10–100 Ω/sq |

| Flexibility | Can withstand 10,000+ bending cycles | Breaks after a few cycles |

| Strength | 200× stronger than steel | Brittle |

| Thermal stability | Excellent | Moderate |

| Material cost | Falling steadily | Rising (indium scarcity) |

Graphene does not yet match ITO’s lowest sheet resistance in high-end applications, but for many sectors the trade-off is worth it due to flexibility, cost, and durability.

3. Manufacturing Methods for Graphene TCFs

For transparent conductive film applications, two dominant graphene production technologies exist:

3.1 CVD Graphene (Chemical Vapor Deposition)

The most widely used method for high-quality graphene films.

Process:

-

Grow graphene on copper foil via CVD

-

Coat with polymer support

-

Etch copper

-

Transfer graphene to transparent substrate

Advantages:

-

High transparency

-

Low sheet resistance

-

Uniform over large areas

Challenges:

-

Transfer process adds cost

-

Potential micro-cracks during transfer

-

Multi-layer stacking needed for low resistance

Used in:

✔ Touch sensors

✔ Smart windows

✔ Transparent heaters

3.2 Liquid-Phase Exfoliated (LPE) Graphene / Graphene Ink

Graphene flakes are printed or coated onto flexible film substrates.

Advantages:

-

Low cost

-

Scalable, roll-to-roll production

-

Good for large-area, moderate-resistance applications

Sheet resistance: 200–2000 Ω/sq

Transparency: 85–95%

Used in:

✔ Printed sensors

✔ Wearable patches

✔ Low-power transparent heaters

✔ ESD coatings

4. Performance of Graphene Transparent Conductive Films

4.1 Electrical Conductivity

Electrons move extremely fast through graphene, making conductivity stable even under mechanical deformation.

Multi-layer graphene films (3–10 layers) achieve:

-

30–150 Ω/sq at 90% T

-

Suitable for touch panels, heaters, and sensors

4.2 Mechanical Durability

Graphene TCFs survive:

-

10,000+ bending cycles

-

Folding down to 1–5 mm radius

-

Scratches without conductivity loss

ITO fails after fewer than 100–500 cycles.

4.3 Optical Transparency

A single layer of graphene absorbs only 2.3% of visible light. Even multilayer stacks maintain >90% transparency.

This makes graphene ideal for displays and AR/VR interfaces.

4.4 Lightweight and Thin

Graphene’s thickness is ~0.34 nm (one atom layer).

ITO is typically 100–200 nm.

This allows thinner, brighter, more energy-efficient displays.

5. Graphene vs ITO – Application-by-Application Comparison

5.1 Touchscreens (Resistive & Capacitive)

-

Graphene resists cracking

-

Works with curved and foldable panels

-

Stable response over temperature cycles

Winner: Graphene for flexible devices; ITO still common for rigid screens.

5.2 Wearables & Flexible Electronics

Graphene excels in:

-

Smart clothing

-

Skin sensors

-

Medical monitoring patches

-

Flexible LED strips

-

Foldable phones

ITO not usable at all.

5.3 Transparent Heaters

Graphene produces:

-

Uniform heating

-

High temperature stability

-

No hot spots

Applications:

-

Automotive windshields

-

Camera lens heaters

-

Cold-weather wearable heaters

-

Anti-fog smart mirrors

-

Battery anti-condensation films

5.4 Solar Cells

Graphene improves:

-

Charge collection

-

Weather durability

-

Flexibility of thin-film PV

Especially promising in perovskite solar cells.

5.5 Smart Windows & Architectural Glass

Graphene enables:

-

Infrared modulation

-

Transparent heaters

-

Anti-fog/anti-icing coatings

ITO’s brittleness limits large-scale architectural use.

6. Limitations of Graphene Transparent Conductive Films

Although progress is rapid, several challenges remain.

6.1 Sheet Resistance Still Higher Than ITO (in some cases)

High-end OLED and LCD manufacturing requires sheet resistance <10 Ω/sq.

Graphene typically delivers 30+ Ω/sq.

However, hybrid structures—graphene + metal grids, graphene + silver nanowires—already reduce this gap.

6.2 Transfer Costs (CVD Films)

Copper etching and transfer steps add cost and complexity.

Yet roll-to-roll CVD is scaling quickly and reducing cost.

6.3 Uniformity and Flake Size (Ink Films)

Graphene ink films have higher roughness and lower conductivity, limiting high-end display use.

7. The Future: Why Graphene Will Eventually Replace ITO

✔ Rising demand for flexible devices

Foldable phones and rollable displays cannot use ITO.

✔ Improving graphene processing

Roll-to-roll CVD now produces meter-scale uniform films.

✔ Lower cost from mass-scale production

More countries are building graphene production lines; cost is dropping annually.

✔ Hybrid conductive films

Graphene combined with:

-

metallic nanowires

-

conductive polymers

-

thin metal meshes

Already outperform ITO in some areas.

✔ Environmental & supply chain stability

Graphene is carbon—abundant and recyclable.

ITO has served the electronics industry well, but it cannot meet the next generation’s requirement for durability, flexibility, and sustainability. Graphene, with its exceptional mechanical flexibility, transparency, and stable conductivity, is becoming the leading candidate to replace ITO across many application segments.

Already, graphene transparent conductive films are commercially used in:

-

Wearables

-

Smart windows

-

Automotive glass heaters

-

Flexible sensors

-

Printed electronics

As production scale grows and sheet resistance continues to drop, graphene will become the mainstream transparent conductor for the flexible electronics era.