Comparing CNT vs Carbon Black in Static Dissipation Plastics

1. Introduction: The Role of Static Dissipation in Plastics

Static dissipation plastics are widely used to prevent electrostatic charge accumulation in applications such as electronic packaging, industrial housings, cleanroom components, and precision devices. Unlike conductive plastics, static dissipative materials aim to control charge decay safely, typically within a surface resistivity range of 10⁶–10⁹ Ω/sq.

Achieving stable static dissipation requires a carefully engineered conductive network that balances electrical performance, mechanical properties, processability, and cost. Traditionally, carbon black has been the dominant conductive filler. However, carbon nanotubes (CNTs) are increasingly adopted to overcome carbon black’s limitations.

2. Electrical Requirements for Static Dissipation Plastics

Static dissipative plastics must:

-

Prevent sudden electrostatic discharge

-

Maintain stable resistivity over time

-

Perform reliably under varying humidity and temperature

-

Avoid over-conductivity that could cause short circuits

This narrow conductivity window makes material selection particularly critical.

3. Carbon Black in Static Dissipation Plastics

3.1 Advantages of Carbon Black

Carbon black remains widely used due to:

-

Low cost

-

Mature processing technology

-

Reliable ESD performance at high loading

It is especially suitable for cost-sensitive, thick-walled components.

3.2 Limitations of Carbon Black

Despite its popularity, carbon black presents several challenges:

-

High percolation threshold

-

High filler loading (typically 10–20 wt%)

-

Significant impact on mechanical properties

-

Limited design freedom for thin or lightweight parts

High loading often results in increased viscosity and reduced impact strength.

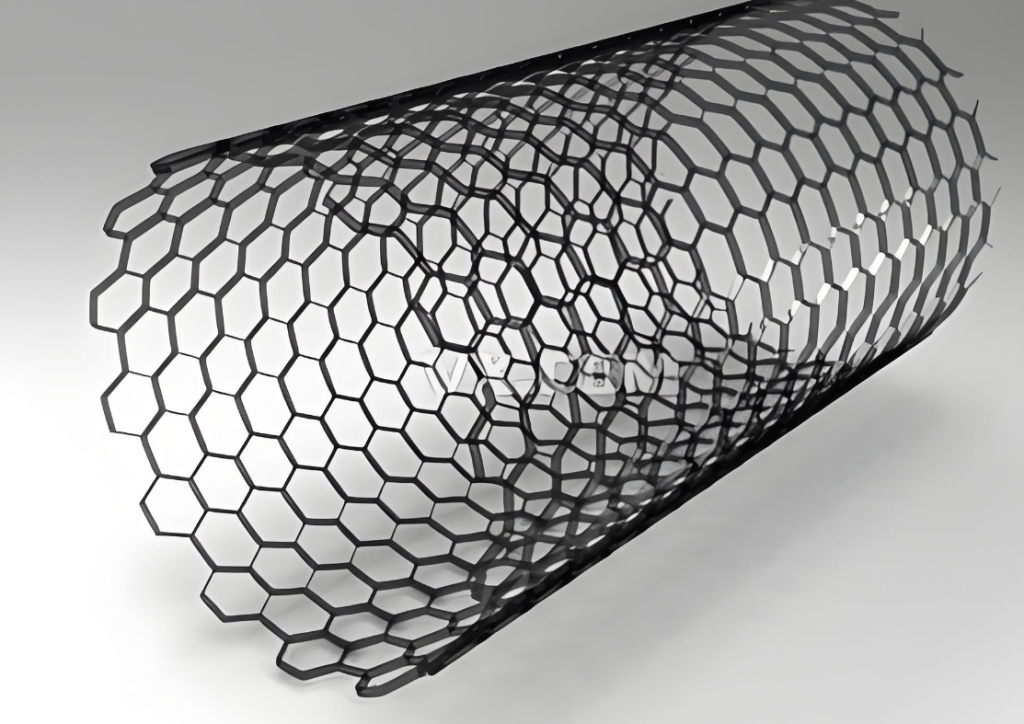

4. CNTs in Static Dissipation Plastics

4.1 Low Percolation Threshold

CNTs form conductive networks at very low loadings (often <1 wt%), enabling:

-

Stable static dissipation

-

Reduced material modification

-

Greater formulation flexibility

4.2 Mechanical Property Retention

Due to low required loading, CNT-filled plastics retain:

-

Tensile strength

-

Elongation

-

Fatigue resistance

This is critical for precision and thin-walled components.

4.3 Stability Under Environmental Variation

CNT networks show:

-

More stable resistivity across humidity changes

-

Improved long-term electrical consistency

This reduces performance drift in real-world environments.

5. Processing and Manufacturing Considerations

5.1 Dispersion

-

Carbon black disperses easily with conventional equipment

-

CNTs require controlled dispersion strategies

However, once dispersed, CNT systems show greater network stability.

5.2 Moldability and Flow

High carbon black loading increases melt viscosity, potentially limiting:

-

Thin-wall molding

-

Complex geometries

CNT-based systems maintain better flow properties.

6. Comparative Performance Summary

| Parameter | Carbon Black | CNT |

|---|---|---|

| Typical loading | 10–20 wt% | 0.1–1 wt% |

| Mechanical impact | High | Low |

| Resistivity stability | Moderate | High |

| Thin-wall capability | Limited | Excellent |

| Environmental stability | Moderate | High |

| Cost per kg | Low | Higher |

| Cost per performance | Moderate | Favorable |

7. Hybrid CNT–Carbon Black Systems

Many manufacturers adopt hybrid systems combining:

-

Carbon black for cost efficiency

-

CNTs to reduce percolation threshold and stabilize conductivity

Hybrid formulations often deliver the best balance between cost and performance.

8. Application-Based Selection Guide

-

ESD packaging trays: Carbon black or hybrid systems

-

Thin-wall electronics housings: CNT-based systems

-

Precision molded parts: CNT preferred

-

Cost-driven bulk components: Carbon black

9. Long-Term Reliability and Product Lifetime

CNT-based static dissipative plastics show:

-

Lower conductivity drift

-

Improved resistance to mechanical fatigue

-

More predictable performance over product lifetime

These advantages reduce quality risk in sensitive applications.

Carbon black remains a practical and cost-effective solution for many static dissipation plastic applications. However, its high loading requirements and impact on mechanical properties limit its suitability for advanced designs.

Carbon nanotubes offer a superior alternative by enabling stable static dissipation at significantly lower loading levels, improving mechanical performance, design freedom, and long-term reliability.

For manufacturers seeking consistent ESD performance in lightweight or precision plastic components, CNT-based static dissipation systems represent a clear technological upgrade.