Self-Healing Protective Coatings with 2D Nanomaterials

1. From Passive Protection to Active Coatings

Traditional protective coatings function as passive barriers, relying on thickness and adhesion to isolate substrates from corrosive or mechanical damage. However, once micro-cracks or defects appear, protection rapidly degrades.

Self-healing coatings represent a shift toward active protection systems, capable of responding to damage autonomously. The integration of 2D nanomaterials, such as graphene and related layered materials, has opened new pathways to enhance both barrier performance and healing efficiency.

2. What Is a Self-Healing Coating?

A self-healing coating can:

-

Detect micro-scale damage

-

Restore barrier integrity without external intervention

-

Extend coating service life

Healing mechanisms can be intrinsic (material-driven) or extrinsic (triggered by embedded agents).

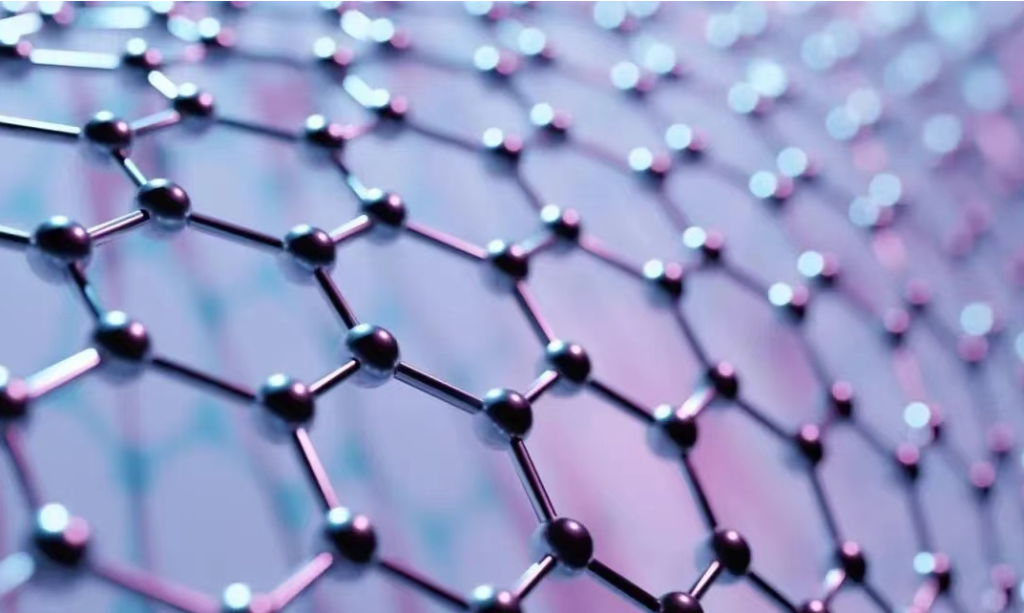

3. Why 2D Nanomaterials Are Relevant

2D nanomaterials exhibit:

-

Extremely high aspect ratio

-

Layered, platelet-like geometry

-

Low permeability to gases and ions

-

High mechanical reinforcement efficiency

These features make them ideal for crack control, diffusion blocking, and stress redistribution within coating systems.

4. Common 2D Nanomaterials Used in Self-Healing Coatings

| Material | Key Function |

|---|---|

| Graphene / GNPs | Barrier enhancement, crack deflection |

| Graphene Oxide (GO) | Interfacial bonding, stimulus response |

| h-BN | Thermal stability, electrical insulation |

| MXenes | Conductivity, electrochemical response |

Material choice depends on healing trigger, environment, and functional requirements.

5. Self-Healing Mechanisms Enabled by 2D Nanomaterials

5.1 Crack Deflection and Arrest

2D nanosheets act as physical obstacles:

-

Force cracks to deviate

-

Increase crack propagation path

-

Reduce crack growth rate

This does not “heal” the crack but slows failure significantly.

5.2 Polymer Chain Mobility Enhancement

Some 2D materials (e.g., GO) enhance interfacial interactions:

-

Promote reversible hydrogen bonding

-

Improve polymer chain rearrangement

This supports intrinsic self-healing at moderate temperatures or stress conditions.

5.3 Stimuli-Responsive Healing

2D nanomaterials can enable healing triggered by:

-

Heat

-

Electrical current

-

Moisture or pH change

For example, electrically conductive graphene networks can generate localized Joule heating, accelerating polymer flow and healing.

6. Barrier Synergy: Healing + Protection

2D nanomaterials improve coating performance even before healing:

-

Increase tortuosity of diffusion paths

-

Reduce oxygen, water, and ion permeation

-

Maintain protection during partial damage

This synergy allows coatings to retain protection even with minor defects.

7. Design Parameters for Self-Healing Coatings

7.1 Filler Loading

-

Too low → insufficient barrier effect

-

Too high → reduced flexibility and healing efficiency

Optimal loading balances mechanical reinforcement and chain mobility.

7.2 Dispersion Quality

Uniform dispersion ensures:

-

Consistent crack interaction

-

Predictable healing behavior

Agglomeration creates stress concentrators that degrade performance.

7.3 Matrix Compatibility

Common matrices include:

-

Epoxy systems

-

Polyurethane

-

Acrylic and hybrid resins

Matrix chemistry determines healing activation conditions.

8. Comparison with Microcapsule-Based Systems

| Aspect | Microcapsule Systems | 2D Nanomaterial Systems |

|---|---|---|

| Healing cycles | One-time | Multi-cycle |

| Structural integrity | Potentially reduced | Maintained |

| Trigger | Crack rupture | Intrinsic / stimuli-based |

| System complexity | High | Moderate |

2D nanomaterials favor repeatable, long-term protection.

9. Application Areas

Self-healing coatings with 2D nanomaterials are relevant for:

-

Marine and offshore structures

-

Industrial pipelines

-

Energy storage enclosures

-

Aerospace and transportation

-

Infrastructure protection

They are particularly attractive in hard-to-maintain environments.

10. Manufacturing and Scale-Up Considerations

Key challenges include:

-

Stable dispersion at industrial scale

-

Compatibility with standard coating processes

-

Cost-performance optimization

Successful deployment depends on formulation engineering, not just material selection.

11. Future Development Trends

-

Hybrid self-healing systems (2D materials + dynamic polymers)

-

Multi-functional coatings (self-healing + anticorrosion + sensing)

-

Electrically triggered repair mechanisms

-

Long-term durability validation

2D nanomaterials enable a new generation of self-healing protective coatings by combining:

-

Crack control

-

Enhanced barrier properties

-

Stimuli-responsive healing mechanisms

Rather than acting as standalone solutions, these materials serve as functional enablers within carefully designed coating systems, offering extended service life and reduced maintenance demands.