Wear and Scratch Resistance Improvement in Industrial Coatings

1.Why Wear and Scratch Resistance Matter

In many industrial environments, coatings fail not due to corrosion alone, but because of mechanical damage such as abrasion, scratching, and repeated contact stress.

Once surface damage occurs, coatings rapidly lose their barrier and protective functions, accelerating corrosion and material degradation. Improving wear and scratch resistance is therefore a critical aspect of coating durability.

2. Wear vs Scratch: Understanding the Difference

Although often grouped together, wear and scratch involve different mechanisms:

-

Wear – progressive material removal due to repeated mechanical contact

-

Scratch – localized surface damage caused by a single or limited contact event

Effective coating design must address both mechanisms.

3. Key Factors Influencing Wear and Scratch Resistance

Coating performance is governed by:

-

Hardness and modulus

-

Toughness and crack resistance

-

Adhesion to substrate

-

Filler–matrix interaction

Simply increasing hardness often leads to brittleness and premature failure.

4. Limitations of Traditional Hard-Filler Approaches

Conventional strategies rely on:

-

Ceramic particles

-

High crosslink density

While hardness increases, these approaches often result in:

-

Reduced impact resistance

-

Poor flexibility

-

Microcrack formation under stress

This highlights the need for balanced material architectures.

5. Role of Nanomaterials in Wear-Resistant Coatings

Nanomaterials offer unique advantages:

-

High surface area reinforcement

-

Stress transfer at the nanoscale

-

Crack deflection and energy dissipation

When properly dispersed, they improve durability without excessive stiffness.

6. 2D and 1D Nanomaterials for Surface Protection

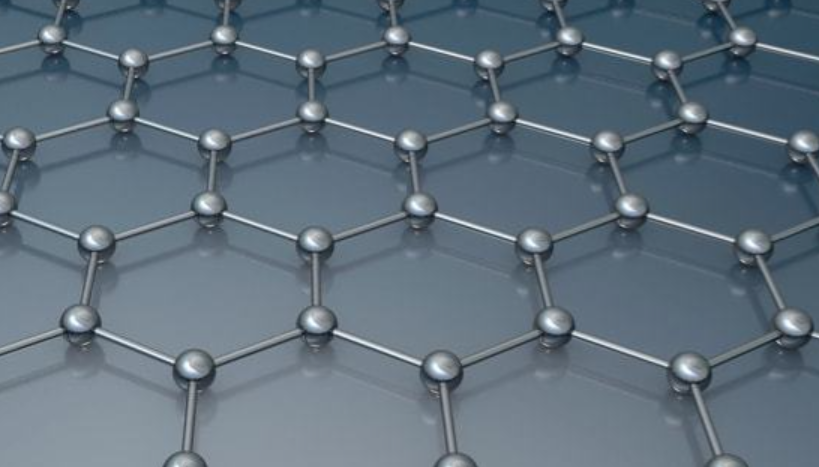

6.1 Graphene and Layered Materials

Graphene-based fillers provide:

-

Lamellar barrier structure

-

Reduced friction coefficient

-

Crack path deflection

Their platelet geometry is effective against scratch-induced delamination.

6.2 CNTs as Load-Bearing Reinforcements

CNTs contribute:

-

Load redistribution

-

Resistance to microcrack propagation

-

Enhanced elastic recovery

CNTs are particularly effective in repeated wear environments.

7. Synergistic Filler Architectures

Hybrid systems combine:

-

Graphene for surface barrier and scratch resistance

-

CNTs for toughness and wear endurance

Such systems improve performance across multiple damage modes.

8. Matrix Selection and Crosslinking Control

Matrix chemistry plays a decisive role:

-

Epoxy systems → hardness and chemical resistance

-

Polyurethane → flexibility and impact tolerance

-

Hybrid systems → balanced properties

Optimized crosslink density enhances wear resistance while preserving toughness.

9. Dispersion Quality and Interface Engineering

Poor dispersion leads to:

-

Stress concentration

-

Abrasive particle pull-out

-

Reduced coating lifetime

Surface-treated nanofillers and controlled mixing are essential for consistent performance.

10. Coating Thickness and Layer Design

Wear resistance is not solely thickness-dependent:

-

Thin, tough layers often outperform thick brittle coatings

-

Multi-layer designs can isolate mechanical stress

Layer architecture is as important as material selection.

11. Industrial Applications

Wear- and scratch-resistant coatings are critical in:

-

Industrial machinery

-

Automotive components

-

Marine and offshore structures

-

Energy equipment enclosures

-

Material handling systems

Durability directly impacts maintenance cycles and lifecycle cost.

12. Testing and Performance Evaluation

Common evaluation methods include:

-

Taber abrasion

-

Scratch resistance testing

-

Nanoindentation

-

Field durability trials

Lab data must correlate with real operating conditions.

13. Design Trade-Offs and Engineering Balance

Key trade-offs include:

-

Hardness vs toughness

-

Reinforcement vs processability

-

Performance vs cost

Successful formulations optimize system-level performance, not individual parameters.

Improving wear and scratch resistance in industrial coatings requires a balanced materials strategy.

By combining:

-

Appropriate matrix chemistry

-

Controlled crosslinking

-

Well-dispersed nano-reinforcements

coatings can achieve enhanced mechanical durability without sacrificing long-term reliability.