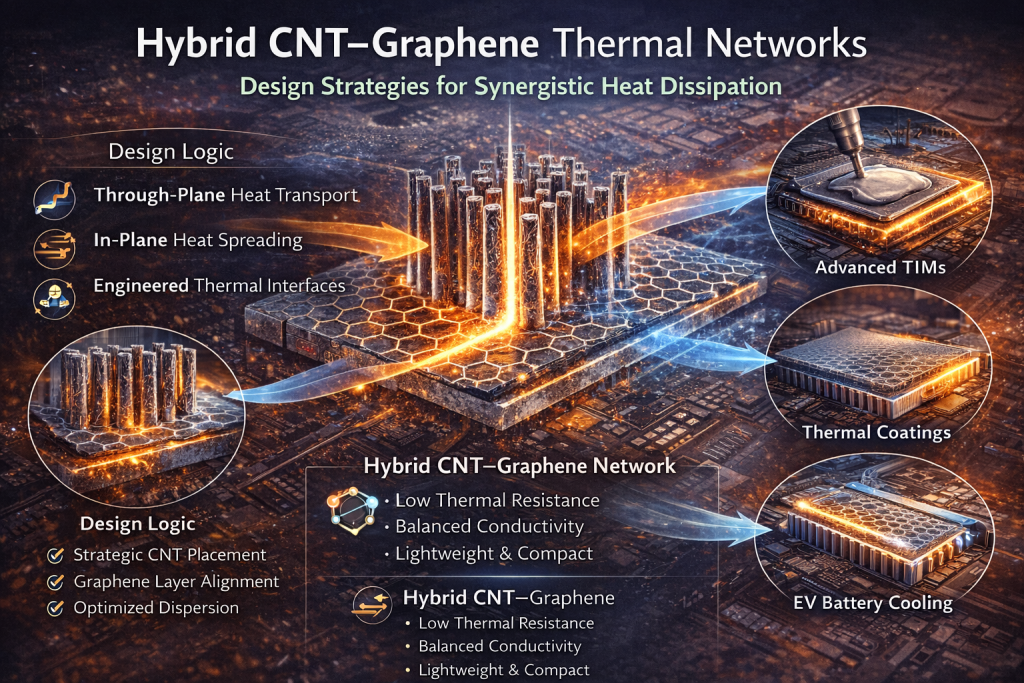

Hybrid CNT–Graphene Thermal Networks – Design Strategies

Why Hybrid Thermal Networks Matter

As power densities continue to rise in electronics, energy storage systems, and industrial equipment, thermal management has become a system-level constraint rather than a secondary consideration. Traditional fillers such as aluminum oxide or boron nitride often struggle to deliver sufficient thermal performance without compromising weight, thickness, or processability.

Carbon nanomaterials—particularly carbon nanotubes (CNTs) and graphene—offer exceptional intrinsic thermal conductivity. However, when used independently, each material exhibits limitations in real-world composite systems. This has led to growing interest in hybrid CNT–graphene thermal networks, which combine complementary transport mechanisms to achieve balanced and scalable heat dissipation solutions.

Thermal Transport in CNT and Graphene: Complementary Strengths

Graphene: In-Plane Heat Spreading

Graphene’s two-dimensional lattice enables extremely high in-plane thermal conductivity, making it ideal for lateral heat spreading across surfaces. In coatings, films, or thermal interface layers, graphene efficiently redistributes localized heat, reducing hot spots.

Limitations:

-

Poor through-plane heat transport

-

Tendency to restack, increasing interfacial thermal resistance

-

Limited effectiveness at low loading if dispersion is insufficient

Carbon Nanotubes: Through-Plane Heat Pathways

CNTs, with their one-dimensional tubular structure and high aspect ratio, are highly effective at forming vertical and three-dimensional conductive pathways. Properly dispersed CNTs can bridge interfaces, improving heat flow between layers or components.

Limitations:

-

Less effective for lateral heat spreading

-

Agglomeration risk at higher loadings

-

Processing challenges in polymers and coatings

Why Hybrid CNT–Graphene Networks Work Better

By combining CNTs and graphene, hybrid systems exploit synergistic thermal transport:

-

Graphene sheets spread heat laterally (in-plane)

-

CNT networks bridge layers and interfaces (through-plane)

-

CNTs act as “thermal connectors” between graphene platelets

-

Reduced percolation threshold compared to single-filler systems

The result is a continuous 3D thermal network with lower overall thermal resistance than CNT-only or graphene-only composites.

Key Design Strategies for Hybrid Thermal Networks

1. Dimensional Complementarity

Effective hybrid systems intentionally combine:

-

2D graphene (or few-layer graphene / GNPs) for surface heat spreading

-

1D CNTs for vertical thermal transport and network connectivity

The ratio between CNTs and graphene is critical—excessive CNT content may increase viscosity, while excess graphene may cause restacking.

2. Interface Engineering and Contact Resistance Reduction

Thermal performance in composites is often dominated by interfacial thermal resistance rather than intrinsic conductivity.

Design strategies include:

-

Using CNTs to bridge graphene-to-graphene interfaces

-

Surface functionalization (mild oxidation or surfactants) to improve filler–matrix contact

-

Hybrid dispersion techniques (e.g., sequential dispersion instead of co-mixing)

3. Orientation and Network Control

Thermal conductivity is anisotropic in hybrid systems.

Examples:

-

Aligned graphene + randomly dispersed CNTs for isotropic heat dissipation

-

Vertically aligned CNT arrays on graphene films for advanced TIMs

-

Controlled shear during coating or extrusion to orient graphene laterally

4. Processing Compatibility

Hybrid systems must remain compatible with industrial processing:

-

Melt compounding (thermoplastics)

-

Solution-based coatings and dispersions

-

Screen printing or spray coating for thermal films

-

Low-temperature curing for electronics and battery systems

Well-designed hybrids often achieve target performance at lower total filler loadings, preserving mechanical properties and processability.

Application Scenarios

Thermal Interface Materials (TIMs)

Hybrid CNT–graphene fillers reduce thermal contact resistance between chips, heat spreaders, and heat sinks while maintaining thin bond lines.

Battery Thermal Management

In lithium-ion battery modules, hybrid networks improve heat dissipation across cell surfaces, enhancing safety and cycle life.

Thermal Coatings

Hybrid coatings provide both thermal conductivity and mechanical robustness for power electronics enclosures, converters, and industrial control units.

Flexible and Lightweight Electronics

Compared to metal fillers, carbon-based hybrids offer high thermal performance with low density and excellent fatigue resistance.

Performance vs. Cost Considerations

| System | Thermal Efficiency | Loading Level | Cost Efficiency |

|---|---|---|---|

| Graphene only | High in-plane | Medium–High | Medium |

| CNT only | Good through-plane | Medium | Medium–High |

| Hybrid CNT–Graphene | Balanced 3D | Low–Medium | Optimized |

Hybrid systems often deliver the best performance-to-cost ratio, particularly when thermal management must be combined with electrical conductivity or mechanical durability.

Design Takeaways for Engineers and Material Developers

-

Thermal management is a network problem, not a single-material problem

-

CNTs and graphene solve different parts of the heat transport equation

-

Hybrid architectures enable performance tuning rather than compromise

-

Processing and dispersion strategy are as important as material selection

Hybrid CNT–graphene thermal networks represent a practical and scalable path toward next-generation thermal management solutions. By combining lateral heat spreading with vertical heat transport, these systems overcome the limitations of single-filler approaches and unlock new design freedom for coatings, films, composites, and interfaces.

As power density continues to rise across electronics, energy storage, and industrial systems, hybrid carbon nanomaterial design will increasingly define thermal performance boundaries.