CNT–Graphene TIMs vs. Traditional Fillers

Why Hybrid Carbon Networks Are Redefining Thermal Interface Materials

The Limits of Traditional TIM Fillers

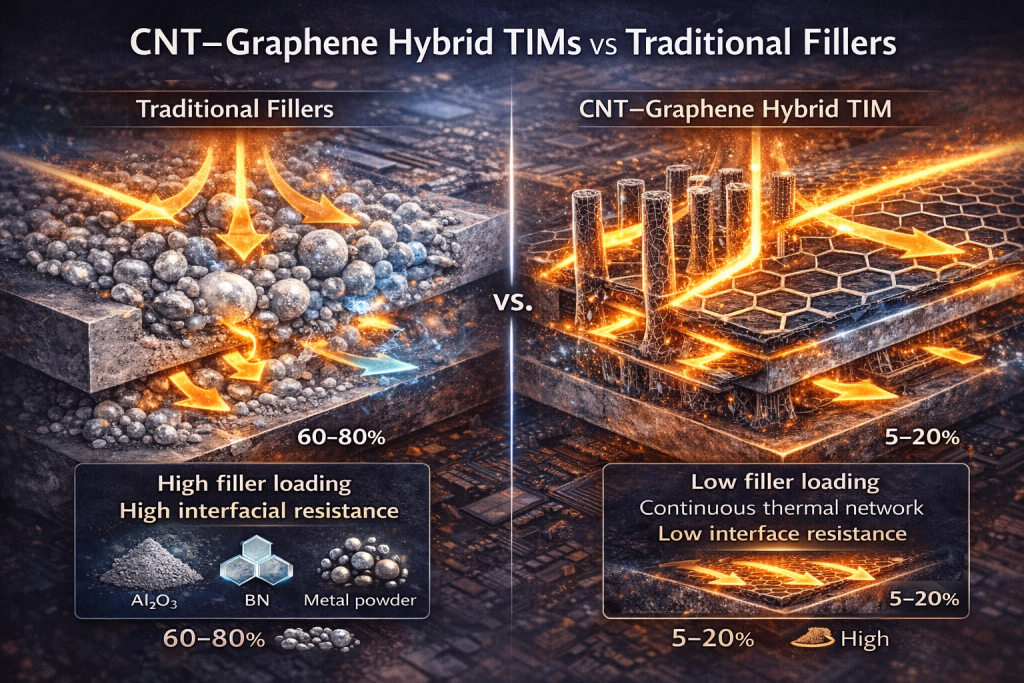

Thermal Interface Materials (TIMs) play a critical role in transferring heat from heat-generating components to heat sinks or spreaders. For decades, traditional fillers such as aluminum oxide (Al₂O₃), boron nitride (BN), and metal powders have dominated TIM formulations.

However, as device power density increases and form factors shrink, these conventional fillers are reaching their practical limits. The emergence of CNT–graphene hybrid fillers offers a fundamentally different approach to thermal interface design—one based on network efficiency rather than filler loading.

What Traditional TIM Fillers Do Well—and Where They Fail

Common Traditional Fillers

-

Aluminum oxide (Al₂O₃)

-

Boron nitride (h-BN)

-

Aluminum or silver particles

Strengths

-

Stable supply and mature processing

-

Electrically insulating options available

-

Predictable rheology at moderate loadings

Key Limitations

-

Require very high filler loading (50–80 wt%)

-

Increase viscosity dramatically

-

Poor compliance and surface conformity

-

Limited performance at thin bond lines

-

Weak thermal contact at micro-scale interfaces

In practice, traditional fillers rely on particle-to-particle contact, which creates multiple thermal resistance points across the interface.

How CNT–Graphene TIMs Work Differently

CNT–graphene TIMs are not particle-packed systems—they are network-engineered systems.

Hybrid Network Architecture

-

Graphene provides in-plane heat spreading at the interface

-

CNTs create vertical heat pathways and bridge micro-gaps

-

CNTs connect graphene sheets and anchor them into the matrix

This architecture forms a continuous 3D thermal conduction network at significantly lower filler content.

Key Performance Differences

1. Thermal Conductivity vs. Loading

| Filler System | Typical Loading | Effective Heat Transfer |

|---|---|---|

| Al₂O₃ | 60–75 wt% | Moderate |

| BN | 50–70 wt% | Moderate–High |

| Metal powders | 50–80 wt% | High (with drawbacks) |

| CNT–Graphene Hybrid | 5–20 wt% | High & Efficient |

Lower loading translates directly to:

-

Better flow

-

Thinner bond lines

-

Improved surface wetting

2. Thermal Contact Resistance

Traditional fillers struggle with microscopic surface roughness, leaving air gaps that act as thermal insulators.

CNT–graphene TIMs:

-

Conform to surface irregularities

-

Bridge nano- and micro-scale voids

-

Maintain contact under pressure and thermal cycling

This often results in lower overall thermal resistance, even if bulk conductivity numbers appear similar.

3. Mechanical Compliance and Reliability

High filler loading makes traditional TIMs:

-

Brittle

-

Prone to pump-out

-

Sensitive to vibration and cycling

Hybrid carbon TIMs offer:

-

Elastic compliance

-

Crack resistance

-

Stable performance under thermal cycling

This is especially critical in:

-

EV power electronics

-

Battery modules

-

Industrial inverters

4. Weight and Design Freedom

Carbon-based fillers are:

-

Much lighter than metal fillers

-

Effective at lower thickness

-

Compatible with flexible substrates

This enables:

-

Lightweight thermal solutions

-

Flexible electronics applications

-

Compact module designs

Electrical and Functional Trade-Offs

Traditional ceramic fillers are electrically insulating by nature. CNT–graphene systems, however, introduce electrical conductivity.

Design strategies include:

-

Controlled percolation to limit electrical pathways

-

Hybridization with insulating fillers

-

Application-specific conductivity tuning

In many applications (e.g., grounding, EMI shielding), this conductivity is a benefit rather than a drawback.

Manufacturing and Scale-Up Considerations

| Aspect | Traditional Fillers | CNT–Graphene TIMs |

|---|---|---|

| Mixing Energy | Moderate | High (dispersion critical) |

| Viscosity Control | Difficult at high loading | Easier at low loading |

| Equipment Compatibility | Mature | Adaptable |

| Cost per kg | Low | Higher |

| Cost per performance | Moderate | Optimized |

While CNT–graphene fillers may have higher unit cost, system-level cost is often lower due to reduced loading and improved reliability.

When to Choose CNT–Graphene TIMs

CNT–graphene TIMs are particularly suitable when:

-

Thin bond lines are required

-

Interface resistance dominates system performance

-

Weight and compliance matter

-

Long-term thermal stability is critical

When Traditional Fillers Still Make Sense

Traditional fillers remain viable when:

-

Electrical insulation is mandatory

-

Cost is the only driver

-

Performance requirements are moderate

-

Thickness and weight are not constrained

From Particle Packing to Network Engineering

The transition from traditional TIM fillers to CNT–graphene hybrid systems represents a shift in thermal design philosophy.

-

Traditional fillers rely on quantity

-

Hybrid carbon TIMs rely on connectivity

As thermal challenges grow more complex, engineered thermal networks—not just higher filler loading—will define next-generation TIM performance.