Why Many Graphene Projects Fail at Scale (and How to Avoid It)

Understanding the pitfalls between lab success and real-world application.

1. The promise vs. the reality

Graphene is a superstar in the lab:

-

Incredible conductivity

-

High surface area

-

Thermal and mechanical benefits

Yet, countless projects stumble when moving beyond small-scale demonstrations. Why?

Because scaling is not just “more of the same.”

It introduces a host of hidden challenges:

-

Material behavior changes with volume

-

Processing inconsistencies appear

-

Cost and reproducibility pressures emerge

The result: a promising material that fails to deliver in real applications.

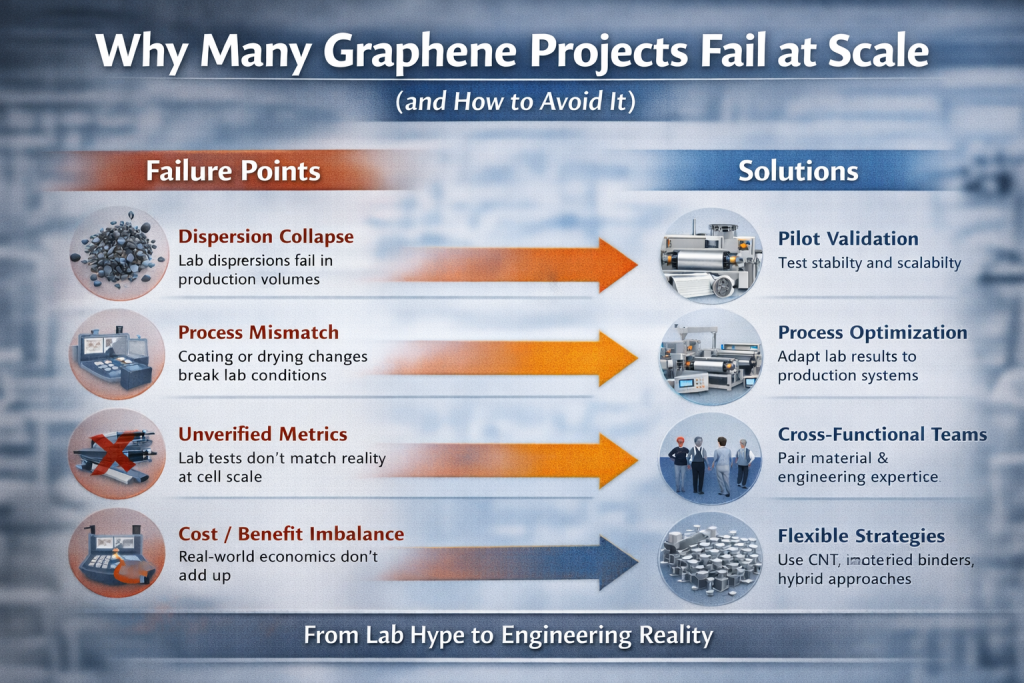

2. Common failure points at scale

1. Dispersion & consistency

Graphene is notoriously sensitive to agglomeration.

A small, well-dispersed batch in the lab might look perfect, but at 100+ liters, uniformity often collapses.

2. Process mismatch

Lab coating, drying, or mixing conditions rarely translate directly to pilot or production lines.

Line speeds, shear forces, and environmental factors all affect performance.

3. Material compatibility

Binders, solvents, and additives can behave differently at scale, leading to viscosity changes, sedimentation, or defects.

4. Unverified performance metrics

Lab tests often measure idealized performance.

At scale, minor defects, interface inconsistencies, or layer thickness variations can negate gains.

5. Cost vs. benefit

A material may work perfectly, but if it requires special processing or high-quality graphene for every gram, the economics may fail.

3. Why pilot validation is critical

Skipping pilot validation is the fastest path to failure.

Scaling up without testing at an intermediate scale ignores real-world variables.

Pilot validation allows you to:

-

Understand dispersion stability in production volumes

-

Adjust coating and drying processes for line compatibility

-

Test interaction with real binders, substrates, and cell chemistries

-

Measure realistic cost-performance trade-offs

Essentially, it transforms lab optimism into engineering reality.

4. Engineering reality check: the interface layer

Many failures occur not because graphene is bad, but because integration points are ignored:

-

Electrode slurries may behave unpredictably

-

Thermal interfaces may fail under repeated cycling

-

Cell assembly conditions may negate material improvements

The lesson: material performance alone is insufficient.

Integration, interface engineering, and process adaptation are just as important.

5. Strategies to avoid failure

1. Treat graphene as a system modifier

Focus on how it affects the full system — slurry, coating, cell, and module.

2. Invest in pilot-scale testing early

Small-batch successes are fragile; pilot-scale trials reveal real behavior before full investment.

3. Build cross-functional teams

Material scientists, process engineers, and battery developers must collaborate to catch hidden pitfalls.

4. Use realistic metrics

Evaluate improvements under conditions matching the final application, not just lab ideals.

5. Maintain flexibility

Sometimes the optimal solution is less graphene, or a hybrid approach with CNTs, coatings, or modified binders.

6. The hidden opportunity

While many projects fail, those who navigate these pitfalls gain:

-

Faster adoption of graphene innovations

-

Reduced technical risk

-

Improved cost-performance balance

-

Better industry credibility

The key: move beyond lab-scale hype and focus on engineering reality.

7. Positioning for success

Companies that thrive in graphene adoption are not just selling materials. They offer:

-

Material expertise

-

Pilot-scale validation

-

Engineering integration support

This middle layer — between lab research and full-scale production — is where the majority of real-world success happens.