Graphene in Anticorrosion Coatings: What Actually Matters

Separating hype from real-world impact in protective coatings.

1. Graphene isn’t magic — it’s strategic

Graphene gets attention for anticorrosion because of its:

-

High aspect ratio sheets

-

Impermeability to gases and liquids

-

Chemical stability

-

Electrical conductivity

But the question is not “Does graphene prevent corrosion?”

The question is:

“How do you use graphene to make coatings work reliably in real applications?”

2. Beyond the lab: why performance can differ

Many coatings show excellent barrier properties in small-scale lab tests:

-

Thin films

-

Ideal substrate surfaces

-

Controlled humidity and temperature

However, in real-world applications:

-

Substrate imperfections introduce pathways for moisture

-

Coating thickness is uneven

-

Environmental stresses (UV, temperature cycles, salt, chemicals) degrade performance

Graphene alone does not solve these issues. Its benefits appear only when well-integrated into the coating system.

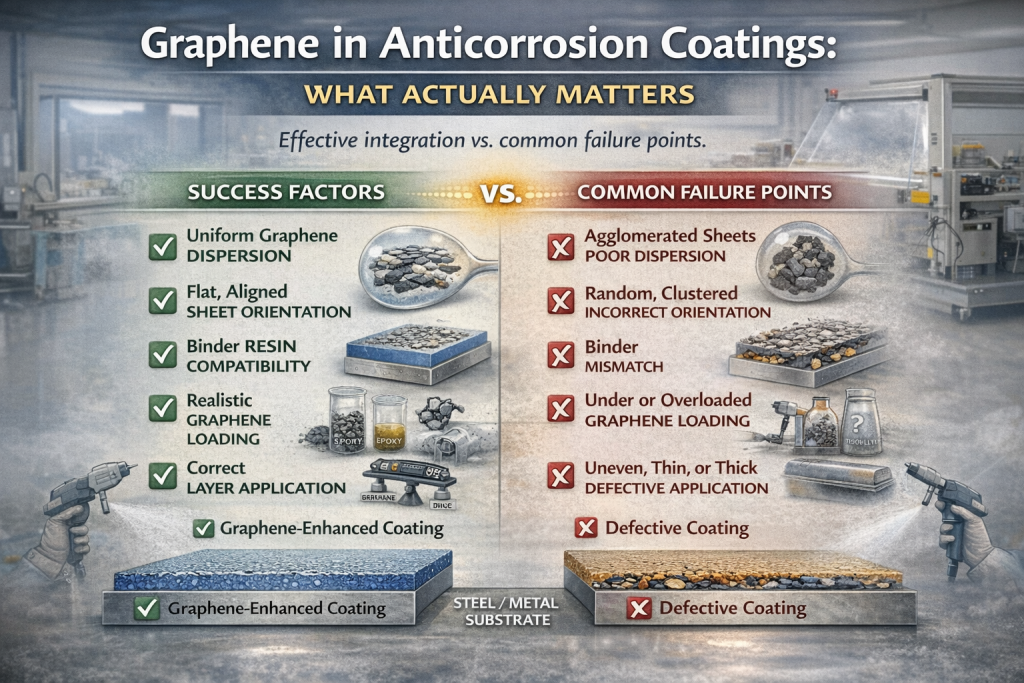

3. What actually matters in graphene anticorrosion coatings

1. Dispersion quality

Graphene sheets must be exfoliated and uniformly distributed.

Agglomerates create weak points for moisture and ions.

2. Sheet orientation & aspect ratio

Flat, high-aspect-ratio sheets aligned parallel to the substrate increase tortuosity, slowing corrosion pathways.

3. Compatibility with resin/binder systems

Graphene interacts differently with epoxies, polyurethanes, or acrylics.

Poor interaction leads to delamination or cracks.

4. Loading balance

Too little graphene → minimal effect

Too much graphene → aggregation, poor adhesion, higher cost

5. Layer thickness and application method

Spray, brush, or roll application affects final coating performance.

Even the best formulation fails if applied incorrectly.

4. Graphene as part of a system

Successful anticorrosion coatings use graphene as an enhancer, not the sole solution.

-

Barrier performance: increases tortuosity and reduces diffusion of oxygen/water

-

Mechanical reinforcement: reduces microcracks in the film

-

Electrical conductivity: can be leveraged in certain cathodic protection strategies

Integration with other fillers, inhibitors, and resins is crucial — graphene alone rarely solves corrosion completely.

5. Real-world validation is key

Laboratory tests like salt spray (ASTM B117) or electrochemical impedance spectroscopy (EIS) are necessary, but they must be complemented with field trials:

-

Coatings exposed to sunlight, humidity, salt, temperature cycles

-

Long-term adhesion and mechanical stability

-

Real substrate conditions (steel, aluminum, coated metals)

This ensures graphene’s benefits actually translate from lab to the industrial environment.

6. Takeaways for engineers and developers

-

Graphene is a system modifier, not a magic additive.

-

Focus on dispersion, orientation, and binder compatibility.

-

Conduct both lab tests and field trials before scaling.

-

Optimal loading and application method determine success.

-

Think of graphene as part of an integrated coating system — only then does it provide meaningful anticorrosion performance.

Graphene improves anticorrosion coatings when carefully formulated, applied, and validated.

Its real value comes from how it interacts with the coating system, not simply from being added to paint.