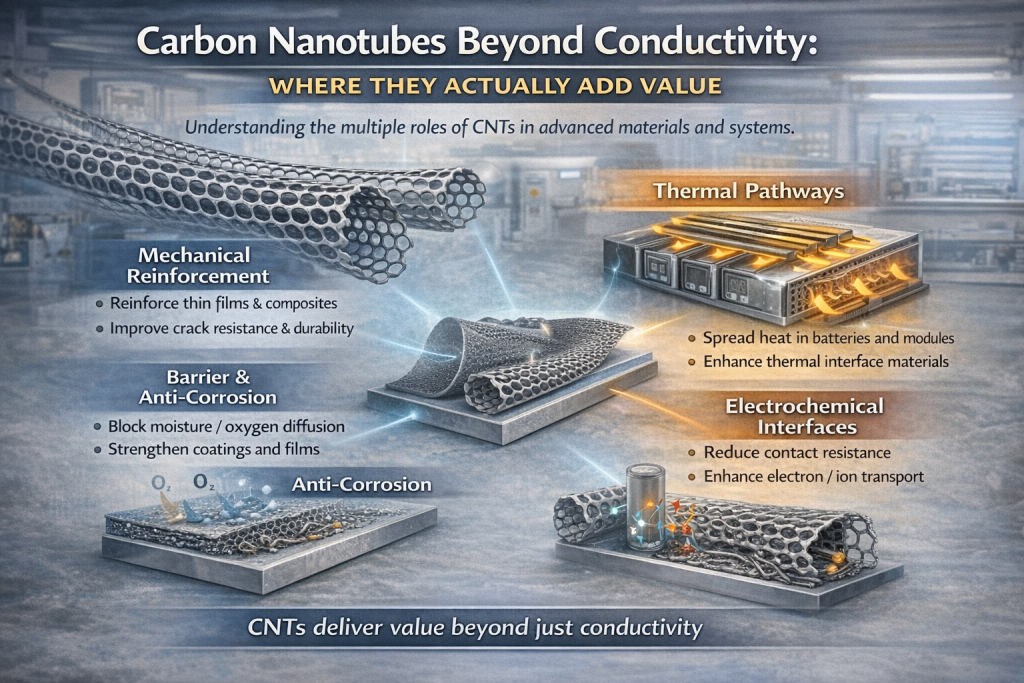

Carbon Nanotubes Beyond Conductivity: Where They Actually Add Value

Understanding the practical roles of CNTs in advanced materials and systems.

1. Conductivity is just the beginning

Carbon nanotubes (CNTs) are often promoted for their exceptional electrical conductivity.

But in most real-world applications, that is not their only value — and sometimes not the primary one.

CNTs also contribute to:

-

Mechanical reinforcement

High tensile strength and flexibility make composites tougher and more durable. -

Thermal management

High in-plane thermal conductivity can spread heat and prevent hot spots. -

Barrier enhancement

CNT networks can improve gas/liquid impermeability in coatings and films. -

Interfacial engineering

CNTs can enhance adhesion, reduce contact resistance, or improve electron/ion transport in electrodes.

Understanding these roles is crucial for applying CNTs efficiently — and avoiding overuse where they don’t add meaningful value.

2. Common misconceptions

1. CNT = “super conductor” in every composite

-

In polymers or coatings, the network must be continuous. Low loading or poor dispersion often limits conductivity gains.

2. More CNTs = better performance

-

Overloading can create agglomerates, reduce mechanical integrity, increase viscosity, and raise costs.

3. CNTs replace all other additives

-

CNTs are most effective as part of a hybrid system (with graphene, carbon black, or other fillers) for balanced performance.

3. Where CNTs really shine

A. Mechanical reinforcement in thin films and composites

-

Reduce cracking

-

Increase fracture toughness

-

Maintain flexibility under strain

B. Thermal pathways in energy devices

-

Spread heat in batteries, LEDs, and electronics

-

Enhance thermal interface materials (TIMs)

-

Reduce local overheating

C. Electrical & electrochemical interfaces

-

Improve conductivity where contact resistance matters

-

Enhance electron/ion transport in electrodes

-

Support current collection in thin, flexible layers

D. Barrier & anti-corrosion roles

-

Act as tortuous pathways for moisture and oxygen

-

Reinforce coatings to prevent microcrack propagation

4. Integration matters more than raw properties

CNT performance is highly sensitive to:

-

Dispersion & alignment

-

Matrix compatibility

-

Processing method (mixing, coating, extrusion, curing)

-

Concentration & aspect ratio balance

Poor integration often negates their advantages, while well-engineered systems maximize both mechanical, thermal, and electrical benefits.

5. Practical guidance

-

Target applications where multi-functional performance is needed

Don’t add CNTs just for conductivity — think mechanical + thermal + electrical synergy. -

Optimize loading & dispersion

Avoid agglomerates, balance viscosity, maintain processability. -

Combine with complementary materials

Hybrid fillers often outperform single-component CNT systems. -

Validate at scale

Lab tests are useful, but pilot-scale or field validation ensures the CNT network functions in the real system.

CNTs deliver real value when their multi-functional properties are harnessed strategically.

Understanding the where, how, and why allows engineers to avoid wasted material, unnecessary cost, and missed performance opportunities.