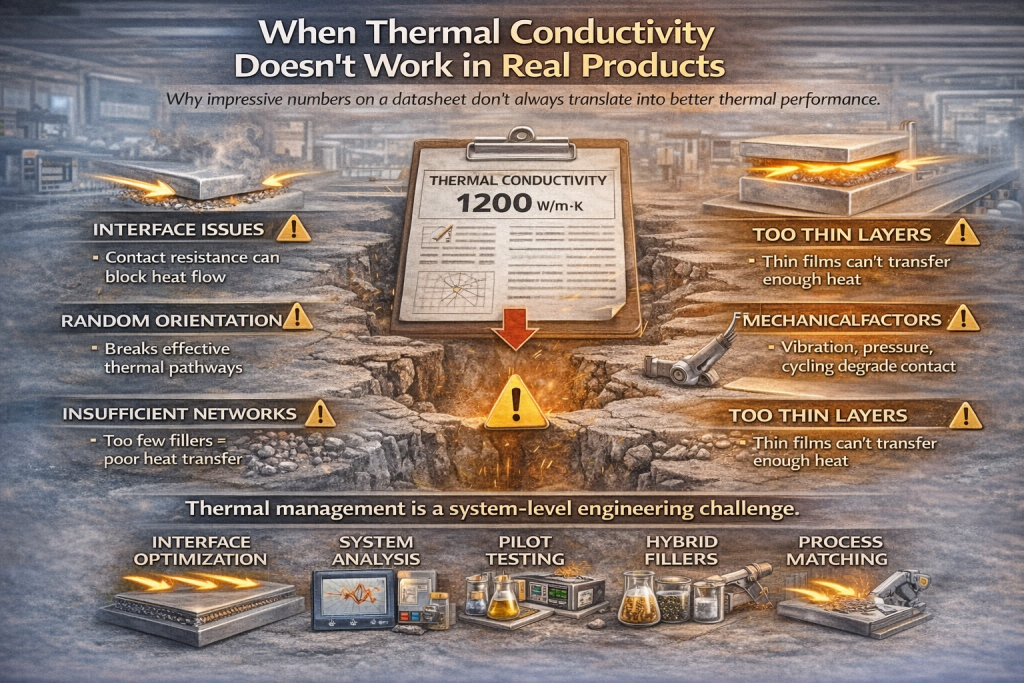

When High Thermal Conductivity Doesn’t Work in Real Products

Why impressive numbers on a datasheet don’t always translate into better thermal performance.

The assumption that misleads many projects

In thermal management discussions, one metric often dominates:

Thermal conductivity (W/m·K).

If a material shows higher conductivity in the lab, it should improve heat dissipation in the final product — at least in theory.

Yet in real systems, engineers often discover:

-

Temperatures barely improve

-

Hot spots remain

-

Reliability issues persist

-

Cost rises without clear benefit

The problem is not the material itself.

The problem is how heat actually moves through systems, not isolated materials.

Materials don’t manage heat. Systems do.

A filler or coating can have extremely high intrinsic thermal conductivity, but that alone does not guarantee performance.

Real thermal performance depends on:

-

Interfaces

-

Contact resistance

-

Geometry

-

Thickness

-

Orientation

-

Processing

-

Assembly pressure

-

Air gaps

A material with 1000 W/m·K conductivity cannot overcome poor interface contact or design limitations.

Where high thermal conductivity fails in practice

1. Interface resistance dominates

Heat often encounters its biggest barrier at interfaces:

-

Filler → binder

-

Coating → substrate

-

TIM → device surface

If contact is poor, even highly conductive materials cannot transfer heat efficiently.

In many systems, interface resistance outweighs bulk conductivity.

2. Orientation matters more than intrinsic values

Some advanced materials conduct heat very well in one direction but poorly in another.

If they are randomly oriented during processing:

-

Thermal pathways break

-

Heat spreading becomes uneven

-

Performance drops below expectations

A material with excellent in-plane conductivity may perform poorly if vertical heat transfer is required.

3. Insufficient filler networks

High conductivity fillers must form continuous pathways.

If loading is too low or dispersion is uneven:

-

Heat cannot travel efficiently

-

Isolated particles contribute little

-

Performance gains remain minimal

In some cases, increasing loading helps — but then viscosity, weight, and cost become issues.

4. Thickness limitations

Thin coatings or layers may not allow enough filler-to-filler contact.

Even with high conductivity materials:

-

Thin films limit heat transfer

-

Thermal spreading may improve

-

Through-thickness conduction may not

Design constraints often prevent using enough material to achieve theoretical performance.

5. Mechanical and assembly realities

Thermal systems rarely exist in static lab conditions.

Real products face:

-

Vibration

-

Thermal cycling

-

Expansion mismatch

-

Pressure changes

-

Surface roughness

These factors influence contact quality and long-term thermal stability.

A material that performs well in controlled tests may degrade in real operation.

When high conductivity still helps

High thermal conductivity materials do provide real benefits when:

-

Interface contact is optimized

-

Filler networks are continuous

-

Orientation is controlled

-

Layer thickness is appropriate

-

Mechanical stability is maintained

In these cases, they improve:

-

Heat spreading

-

Hot spot reduction

-

Temperature uniformity

-

Long-term reliability

But these improvements come from system integration, not material substitution alone.

The engineering perspective

Instead of asking:

“Which material has the highest conductivity?”

A more useful question is:

“How does heat move through this product?”

That includes:

-

Heat source location

-

Path to heat sink

-

Contact interfaces

-

Mechanical constraints

-

Manufacturing methods

Thermal management is a design problem first, and a materials problem second.

Bridging the gap between material and product

Successful thermal projects usually include:

-

Early system-level analysis

-

Pilot-scale testing

-

Interface optimization

-

Hybrid filler strategies

-

Process-compatible formulations

When materials are evaluated within the context of real assembly and operation, performance predictions become far more accurate.

A quieter but more useful takeaway

High thermal conductivity is valuable.

But it is not a guarantee.

In real products, performance comes from:

-

Material selection

-

Interface design

-

Processing

-

Validation

-

Engineering integration

When these elements align, thermal materials deliver meaningful improvements.