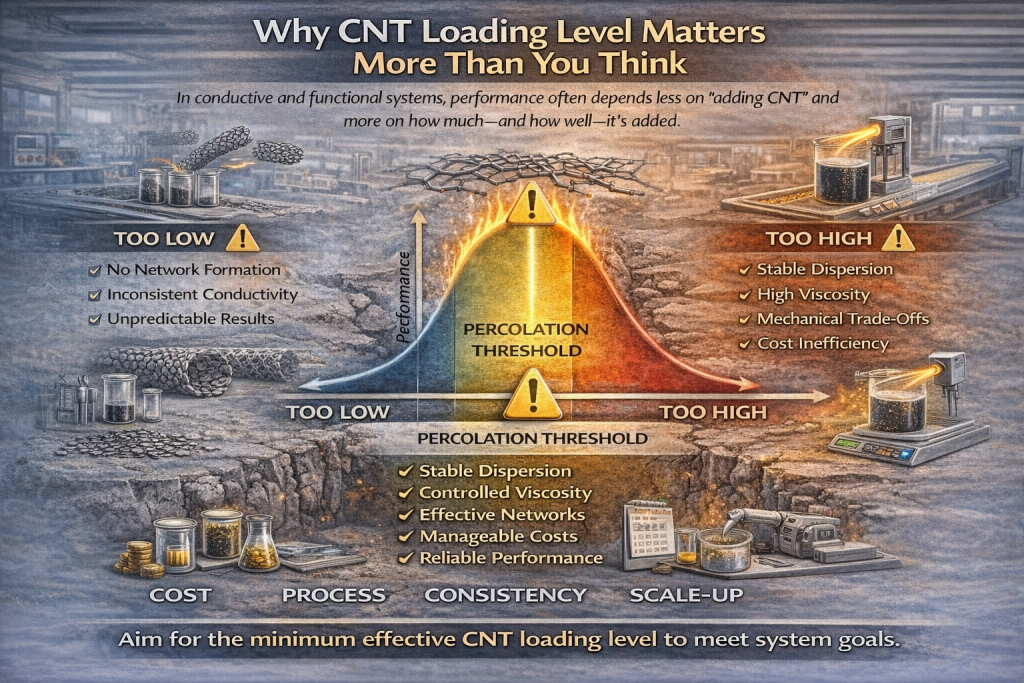

Why CNT Loading Level Matters More Than You Think

In conductive and functional systems, performance often depends less on “adding CNT” and more on how much—and how well—it’s added.

The common shortcut in material discussions

In many projects, once carbon nanotubes (CNTs) are introduced, the assumption is:

“If conductivity or reinforcement improves, just add more.”

But CNT systems rarely behave linearly.

After a certain point, increasing loading can reduce performance, complicate processing, and raise costs—without meaningful gains.

CNT loading is not just a formulation detail.

It is often the factor that determines whether a project reaches production.

The concept of percolation

CNTs form conductive networks through a phenomenon called percolation.

At low loading:

-

CNTs are isolated

-

Conductivity remains low

-

Mechanical effects are minimal

At a critical loading threshold:

-

CNTs connect into networks

-

Conductivity increases rapidly

-

System performance changes significantly

Beyond that threshold:

-

Gains slow down

-

Agglomeration risk rises

-

Processability declines

This means performance does not scale with loading in a straight line.

When loading is too low

If CNT loading sits below the percolation threshold:

-

Networks don’t form

-

Conductivity improvements are inconsistent

-

Performance varies batch to batch

-

Customers may see unstable results

This often happens when teams try to minimize cost without validating functional thresholds.

When loading is too high

Adding more CNT than necessary introduces new problems:

1. Dispersion challenges

Higher loading increases the chance of agglomeration.

Clusters reduce effective conductivity and create weak points.

2. Viscosity increase

CNTs dramatically affect rheology.

Excess loading can make coatings or composites difficult to process.

3. Mechanical trade-offs

Too many CNTs can make systems brittle or reduce adhesion.

4. Cost inefficiency

Beyond optimal loading, performance gains become marginal while costs continue rising.

The narrow optimal window

Most CNT systems have a relatively narrow loading window where:

-

Networks form effectively

-

Dispersion remains stable

-

Processing is manageable

-

Costs stay reasonable

-

Performance gains are meaningful

Finding this window requires:

-

Realistic dispersion methods

-

Process-compatible testing

-

Pilot-scale validation

Lab-scale optimization alone is rarely enough.

Different applications, different targets

Optimal CNT loading varies by application.

Conductive coatings

Need stable surface conductivity without excessive viscosity.

Battery electrodes

Require network formation with minimal impact on energy density.

Composites

Balance mechanical reinforcement with processability.

Thermal systems

Use CNTs for network enhancement rather than bulk conduction.

Each case has its own threshold and limits.

The scaling factor

A formulation that works at small scale may not behave the same in production.

At larger scale:

-

Mixing energy changes

-

Shear conditions differ

-

Dispersion stability shifts

-

Equipment influences network formation

This can shift the effective percolation threshold.

That’s why CNT loading must be validated under realistic conditions.

Why customers care

From a customer’s perspective, loading level affects:

-

Cost per unit

-

Process stability

-

Batch consistency

-

Long-term reliability

-

Integration with existing systems

A material that works only at impractical loading levels rarely moves forward.

A practical mindset

Instead of asking:

“How much CNT can we add?”

A more useful question is:

“What is the minimum loading needed to achieve stable performance?”

This approach:

-

Reduces cost

-

Improves consistency

-

Maintains processability

-

Supports scale-up

Beyond numbers on a formulation sheet

CNT loading is not just a percentage.

It is a balance between:

-

Network formation

-

Dispersion stability

-

Processing constraints

-

Cost

-

System performance

When optimized carefully, CNT delivers strong functional benefits.

When misjudged, it becomes expensive filler with limited impact.

A quieter takeaway

Many CNT projects do not fail because CNT doesn’t work.

They stall because loading levels were never properly optimized for real production.

When loading is right—and validated at scale—CNT becomes a reliable engineering tool rather than an experimental additive.