A New Carbon Material—8 Times Stronger Than Graphene!

In recent years, monolayer graphene and other two-dimensional (2D) materials have attracted widespread attention due to their excellent mechanical, electrical, and thermal properties. However, their brittleness has limited their practical applications, as they are prone to fracture under external forces, especially when subjected to impact or bending.

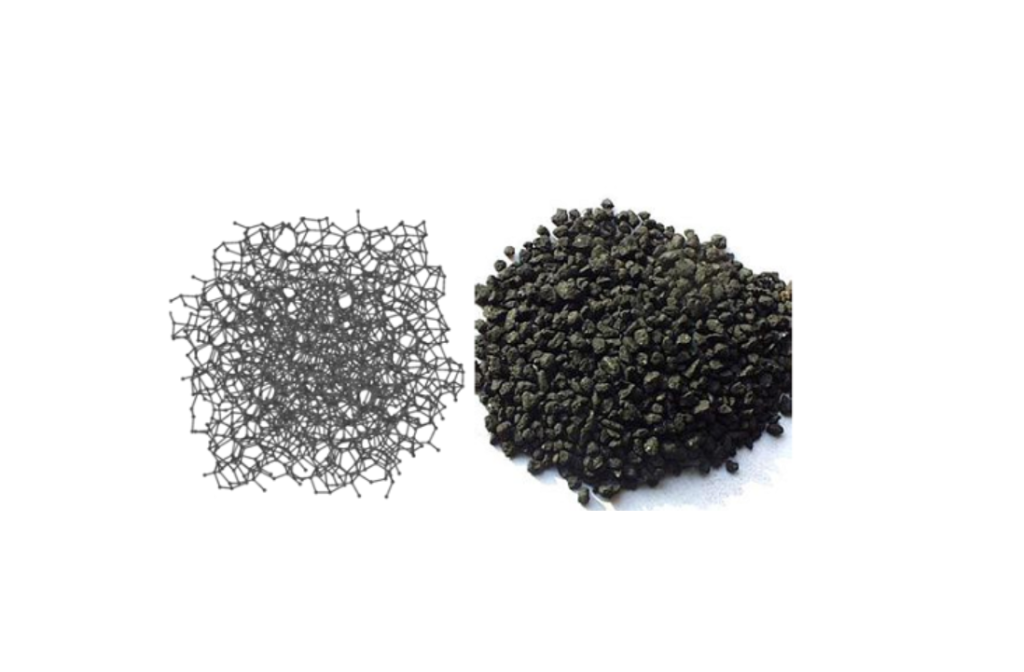

Monolayer Amorphous Carbon (MAC) nanocomposite materials, composed of an amorphous carbon matrix with embedded nanocrystalline phases, exhibit superior mechanical properties compared to traditional 2D materials. By rationally designing the ratio of crystalline and amorphous phases, MAC materials not only enhance crack resistance but also significantly improve energy absorption and fracture toughness.

Synthesized through Laser-Assisted Chemical Vapor Deposition (LCVD), MAC demonstrates greater crack resistance than monolayer graphene. In situ tensile testing reveals that the fracture energy release rate of MAC samples is eight times that of monolayer graphene. This breakthrough indicates that MAC materials can more effectively resist crack propagation and absorb more energy when cracks occur, preventing brittle fracture. Additionally, during tensile testing, MAC samples exhibit significant crack deflection, branching, and bridging—phenomena absent in pure graphene.

Key Mechanisms Enhancing Fracture Toughness

The crack deflection and branching phenomena in MAC materials play a crucial role in enhancing their fracture toughness. When a crack encounters a crystalline domain embedded in the matrix, its propagation path is forced to deflect, consuming more energy during crack expansion. This not only effectively reduces crack propagation speed but also prevents further crack extension, thereby improving the material’s overall fracture resistance.

As 2D materials continue to advance in modern technology, MAC is emerging as a strong contender for the next generation of high-performance materials, particularly in applications such as flexible electronics, energy storage, sensors, and aerospace.

Applications of MAC

• Flexible Electronics

Flexible electronics, characterized by their lightweight, bendability, and stretchability, have become a major development direction in the electronics industry, enabling smart wearable devices, flexible sensors, and foldable displays. However, mechanical strength and crack resistance remain significant challenges. MAC’s superior crack resistance and energy absorption capabilities can effectively enhance the durability and reliability of flexible electronic devices under repeated bending, stretching, and compression. For example, in wearable devices, MAC can be used as an encapsulation material for flexible sensors, preventing damage caused by frequent movement.

• Energy Storage & Battery Technology

In energy storage, particularly in lithium-ion batteries and supercapacitors, material strength and toughness are crucial for the battery’s cycle life and stability. MAC’s structural design not only enhances mechanical strength, preventing cracks caused by external forces or repeated charge-discharge cycles, but also improves cycle stability under high loads. Additionally, MAC’s intrinsic electrical conductivity makes it highly valuable in energy storage devices like supercapacitors, helping to improve charging/discharging efficiency and energy density.

• Sensors & Smart Systems

Thanks to its excellent mechanical properties and tunable electrical characteristics, MAC shows great potential in the smart sensor field. Its high toughness ensures stable performance under high stress and complex environments, preventing performance degradation due to external impact or physical changes. Furthermore, its electrical properties can be adjusted as needed to manufacture highly sensitive sensors for applications in smartwatches, health monitoring devices, and environmental sensors.

• Aerospace & High-Strength Composites

In aerospace, high strength, toughness, and lightweight properties are critical design factors. Balancing these requirements has long been a technological challenge. With its exceptional fracture toughness and strength, MAC can play a crucial role in spacecraft construction, particularly in outer shells and protective layers. It can effectively withstand extreme environments, including high temperatures, high pressure, and micro-collisions, ensuring spacecraft stability during atmospheric entry and extended space missions. Additionally, as a 2D composite material, MAC’s tunability and multifunctionality offer new possibilities for future aerospace material innovations.

Conclusion

As an emerging 2D material, MAC demonstrates unique application potential across multiple fields. With ongoing research, its production processes and application technologies will continue to mature, paving the way for its widespread adoption and contributing to the development of next-generation high-performance materials.