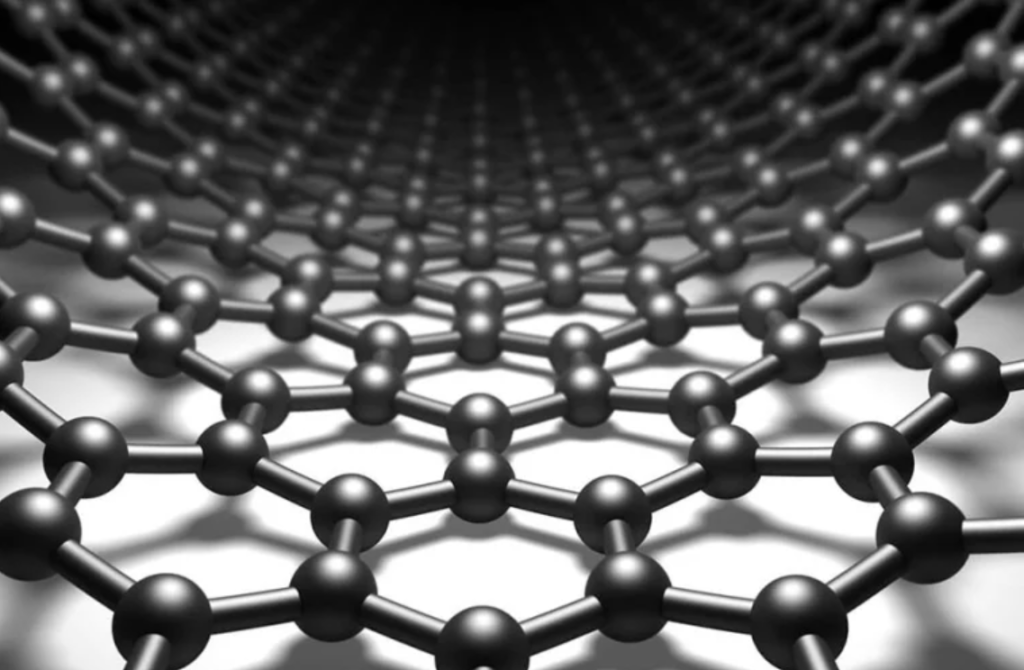

Application Characteristics of Graphene in Environmentally Friendly Water-Based Coatings

Water-based coatings, often preferred in environmentally friendly applications, use water as a solvent, reducing or eliminating the need for volatile organic compounds (VOCs). Graphene has shown great promise in improving the performance of these coatings, enhancing their mechanical, chemical, and functional properties. The incorporation of graphene into water-based coatings provides a unique set of advantages, including improved strength, corrosion resistance, and environmental stability. Below are the key characteristics and applications of graphene in environmentally friendly water-based coatings.

1. Enhanced Mechanical Properties

Graphene can significantly improve the mechanical properties of water-based coatings, making them more durable and resilient.

-

Mechanism: Graphene’s exceptional strength, flexibility, and stiffness reinforce the polymer matrix in water-based coatings. By integrating graphene into the polymer structure, it can effectively increase the tensile strength, elasticity, and impact resistance of the coating, thus improving its overall mechanical performance.

- Example: In industrial coatings, graphene is used to enhance the scratch resistance and durability of water-based coatings, ensuring that the coating maintains its integrity even under abrasive conditions.

-

Effect: The improved mechanical properties of water-based coatings lead to longer-lasting protective layers, especially in harsh environments like automotive, construction, and electronics.

2. Improved Corrosion Resistance

One of the most important characteristics of water-based coatings is their ability to protect substrates (such as metals and concrete) from corrosion. Graphene significantly enhances this protective function.

-

Mechanism: Graphene’s unique structure and high surface area form an effective barrier, reducing the permeability of water and oxygen to the substrate. The graphene sheets, dispersed within the polymer matrix, create a tortuous path for corrosive agents, which hinders the penetration of water and corrosive chemicals.

- Example: In marine coatings, graphene-infused water-based coatings are used to protect ships, pipelines, and offshore platforms from saltwater corrosion, extending the lifespan of these structures and reducing maintenance costs.

-

Effect: The incorporation of graphene enhances the corrosion resistance of water-based coatings, making them ideal for use in harsh, corrosive environments, such as coastal areas, industrial facilities, and outdoor infrastructure.

3. Enhanced Thermal Stability and Conductivity

Graphene improves the thermal stability and thermal conductivity of water-based coatings, making them more effective in heat management.

-

Mechanism: Graphene has excellent thermal conductivity, which can be transferred to the water-based coatings. This enables the coating to dissipate heat more efficiently and prevent the buildup of heat on the substrate, which can otherwise lead to degradation or failure of the coating.

- Example: In construction applications, graphene-based waterborne coatings can be applied to buildings and roofs to manage temperature regulation, reducing energy consumption for cooling or heating.

-

Effect: The enhanced thermal properties provide better protection against temperature fluctuations and improve the long-term durability of the coating, particularly in industries where heat resistance is crucial (e.g., electronics, automotive, and construction).

4. UV Resistance and Durability

Graphene can improve the UV resistance and durability of water-based coatings, making them more suitable for outdoor applications where UV radiation can degrade traditional coatings.

-

Mechanism: Graphene acts as a UV-blocking agent, preventing the degradation of the polymer matrix when exposed to sunlight. It absorbs UV radiation and minimizes the formation of free radicals, which can otherwise break down the coating material over time.

- Example: Water-based coatings used for outdoor signage, façades, or vehicle exteriors can benefit from graphene’s UV resistance, maintaining their appearance and protective properties for extended periods, even under intense sunlight.

-

Effect: Graphene-infused water-based coatings provide enhanced protection against UV degradation, improving the coating’s longevity and maintaining its appearance and functionality over time.

5. Enhanced Barrier Properties

Graphene’s excellent barrier properties are one of the most significant benefits of incorporating it into water-based coatings.

-

Mechanism: The graphene sheets, when incorporated into the coating, create a dense network that acts as a physical barrier to moisture, air, and other environmental contaminants. This prevents the penetration of these substances into the substrate, reducing the risk of damage and improving the overall performance of the coating.

- Example: In food packaging, water-based coatings enhanced with graphene can provide an additional protective layer, preventing the penetration of gases, moisture, or oils, thereby extending the shelf life of the product.

-

Effect: The barrier properties of graphene-based water coatings make them ideal for use in packaging, corrosion prevention, and other applications that require an effective protective shield against environmental exposure.

6. Eco-Friendly and Low Toxicity

As water-based coatings are already environmentally friendly due to their low VOC content, adding graphene enhances their eco-friendliness by improving the overall durability and longevity of the coating, reducing the need for frequent reapplication.

-

Mechanism: Graphene is an environmentally benign material, and its addition to water-based coatings does not introduce harmful chemicals or VOCs into the environment. This makes the overall product safer and more sustainable.

- Example: Graphene-based waterborne paints used in interior walls or furniture contribute to healthier indoor air quality, as they are free from harmful solvents and emissions, promoting a safer environment.

-

Effect: The addition of graphene to water-based coatings increases the sustainability of the coating system, reducing the environmental impact and making it more suitable for eco-conscious applications.

7. Self-Healing Properties (Potential)

Graphene, in combination with other materials, has the potential to contribute to self-healing properties in water-based coatings.

-

Mechanism: The combination of graphene with certain polymers or microcapsules can enable the development of coatings with self-healing properties. When the coating is damaged, the graphene network can facilitate the healing process by supporting the reformation of the coating matrix.

- Example: In automotive applications, graphene-based waterborne coatings could be developed to self-heal small scratches or cracks that may occur on the car’s exterior, reducing maintenance needs and prolonging the lifespan of the coating.

-

Effect: The development of self-healing graphene-based coatings will significantly reduce maintenance costs and extend the durability of coatings in high-wear applications.

8. Anti-Bacterial and Anti-Fungal Properties (Potential)

Graphene’s antibacterial and antifungal properties are another benefit for water-based coatings, especially in environments where hygiene is crucial.

-

Mechanism: Graphene has been shown to exhibit antibacterial and antifungal properties due to its ability to disrupt microbial cell membranes. This can be leveraged in waterborne coatings to provide enhanced protection against microbial growth on painted surfaces.

- Example: In healthcare facilities or food processing environments, graphene-enhanced waterborne coatings can be used on walls, floors, or equipment to prevent the growth of bacteria and fungi, ensuring cleaner and safer environments.

-

Effect: The addition of graphene provides antimicrobial properties, making the coatings ideal for use in environments where hygiene and cleanliness are critical, further increasing the performance of water-based coatings.

Applications of Graphene in Water-Based Coatings

- Automotive: Graphene-based waterborne coatings improve the durability and appearance of vehicle exteriors, protecting them from UV degradation, corrosion, and environmental stress.

- Construction: Graphene waterborne coatings are used in building exteriors and interiors to protect surfaces from weathering, UV damage, and corrosion while providing a longer-lasting finish.

- Electronics: Water-based coatings infused with graphene can provide better corrosion resistance and improved thermal and electrical conductivity for electronic components.

- Marine and Offshore: Graphene enhances the corrosion resistance of water-based coatings used on ships, offshore platforms, and pipelines exposed to saltwater environments.

- Food Packaging: Graphene-infused waterborne coatings provide improved barrier properties for food packaging, protecting contents from external contamination and extending shelf life.

Conclusion

The application of graphene in environmentally friendly water-based coatings significantly improves their mechanical properties, corrosion resistance, UV stability, and barrier function while enhancing their eco-friendliness. By leveraging graphene’s unique characteristics, these coatings can meet the increasing demand for sustainable, high-performance materials across a variety of industries, including automotive, construction, electronics, and food packaging. The incorporation of graphene into waterborne coatings is not only a step towards improving their functionality but also towards promoting a greener and more sustainable approach to coating technology.