Applications of Single-Walled Carbon Nanotubes (SWCNTs) in Aerospace and High-Strength Composite Materials

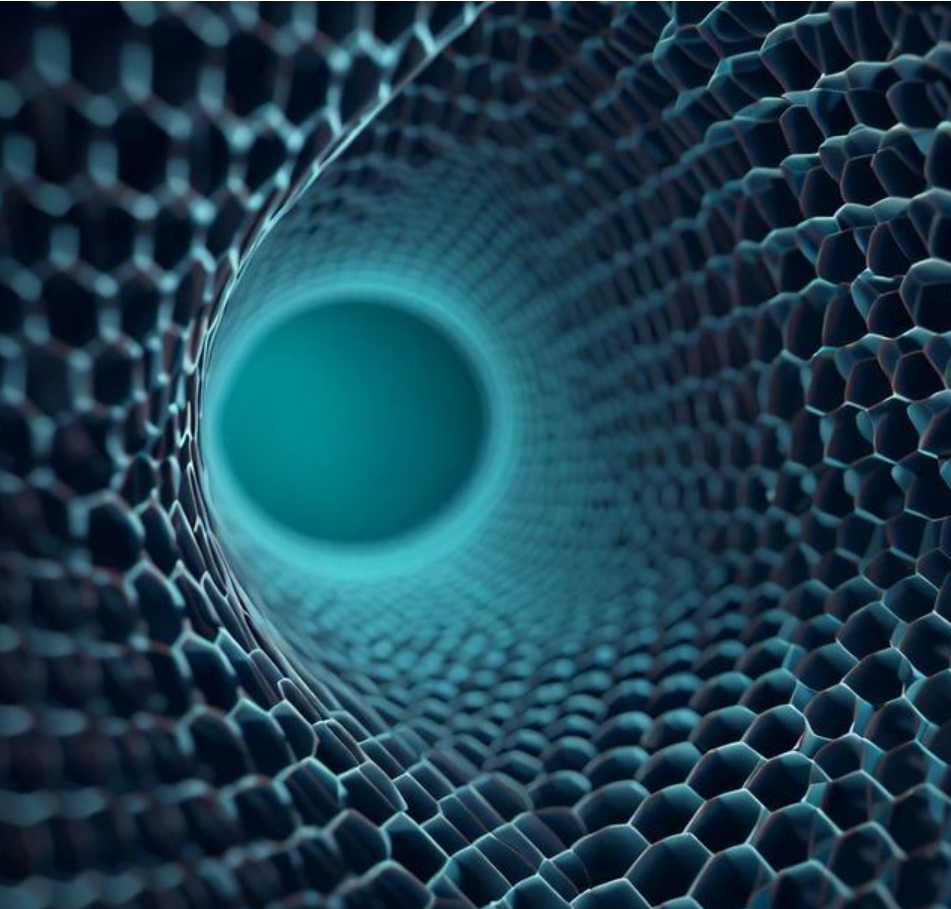

Single-walled carbon nanotubes (SWCNTs) are redefining the boundaries of material science, particularly in aerospace and high-strength composite materials. With their remarkable mechanical, thermal, and electrical properties, SWCNTs offer transformative solutions for reducing weight, enhancing structural strength, and improving durability in demanding environments. This article delves into the ways SWCNTs are revolutionizing composite materials and highlights real-world applications in the aerospace industry.

1. Advantages of SWCNTs in Composite Materials

Composite materials combine two or more components to achieve superior properties compared to individual materials. The incorporation of SWCNTs as a reinforcing agent has unlocked new possibilities in developing high-performance composites.

1.1. Exceptional Strength-to-Weight Ratio

SWCNTs possess a tensile strength of approximately 100–150 GPa, making them one of the strongest materials known.

- Impact on Composites: Adding even a small fraction (e.g., <1 wt%) of SWCNTs significantly enhances the strength of polymers and resins while keeping the material lightweight.

- Use Case: Lightweight components that retain structural integrity under extreme stress, such as aircraft fuselages and turbine blades.

1.2. Enhanced Thermal Conductivity

With thermal conductivity reaching up to 3,000 W/m·K, SWCNTs effectively dissipate heat.

- Impact on Aerospace: Prevents thermal degradation in high-temperature environments, such as spacecraft re-entry or supersonic flight.

1.3. Superior Electrical Conductivity

SWCNTs have exceptional electrical conductivity, making them ideal for creating composites with improved conductivity.

- Applications: Used in aerospace components for lightning strike protection and electromagnetic interference (EMI) shielding.

1.4. Resistance to Environmental Degradation

SWCNTs enhance the durability of composites by improving resistance to corrosion, UV radiation, and chemical exposure.

- Impact on Aerospace: Extends the lifespan of critical components exposed to harsh environmental conditions.

2. Applications in High-Strength Composite Materials

SWCNT-reinforced composites are finding widespread applications in industries that demand robust and lightweight materials.

2.1. Aircraft Structures

- Airframes and Fuselages: SWCNT composites reduce weight while maintaining the strength and rigidity required for structural components.

- Landing Gear: Incorporating SWCNTs into high-stress areas improves durability without adding excessive weight.

- Wings and Control Surfaces: SWCNTs enhance flexibility and strength, enabling better performance under aerodynamic forces.

2.2. Spacecraft and Satellites

- Thermal Protection Systems: SWCNT composites are used to develop lightweight, heat-resistant shields for spacecraft.

- Payload Components: SWCNTs reduce weight and improve structural integrity, ensuring payload safety during launches.

- Solar Panels: SWCNTs are integrated into flexible and durable materials for satellite solar panels, ensuring longevity and resilience in orbit.

2.3. Rotorcraft and Drones

- Rotor Blades: Lightweight SWCNT composites reduce fuel consumption and improve maneuverability for helicopters and drones.

- Drone Frames: SWCNTs provide high strength-to-weight ratios, allowing drones to carry heavier payloads or achieve longer flight times.

2.4. Rocket and Propulsion Systems

- Rocket Nozzles: SWCNT composites withstand extreme temperatures and stresses during launches and re-entry.

- Fuel Tanks: SWCNTs improve the strength and leak resistance of cryogenic fuel storage tanks.

3. Real-World Aerospace Applications

3.1. Boeing and Airbus

- Both companies are exploring SWCNT-reinforced composites for lightweight airframes, aiming to improve fuel efficiency and reduce emissions.

3.2. NASA and SpaceX

- NASA is researching SWCNT-based materials for spacecraft capable of withstanding extreme space conditions, such as radiation and temperature fluctuations.

- SpaceX is testing advanced composites for rocket bodies and payload fairings, leveraging SWCNTs to minimize weight without compromising performance.

3.3. Satellite Manufacturers

- Companies like OneWeb and Maxar Technologies are integrating SWCNT composites into satellite structures to extend their operational lifespan in orbit.

4. Challenges in Adoption

Despite their potential, SWCNTs face several challenges that limit their widespread adoption in aerospace and composite applications.

4.1. Production and Cost

- Challenge: High-quality SWCNTs suitable for aerospace applications are expensive and difficult to produce at scale.

- Solution: Advances in chemical vapor deposition (CVD) and purification methods are gradually reducing costs and improving scalability.

4.2. Uniform Dispersion in Matrices

- Challenge: Achieving uniform dispersion of SWCNTs in composite matrices is technically challenging and affects material performance.

- Solution: Surface functionalization and the use of surfactants are improving compatibility with polymers and resins.

4.3. Regulatory and Certification Hurdles

- Challenge: Aerospace materials undergo rigorous testing and certification, slowing the adoption of novel materials like SWCNTs.

- Solution: Collaborative efforts between aerospace companies, material scientists, and regulatory agencies are addressing safety and performance standards.

5. Future Prospects

The future of SWCNTs in aerospace and high-strength composites looks promising as technological advancements address current limitations:

5.1. Next-Generation Aircraft

SWCNT-reinforced composites will play a pivotal role in developing next-generation commercial and military aircraft, prioritizing fuel efficiency and sustainability.

5.2. Advanced Space Missions

Space exploration will benefit from lightweight and durable SWCNT composites, enabling the construction of spacecraft for deep-space missions.

5.3. Integration with Emerging Technologies

- 3D Printing: SWCNTs are being explored for additive manufacturing, enabling the rapid production of complex aerospace components.

- Smart Materials: SWCNTs are being integrated into composites to create materials with self-healing and adaptive properties.

6. Conclusion

Single-walled carbon nanotubes have the potential to transform the aerospace and high-strength composite materials industries by offering unparalleled mechanical, thermal, and electrical properties. While challenges remain in production scalability, dispersion, and certification, ongoing research and development are rapidly advancing the field.

As SWCNT technologies mature, their adoption in aerospace and other high-performance industries is expected to accelerate, heralding a new era of materials science innovation that will redefine what is possible in engineering and design.