Breakthrough in Porous Graphene Membranes!

In the world of smart electronic devices, pressure sensors play a crucial role, acting as a bridge between the physical and digital worlds. From aerospace to human-machine interaction, from motion detection to structural health monitoring, the applications of pressure sensors are everywhere. The ideal pressure sensor needs to be highly sensitive across a wide pressure range, covering everything from tactile touch to low and medium pressures, as well as high and even ultra-high pressures. However, traditional piezoresistive pressure sensors based on graphene oxide (GO) face limitations due to the point-to-point contact mechanism between nanosheets, resulting in low modulus and difficulties in high and ultra-high pressure sensing.

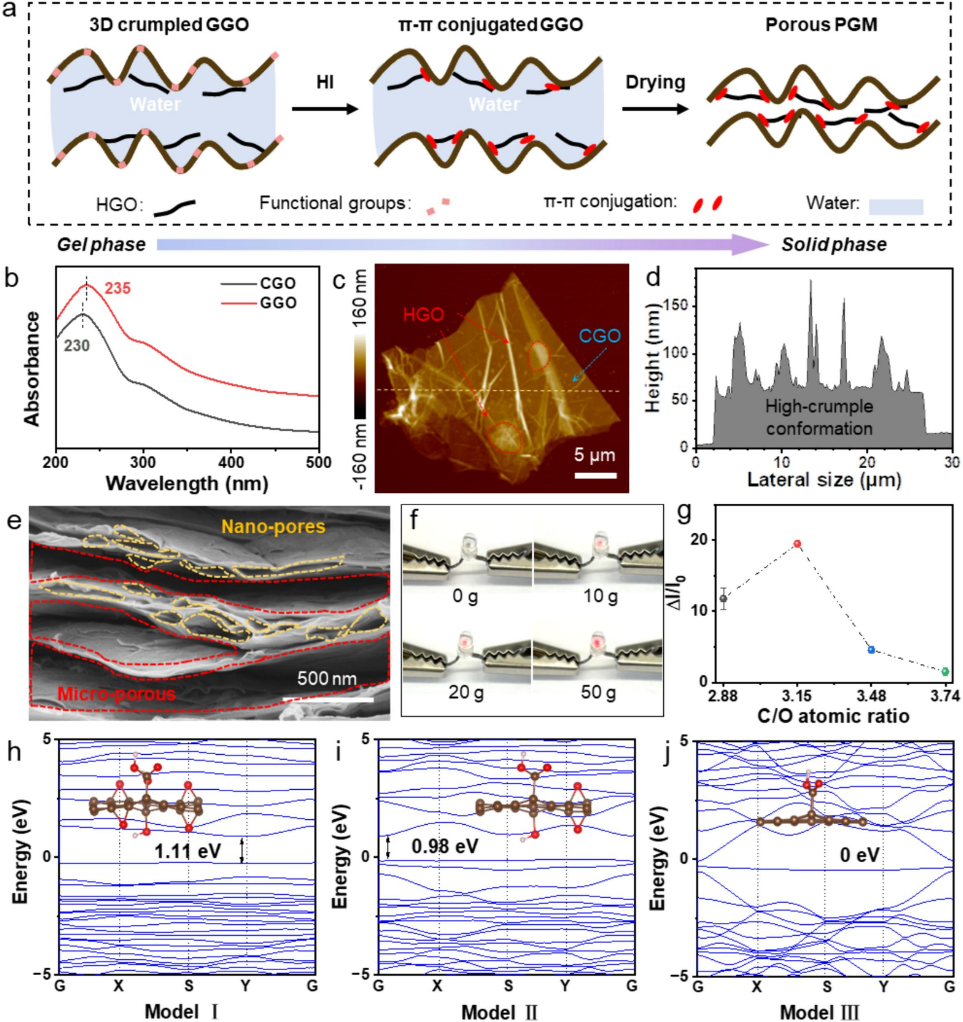

To address this issue, a research team led by Professors Jia Xiaolong and Yang Xiaoping from the College of Materials Science and Engineering at Beijing University of Chemical Technology has published an innovative study in the Chemical Engineering Journal. The paper introduces a new method for constructing hierarchically porous graphene membranes (PGM) based on conformational interlocking. Through π-π conjugated interactions, the study locks the 3D crumpled conformation of graphene oxide (GO) nanosheets, creating flexible graphene membranes (PGM) with a hierarchically porous structure. This hierarchical pore structure enables a two-step deformation mechanism, resulting in sensitive responses across ultra-high pressure ranges.

Figure 1: Structural modulation from 3D crumpled GO nanosheets to hierarchically porous PGM

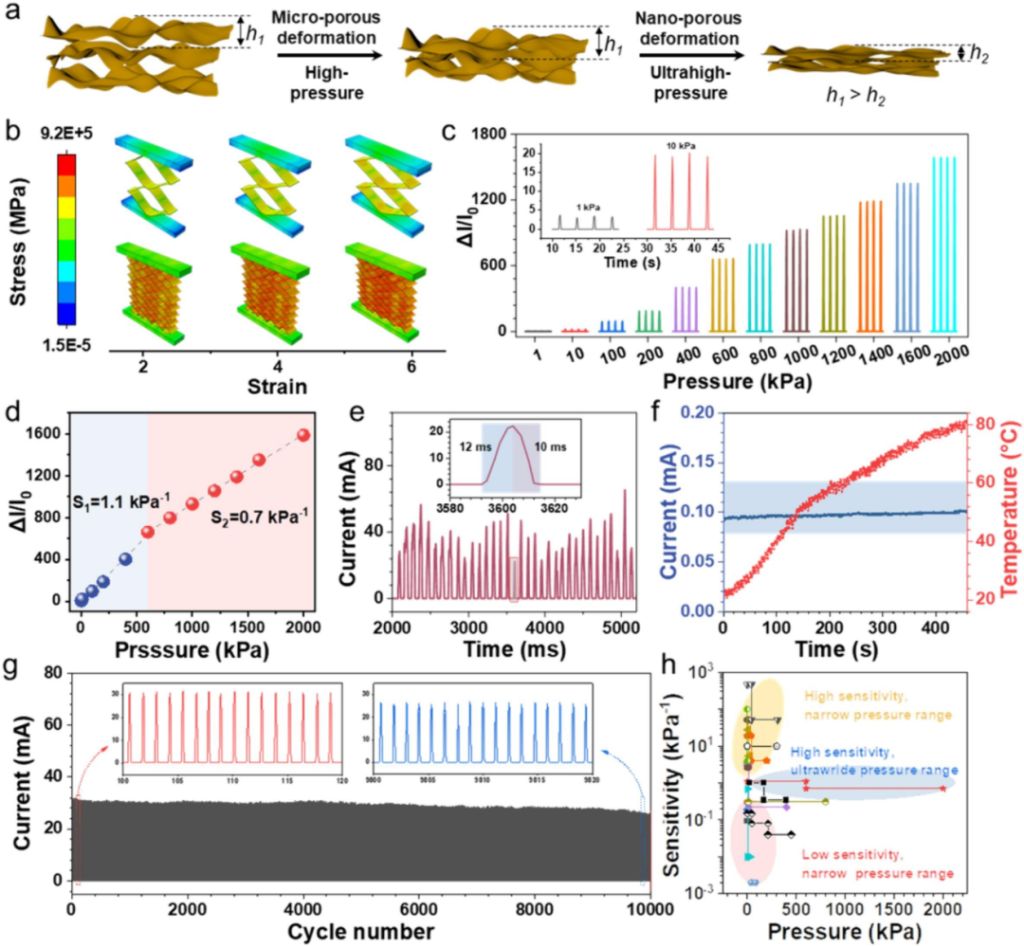

The flexible PGM sensor exhibits unprecedented high-pressure responses across pressure ranges up to 2000 kPa, with sensitivities of 1.1 kPa⁻¹ and 0.7 kPa⁻¹ in the 1-600 kPa and 600-2000 kPa pressure ranges, respectively. It also demonstrates excellent performance in high-pressure stability tests, maintaining its sensitivity after more than 10,000 cycles.

Figure 2: Two-step deformation mechanism and ultra-high pressure sensing performance of PGM

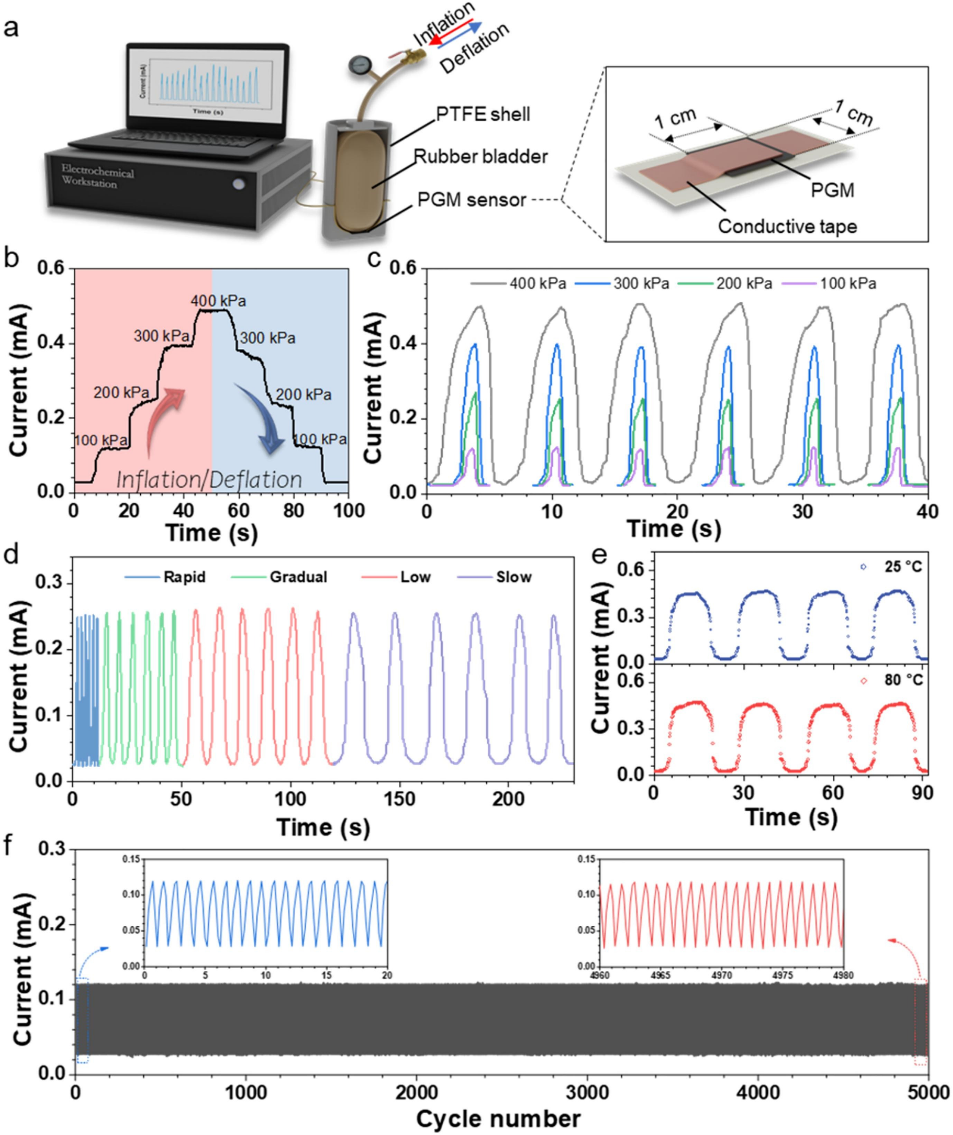

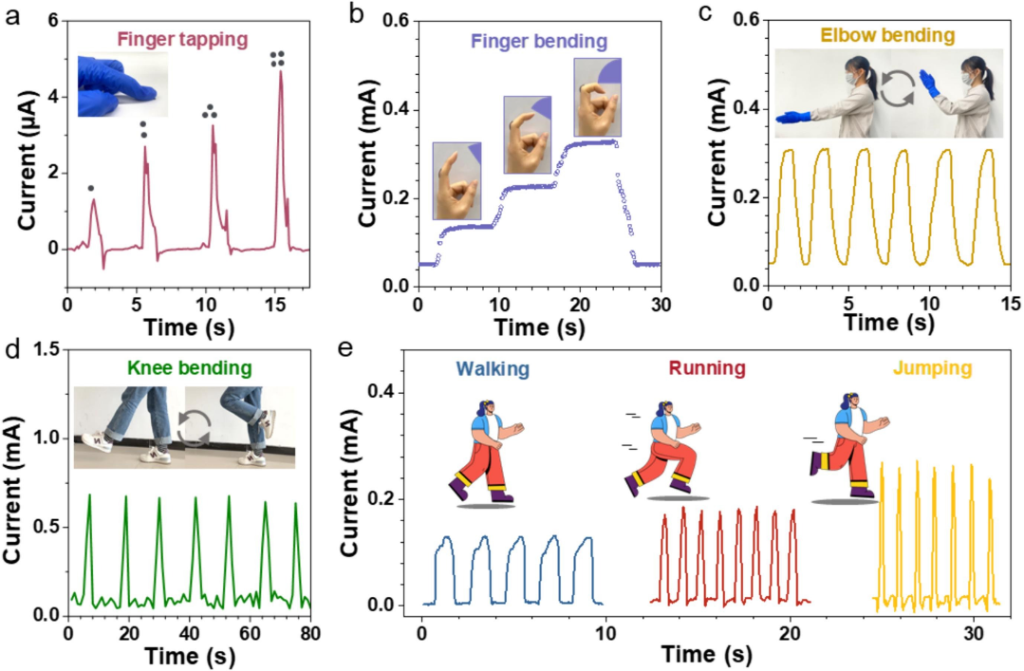

The flexible PGM sensor has made significant breakthroughs in both sensitivity and response range, demonstrating multifunctionality and stability in practical applications. It can monitor the inflation/deflation process of a pressure vessel model in real-time, as well as detect human movements such as bending of fingers, elbows, knees, and actions like walking, running, and jumping. The hierarchically porous structure of the PGM opens new avenues for developing sensors that can operate across a wide range of pressures, with potential applications in structural health monitoring, personal health care, and medical diagnostics.

Figure 3: PGM sensor monitoring the inflation/deflation process of a pressure vessel model

Figure 4: PGM sensor monitoring human movements

This research, titled “Conformational interlocking induced construction of hierarchically porous graphene membrane for ultrahigh-pressure sensing,” has been published in the Chemical Engineering Journal. Liu Cong, a Ph.D. candidate at Beijing University of Chemical Technology, is the first author, with Professors Jia Xiaolong and Meng Qinghan serving as corresponding authors. Original article: https://doi.org/10.1016/j.cej.2024.153140

Source: Graphene Alliance