Carbon Nanomaterials for High-Performance Rubber Composites: Revolutionizing Elastic Durability

🧩 Introduction: The Need for Stronger, Smarter Rubber

Rubber is everywhere—automotive tires, seals, conveyor belts, footwear, aerospace parts—yet conventional rubber materials suffer from:

-

Abrasion

-

Poor thermal stability

-

Cracking under cyclic load

-

Limited electrical or thermal conductivity

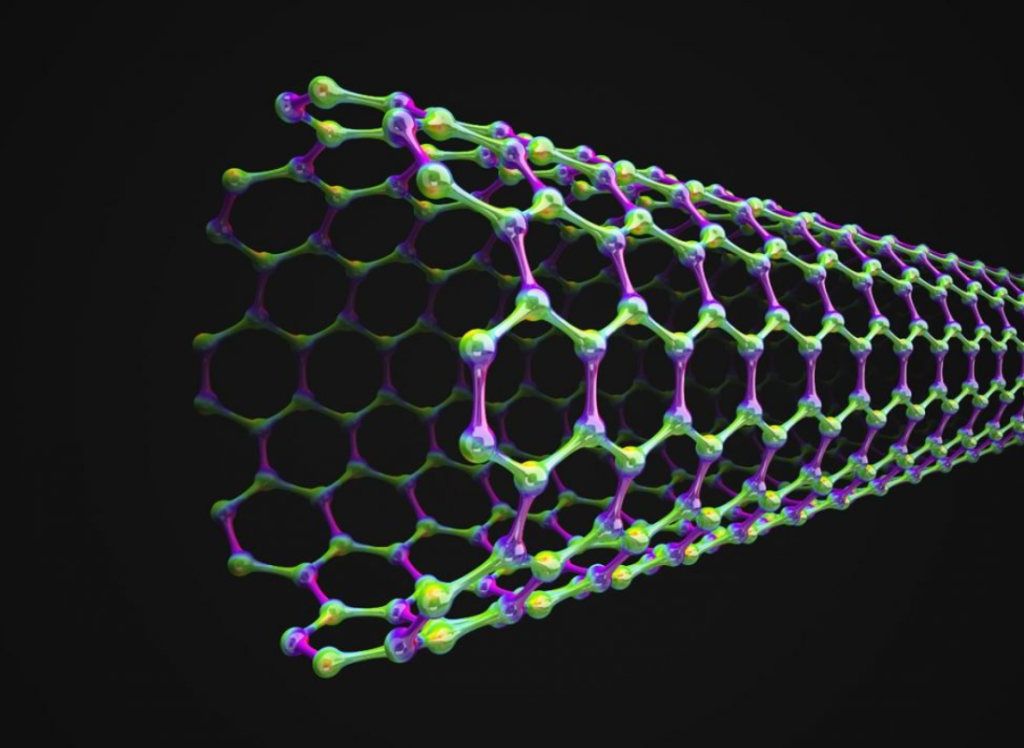

Carbon nanomaterials like carbon nanotubes (CNTs) and graphene are redefining the field of rubber composites, enabling lightweight, tough, and multi-functional elastomers with superior performance.

🧪 Part 1: Why Use Carbon Nanomaterials in Rubber?

1.1 Traditional Fillers vs. Nanofillers

| Filler Type | Example | Typical Limitations |

|---|---|---|

| Conventional | Carbon Black, Silica | High loadings required, heavy, poor multifunctionality |

| Nanomaterials | CNT, Graphene | High performance at low loading (<5%), add conductivity & strength |

1.2 Advantages of CNT & Graphene

-

Tensile strength boost (up to 2–5×)

-

Tear resistance and flex-fatigue improvement

-

Thermal conductivity for heat dissipation

-

Electrical conductivity for ESD-safe and EMI-shielded elastomers

-

Maintain or enhance flexibility and elasticity

🔬 Part 2: How They Work – Nano Reinforcement Mechanism

-

Load Transfer Efficiency

CNTs and graphene bridge microcracks and transfer stress across the matrix. -

Crack Arrest & Propagation Resistance

Nanofillers act as energy barriers during tearing or tensile deformation. -

Network Formation

Percolating networks of CNTs/graphene provide:-

Conductive pathways

-

Reinforced rubber skeleton

-

Thermal channels

-

🏗️ Part 3: Key Carbon Nanomaterials for Elastomer Composites

| Material | Type | Application Highlights |

|---|---|---|

| Multi-walled CNT (MWCNT) | Conductive & reinforcing | Tires, antistatic rubber, conveyor belts |

| Single-walled CNT (SWCNT) | Ultra-high strength | High-end sealing materials |

| Graphene Oxide (GO) | Dispersible & functional | Rubber gloves, seals |

| Reduced GO (rGO) | High conductivity | EMI shielding in flexible systems |

| Graphene nanoplatelets (GNPs) | Low cost | Bulk elastomer fillers |

🧪 Part 4: Processing Techniques & Dispersion

Achieving proper dispersion is key:

4.1 Latex Mixing

-

Introduce CNT or graphene into natural rubber latex

-

Good for gloves, balloons, flexible sensors

4.2 Melt Mixing (Internal Mixer, Two-roll Mill)

-

Incorporate nanocarbon into synthetic rubber (e.g., EPDM, SBR, NBR)

-

Ideal for tires, seals, gaskets

4.3 Solution Blending

-

Use solvent-based dispersion for specialty applications

Surface functionalization (e.g., acid treatment, surfactants) is often used to improve compatibility between nanocarbons and rubber matrices.

🚗 Part 5: Key Application Areas

5.1 Tires & Treads

-

CNT/graphene enhances:

-

Abrasion resistance

-

Rolling resistance

-

Wet traction performance

-

-

Example: CNT-silica hybrid systems for ultra-performance tires (UPT)

5.2 Seals and Gaskets

-

Better aging and thermal resistance

-

Oil resistance in automotive and aerospace seals

5.3 Antistatic & EMI-Shielding Rubber

-

Graphene or CNT adds:

-

ESD protection for electronics

-

Microwave shielding in wearable and soft electronics

-

5.4 Flexible Sensors & Stretchable Electronics

-

Rubber-CNT composites enable:

-

Strain sensors

-

Pressure detection in footwear or medical wearables

-

5.5 Industrial Belts & Dampers

-

Reinforced rubber resists cyclic wear, vibration, and mechanical fatigue

🧪 Part 6: Performance Improvements

| Property | Base Rubber | With CNT/Graphene | Improvement |

|---|---|---|---|

| Tensile Strength | 6 MPa | 18 MPa | 3× |

| Tear Resistance | 10 kN/m | 30 kN/m | 3× |

| Conductivity | 10⁻¹⁴ S/cm | >10⁻² S/cm | ESD-safe |

| Thermal Conductivity | ~0.2 W/m·K | >2.0 W/m·K | 10× |

⚙️ Even 0.5–2% loading of nanocarbons can yield dramatic improvements.

🏭 Part 7: Commercial Use & Case Studies

-

Goodyear, Michelin: Use CNTs in performance tire compounds

-

Zeon Corporation: CNT-enhanced seals for chemical resistance

-

Samsung: Flexible rubber sensors with graphene layers

❗ Challenges and Considerations

-

Aggregation risk of nanocarbons during processing

-

Cost control for mass-market applications

-

Ensuring dispersion uniformity in high-viscosity elastomers

-

Health and safety during nanoparticle handling

🔮 Future Outlook

-

Self-healing rubber using CNT conductive networks + reversible bonding

-

Recyclable elastomers using dynamic graphene-enhanced bonds

-

Smart tires and soft robotics embedded with sensor rubber

🧠 Conclusion: Nanocarbon Elastomers are the Future of Rubber

Carbon nanomaterials like CNTs and graphene are unlocking next-level rubber composites that are not just stronger, but smarter, more durable, and multifunctional.

With scalable processing techniques and falling prices of nanocarbons, nanoreinforced rubber is moving from labs to factories, ready to revolutionize transportation, electronics, industrial equipment, and more.

🧪 Nanocarbon rubber isn’t just stronger—it’s the backbone of elastic innovation for the 21st century.