Carbon Nanotube (CNT) Conductive Additives for Polymer Processing

Advanced Conductivity at Low Loading Levels

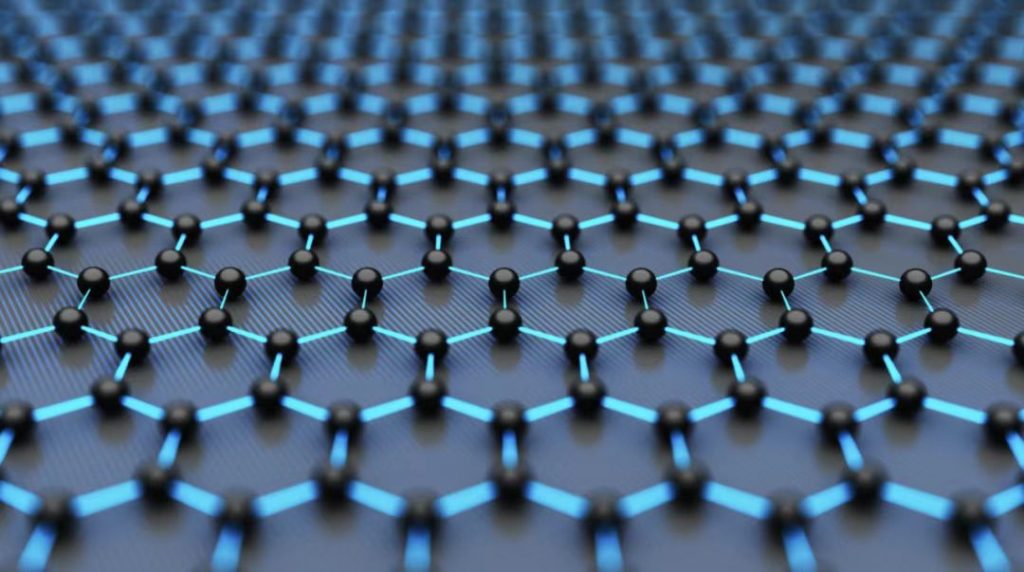

Carbon nanotube (CNT) conductive additives enable polymers to achieve reliable electrical conductivity while preserving mechanical properties, processability, and lightweight design. Compared with traditional conductive fillers, CNTs form efficient conductive networks at significantly lower loading levels, making them ideal for high-performance and functional polymer applications.

Why CNT Conductive Additives?

CNTs feature a unique one-dimensional structure with extremely high aspect ratio, allowing rapid formation of percolation networks within polymer matrices. This translates into stable electrical performance with minimal impact on material properties.

Key advantages include:

-

Ultra-low percolation threshold

-

High electrical conductivity at low filler loading

-

Excellent mechanical property retention

-

Stable conductivity under deformation and thermal cycling

-

Long-term environmental and electrical stability

CNT conductive additives are well suited for applications where performance, durability, and lightweight design are critical.

Typical Applications

CNT conductive additives are widely used across multiple polymer-based applications, including:

-

ESD (Electrostatic Discharge) Protection

Housings, trays, packaging, and precision components -

EMI Shielding

Electronic enclosures, automotive electronics, communication devices -

Conductive & Heating Components

Joule heating elements, temperature control parts -

Sensors & Smart Components

Strain sensors, pressure sensors, functional polymer parts -

Lightweight Conductive Plastics

Automotive and industrial components requiring weight reduction

Performance Advantages Compared to Traditional Fillers

| Property | CNT Additives | Carbon Black |

|---|---|---|

| Percolation threshold | Very low | High |

| Required loading level | < 1 wt% (typical) | 10–20 wt% |

| Mechanical property impact | Minimal | Significant |

| Conductivity stability | Excellent | Moderate |

| EMI shielding efficiency | High | Moderate |

CNT-based systems often enable lower total system cost by reducing filler loading, improving durability, and extending component lifetime.

Material Forms & Supply Options

Our CNT conductive additives are available in multiple forms to support different processing requirements:

-

CNT Powder – for custom compounding

-

CNT Masterbatch – optimized dispersion for injection molding and extrusion

-

Hybrid CNT Systems – CNT combined with carbon black or graphene for cost–performance balance

Customization options are available based on polymer type and target conductivity.

Processing Compatibility

CNT conductive additives are compatible with common polymer processing techniques, including:

-

Injection molding

-

Extrusion

-

Compression molding

-

Film and sheet processing

With proper formulation, CNT additives maintain good melt flow and processing stability, even at low loading levels.

Design & Formulation Support

Selecting the right CNT grade and formulation is critical for achieving optimal performance. We provide technical support throughout the development process, including:

-

Material selection guidance

-

Conductivity target definition

-

Dispersion and compounding recommendations

-

Pilot-scale testing support

Our goal is to help customers reduce development risk and accelerate commercialization.

Quality & Consistency

All CNT conductive additives are supplied with controlled specifications to ensure batch-to-batch consistency, supporting stable processing and long-term performance in industrial production.

Why Work With Us

-

Focus on application-driven material solutions

-

Experience across polymers, conductive systems, and functional composites

-

Flexible supply options from sampling to scale-up

-

Long-term technical collaboration mindset

We do not simply supply materials—we support engineering decisions.

Get in Touch

Looking to improve conductivity in your polymer system while maintaining mechanical performance?

Contact us to discuss your application requirements, and our technical team will support you with material selection and formulation guidance.