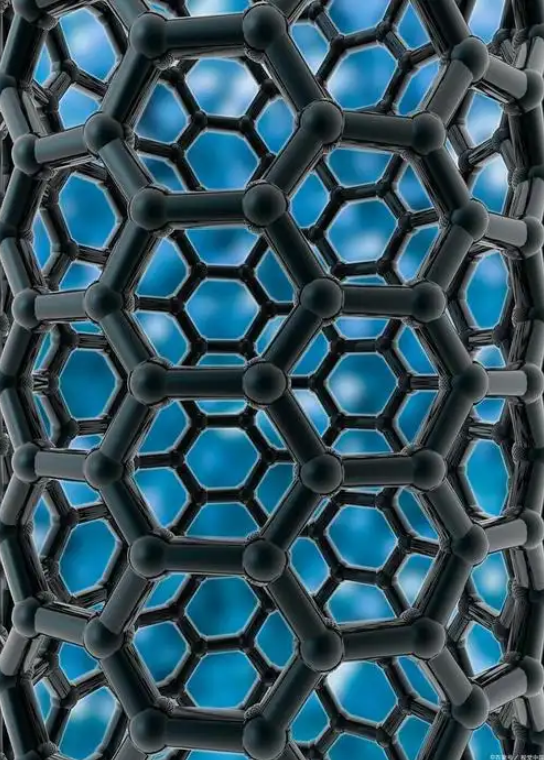

Carbon Nanotubes and Graphene Composites in High-Strength Structural Components

Introduction

The advancement of electric tools, robotics, and industrial automation heavily depends on the development of high-strength, lightweight materials. As industries push towards more efficient and durable solutions, the combination of carbon nanotubes (CNTs) and graphene in composite materials has emerged as a transformative innovation. These advanced materials enable significant improvements in mechanical strength, weight reduction, and durability, making them ideal for robotic structural components, aerospace, and high-performance manufacturing.

This article explores how CNT-graphene composites are being integrated into high-strength industrial applications, particularly in robotic structures, where they enhance load capacity, wear resistance, and structural integrity.

1. Why Use Carbon Nanotubes and Graphene Composites?

The combination of CNTs and graphene offers superior properties that make them ideal for structural applications:

- High Mechanical Strength: These composites exhibit exceptional tensile strength, making them stronger than steel at a fraction of the weight.

- Lightweight Design: The low density of CNTs and graphene enables weight reduction in robotic and industrial applications.

- Superior Durability: High resistance to wear, impact, and environmental conditions enhances the longevity of components.

- Excellent Electrical and Thermal Conductivity: These materials improve heat dissipation and structural monitoring in high-performance applications.

- Corrosion and Fatigue Resistance: CNT-graphene composites exhibit improved chemical stability, making them suitable for harsh environments.

These benefits contribute to more efficient, reliable, and high-performance structural components for modern automation and manufacturing.

2. Key Applications of CNT-Graphene Composites in Structural Components

(1) High-Strength Robotic Frames and Arms

Industrial robots and automation systems require lightweight yet strong materials to ensure stability and efficiency.

- CNT-graphene composites reduce overall weight while maintaining high load-bearing capacity.

- These materials improve the flexibility and impact resistance of robotic arms, enabling smoother operation.

- Enhanced durability ensures that robots perform consistently in high-stress manufacturing environments.

(2) Aerospace and Automotive Structural Components

The aerospace and automotive industries demand high-strength, lightweight materials for improved efficiency.

- Graphene-CNT composites enhance fuel efficiency by reducing structural weight in aircraft and automobiles.

- Increased impact resistance ensures safety in crash-prone applications.

- These composites are used in chassis, panels, and reinforcement structures, optimizing performance in extreme conditions.

(3) Load-Bearing and Protective Structures in Manufacturing

Manufacturing environments require materials that can withstand mechanical stress, vibration, and corrosion.

- CNT-graphene composites improve wear resistance, ensuring longer-lasting structural elements in factories.

- These materials are ideal for protective casings, machine enclosures, and heavy-duty structural supports.

- Their chemical and thermal stability makes them perfect for high-temperature and corrosive settings.

(4) High-Performance Sporting Equipment

Lightweight, strong materials are crucial in sports equipment such as bicycles, helmets, and protective gear.

- CNT-graphene composites provide better strength-to-weight ratios than conventional materials.

- Improved shock absorption enhances safety in extreme sports and professional athletics.

- Their resistance to environmental degradation ensures long-term performance.

3. Advantages of CNT-Graphene Composites Over Traditional Materials

| Feature | Traditional Materials | CNT-Graphene Composites |

|---|---|---|

| Mechanical Strength | Limited, prone to wear and fatigue | High tensile strength, highly durable |

| Weight | Heavy, adds unnecessary load | Lightweight, reduces overall weight |

| Corrosion Resistance | Requires coatings for protection | Naturally resistant to oxidation and corrosion |

| Thermal Conductivity | Moderate, may require cooling solutions | Excellent heat dissipation, prevents overheating |

| Structural Flexibility | Stiff and brittle | High flexibility with superior impact resistance |

| Energy Efficiency | Heavier components increase energy use | Lightweight structures improve efficiency |

With these improvements, CNT-graphene composites are revolutionizing industrial applications, offering unmatched performance benefits.

4. Market Potential and Industry Adoption

The demand for high-performance structural materials is rapidly increasing across multiple industries. Key factors driving the adoption of CNT-graphene composites include:

- Growing demand for lightweight, high-strength materials in robotics and aerospace.

- Advancements in nanotechnology, making large-scale production of CNT-graphene composites more viable.

- Increased focus on sustainability, as these materials reduce waste and improve energy efficiency.

- Adoption in high-tech industries, including automotive, defense, and precision manufacturing.

Market projections indicate that CNT-graphene composite adoption will continue to grow, with expanding applications in next-generation automation and engineering.

Conclusion

Carbon nanotube and graphene composites are transforming high-strength structural applications, offering unparalleled mechanical performance, durability, and weight reduction. By enhancing robotic frames, aerospace structures, and industrial components, these materials enable smarter, more efficient manufacturing and automation.

As research and development continue, CNT-graphene composites will play a pivotal role in future engineering, providing advanced, sustainable solutions for next-generation industries.

For businesses and manufacturers, investing in CNT-graphene-enhanced materials will ensure greater efficiency, reliability, and competitiveness in the evolving landscape of industrial and structural engineering.