Introduction

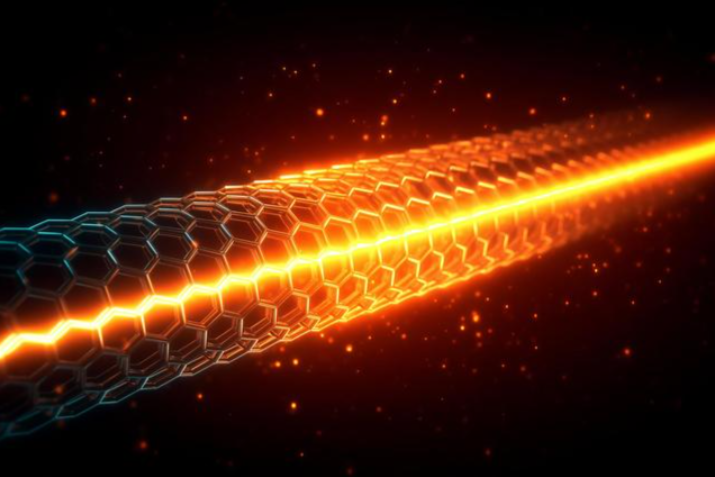

As electronic devices continue to miniaturize while increasing in power density, thermal management becomes a bottleneck for performance and reliability. A core component of thermal design is the Thermal Interface Material (TIM) — the layer between heat-generating chips and heat sinks. Traditional materials like silicone grease or metallic pastes are reaching their limits. Carbon nanotubes (CNTs) offer a new frontier in TIM technology, delivering ultra-high thermal conductivity, durability, and nano-scale contact compliance.

1. What Makes CNTs Ideal for TIMs?

-

Thermal Conductivity: CNTs exhibit values >3000 W/m·K (for SWCNTs), vastly superior to most polymers or even metals

-

High Aspect Ratio: Ensures efficient heat conduction pathways even at low loading levels

-

Mechanical Resilience: CNTs maintain thermal contact even under pressure, reducing contact resistance over time

-

Electrically Tunable: Can be used in insulating or conductive TIM formulations

2. Types of CNT-Based TIMs

a. CNT-Polymer Composites

-

Epoxy + CNT paste: Used for CPU, GPU packaging

-

Silicone grease + CNTs: Improved spreadability and heat flow

-

Challenges: Dispersion, agglomeration prevention

-

Solutions: Functionalization (COOH, NH₂), sonication, surfactant blending

b. Vertically Aligned CNT Arrays (VA-CNTs)

-

CNTs grown perpendicularly from substrate

-

Act as compressible thermal “springs”

-

Offer ultra-low thermal resistance

-

Applicable in high-power electronics (e.g., IGBTs, RF modules)

c. CNT Films and Sheets

-

Flexible conductive sheets for wearable electronics, LED panels

-

Sometimes combined with graphene to balance conductivity and flexibility

3. Performance Comparison

| TIM Material | Thermal Conductivity (W/m·K) | Electrical Conductivity | Flexibility | Stability |

|---|---|---|---|---|

| Traditional Grease | 1–4 | Low | Medium | Poor (dry out) |

| CNT-Epoxy Composite | 5–20 | Adjustable | Good | High |

| VA-CNT Array | >50 | High | Excellent | Very High |

4. Application Areas

-

Consumer Electronics: Smartphones, laptops, gaming consoles

-

Data Centers: Thermal pads for high-density CPU/GPU boards

-

Electric Vehicles (EVs): Power electronics cooling

-

LED Modules: Maintaining brightness and lifespan

-

5G & RF Modules: Low-profile, high-efficiency heat spreaders

5. Case Studies

-

IBM: Demonstrated vertically aligned CNT TIMs with 10x lower thermal resistance than silver paste

-

Toshiba: Integrated CNT grease in laptop CPUs for noise-free passive cooling

-

Chinese EV suppliers: Exploring CNT films in battery management system (BMS) heat sinks

6. Manufacturing and Integration

-

Growth Methods: CVD is used for aligned arrays; solution blending for composites

-

Scalability: Pilot-scale batches are now available; roll-to-roll fabrication of CNT sheets is under progress

-

Cost Trends: CNT paste costs have dropped to <$20/kg in composite form

7. Challenges and Future Directions

-

Contact Resistance Stability: Research is ongoing on maintaining intimate contact under thermal cycling

-

Mechanical Fatigue: Addressed via hybrid structures with CNT + graphene + polymer

-

Regulatory and Safety: Ensuring CNTs are immobilized in safe matrices

Conclusion

CNT-based TIMs are no longer experimental—they are being evaluated and adopted in high-performance electronics where thermal efficiency is critical. With increasing demand from consumer devices, electric vehicles, and high-power systems, CNT thermal interface materials promise to redefine heat transfer efficiency, unlocking performance and longevity in the next generation of electronic hardware.