Carbon Nanotubes in Aerospace Composites: Strength, Weight, and Heat Resistance Redefined

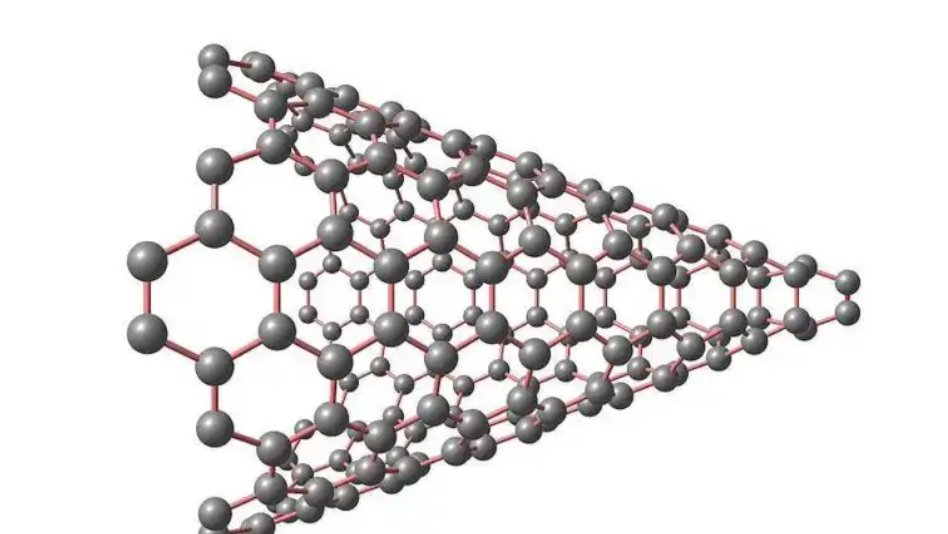

Aerospace engineering continuously seeks materials that deliver high strength-to-weight ratios, thermal stability, and resistance to fatigue and environmental degradation. Carbon nanotubes (CNTs), with their exceptional mechanical, thermal, and electrical properties, are now at the forefront of next-generation aerospace composite design.

Why Aerospace Needs Better Composites

Aircraft and spacecraft components are subjected to extreme conditions:

-

High vibration and mechanical stress

-

Wide temperature fluctuations

-

Strict weight limitations

-

Demands for long-term durability

While traditional carbon fiber composites offer high performance, CNTs can elevate that performance further—by reinforcing matrices at the nanoscale level.

Properties of Carbon Nanotubes That Benefit Aerospace

-

Tensile Strength: CNTs have strength 100x greater than steel, with only a fraction of the weight.

-

Thermal Conductivity: Excellent heat dissipation helps prevent hotspots in structural components.

-

Electrical Conductivity: Useful in de-icing systems, lightning strike protection, and EMI shielding.

-

Fatigue Resistance: Enhances lifecycle and reliability of aerospace parts.

Key Aerospace Applications

1. Structural Reinforcements

CNTs are incorporated into polymer matrices or used alongside carbon fibers to create multi-scale composites. These materials are used in fuselage panels, wing sections, and landing gear supports.

2. Thermal Protection Systems (TPS)

CNT-based composites are being tested for use in reentry vehicle heat shields and hypersonic aircraft skins, where materials must withstand 1000°C+ without degradation.

3. Lightweight Cabling and Wiring

CNT fibers offer high conductivity at ultra-low weight—enabling lighter electrical systems for satellites, drones, and space vehicles.

4. Lightning Strike Protection

The integration of conductive CNT coatings helps safely channel electrical discharges in composite-bodied aircraft, replacing heavier metallic meshes.

Industry Adoption Examples

-

NASA and Boeing are exploring CNT-based laminates for next-gen aircraft.

-

Airbus has trialed CNT-infused paint as a lightning protection system.

-

SpaceX and Blue Origin have expressed interest in using CNT composites for reusable rockets and engine insulation.

Technical Challenges

The aerospace-grade use of CNTs faces hurdles like:

-

Uniform dispersion in resins and polymers

-

Scalable manufacturing of CNTs with consistent quality

-

Interfacial bonding between CNTs and matrix materials

Researchers are tackling these through functionalization techniques, hybrid fillers, and advanced processing methods.

The Future of CNT Aerospace Materials

As global aerospace firms transition to greener, lighter, and faster platforms, CNTs will play an increasingly vital role. The synergy between mechanical strength, thermal conductivity, and electrical performance makes them ideal for multifunctional design.

Carbon nanotubes are redefining the boundaries of aerospace materials. Their integration into advanced composites paves the way for safer, lighter, and more efficient aircraft and spacecraft. As R&D matures, CNTs are poised to become a cornerstone of 21st-century aerospace engineering.