Carbon Nanotubes in Aerospace Composites: Strength Without Weight

The aerospace industry is one of the most demanding engineering sectors, requiring materials that can withstand extreme stress, temperature variations, and long service lifetimes while maintaining lightweight properties. Every kilogram saved on an aircraft translates directly into fuel savings and reduced emissions, which is why advanced composites are central to modern aerospace design.

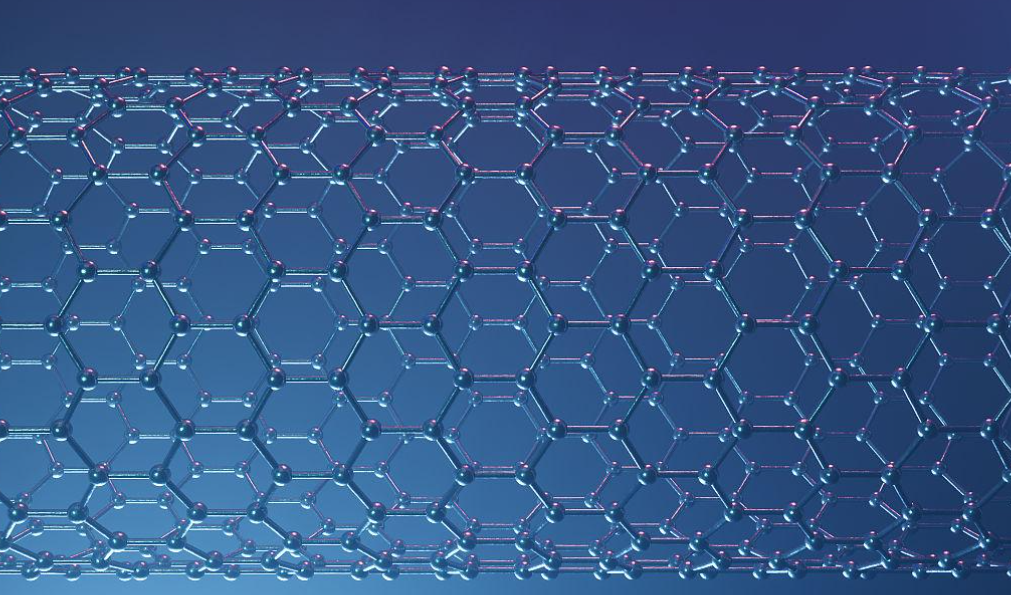

Among the new materials being explored, carbon nanotubes (CNTs) are gaining significant attention. Their exceptional strength-to-weight ratio, electrical conductivity, and thermal stability make them ideal candidates for enhancing aerospace composites. By integrating CNTs into polymer, ceramic, or metal matrices, engineers can design next-generation aerospace structures that are lighter, stronger, and more efficient.

Why Carbon Nanotubes for Aerospace?

Carbon nanotubes have several unique advantages that make them attractive for aerospace applications:

-

Extraordinary Mechanical Strength – CNTs have tensile strengths up to 100 times greater than steel while being much lighter.

-

Low Density – Ultra-lightweight, contributing to overall mass reduction of aerospace structures.

-

Thermal Stability – Withstand high operating temperatures, ideal for engines and hypersonic aircraft.

-

Electrical Conductivity – Useful for lightning strike protection and electromagnetic interference (EMI) shielding.

-

Multifunctionality – Enable structural health monitoring by embedding sensing capability within composites.

Key Aerospace Applications

1. Lightweight Structural Composites

-

CNTs can reinforce polymer composites used in fuselage, wings, and interior structures.

-

The addition of CNTs improves fracture toughness, fatigue resistance, and stiffness.

-

Boeing and Airbus are actively testing CNT-reinforced composites to replace traditional carbon fiber-reinforced plastics (CFRPs).

2. Thermal Protection Systems

-

CNTs are excellent thermal conductors, making them suitable for heat shields and thermal management systems.

-

In spacecraft, CNT-based composites can protect against the extreme temperature fluctuations during re-entry.

-

Hypersonic vehicles could rely on CNT composites to handle continuous exposure to 1000°C+ conditions.

3. Electromagnetic Shielding and Lightning Protection

-

Aircraft and satellites are exposed to strong electromagnetic radiation and lightning strikes.

-

CNT composites offer lightweight electrical conductivity, allowing them to replace heavy copper meshes currently used for lightning strike protection.

-

This reduces overall aircraft mass while improving safety.

4. Propulsion Systems

-

CNTs can reinforce ceramic matrix composites (CMCs) in jet engines, improving their strength and oxidation resistance.

-

Potential to extend the lifetime of turbine blades and reduce cooling requirements.

-

CNTs are also being studied for lightweight rocket nozzles and fuel system components.

5. Satellite and Spacecraft Applications

-

CNT composites are being tested for solar panels, antenna structures, and lightweight trusses.

-

High radiation resistance and mechanical durability make CNTs suitable for space environments.

-

NASA has explored CNT-based tethers for orbital propulsion systems due to their strength-to-weight benefits.

Advantages Over Conventional Aerospace Materials

| Property | Aluminum Alloys | CFRPs (Carbon Fiber) | CNT Composites |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 1.6 | <1.4 |

| Tensile Strength (GPa) | 0.4–0.6 | 2–5 | 10–50+ |

| Thermal Conductivity | Moderate | Low | Very High |

| Electrical Conductivity | Low | Low | High |

| Fatigue Resistance | Moderate | High | Very High |

Challenges to Overcome

While CNTs show remarkable promise, there are hurdles to address before widespread adoption in aerospace:

-

Scalable Manufacturing – Producing defect-free CNTs in large volumes at low cost remains a challenge.

-

Uniform Dispersion – CNTs tend to bundle together; ensuring even distribution within composites is critical.

-

Standardization – Aerospace requires rigorous testing, certification, and compliance before adoption.

-

Long-Term Durability – CNT composites must be validated for decades-long service life in harsh conditions.

Future Outlook

The next decade is expected to see increasing use of CNTs in aerospace as manufacturing processes improve. Key trends include:

-

Hybrid Composites – Combining CNTs with carbon fibers or graphene for multifunctional properties.

-

Self-Healing Materials – CNTs can act as nanoscale reinforcements that repair microcracks under stress.

-

3D Printing with CNTs – Additive manufacturing of aerospace components with CNT-infused polymers and metals.

-

Sustainable Aviation – Lighter and stronger CNT composites contribute to lower fuel consumption and reduced carbon emissions.

Given the aerospace industry’s continuous push for performance and efficiency, carbon nanotube composites are positioned to play a transformative role in next-generation aircraft and spacecraft.

Carbon nanotubes hold the potential to revolutionize aerospace composites by combining strength, lightweight properties, thermal stability, and electrical conductivity in a single material. From fuselages to engines and satellites, CNT-based composites promise performance improvements that traditional materials cannot achieve.

Although challenges such as large-scale manufacturing and certification remain, the trajectory is clear: the aerospace industry is moving toward CNT composites as the materials of the future.