Introduction

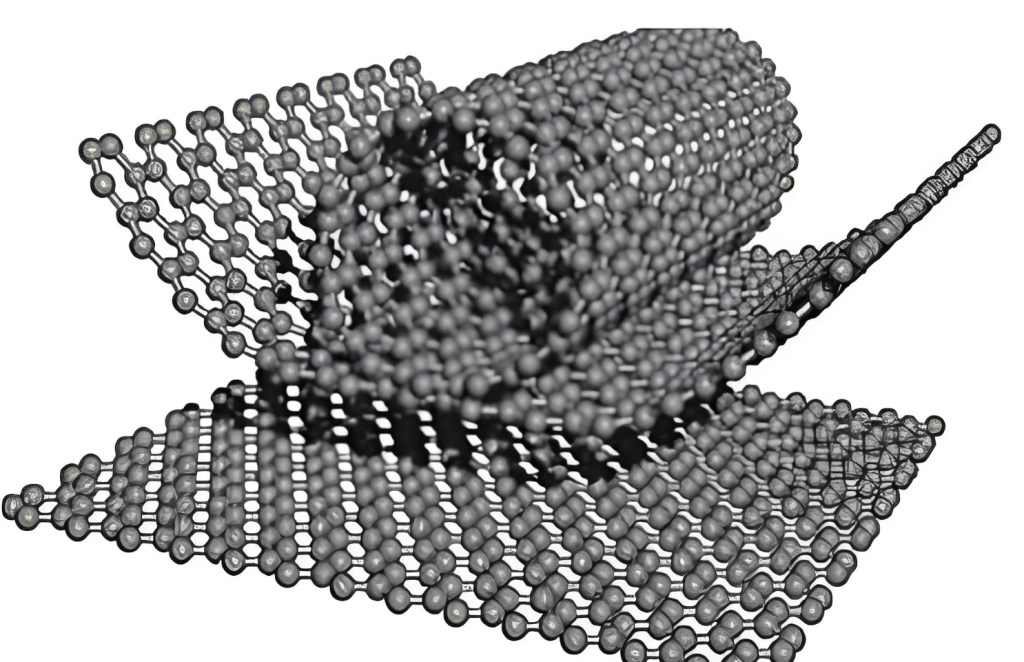

The aerospace industry has always been driven by the need for lighter, stronger, and more efficient materials. Whether in satellites, aircraft, or spacecraft, material science innovation is central to improved fuel efficiency, thermal stability, and structural resilience. One material gaining rapid attention in this sector is the carbon nanotube (CNT)—a cylindrical carbon structure with unmatched strength-to-weight ratio, conductivity, and thermal stability.

This article explores how carbon nanotubes are reshaping aerospace engineering by enhancing composite materials, structural performance, EMI shielding, and thermal management.

1. Why CNTs Matter for Aerospace

a. High Strength-to-Weight Ratio

CNTs have tensile strengths over 100x higher than steel while weighing far less, enabling lighter aircraft frames and fuel efficiency.

b. Electrical Conductivity

CNTs improve static dissipation and lightning strike protection in composite aircraft parts.

c. Thermal Conductivity

Excellent heat conduction makes CNTs ideal for protecting sensitive electronics in satellites and high-speed aircraft.

d. Radiation Shielding

Single-walled CNTs (SWCNTs) have demonstrated absorption of cosmic radiation, crucial for long-term space missions.

2. CNT-Reinforced Aerospace Composites

a. Carbon Fiber Reinforced Polymers (CFRP)

By adding CNTs to CFRPs:

-

Matrix cracking is reduced

-

Interfacial adhesion improves

-

Fatigue resistance is enhanced

This is critical for wing panels, fuselage sections, and rotor blades.

b. Resin Matrix Enhancement

Epoxy or thermoplastic matrices doped with CNTs:

-

Exhibit increased fracture toughness

-

Improve delamination resistance

-

Allow for thinner, lighter laminate layers

This contributes to aerospace structural optimization.

3. Thermal and EMI Management

a. Thermal Interfaces for Satellites and Avionics

CNTs can serve in:

-

Thermal Interface Materials (TIMs)

-

Heat spreaders for circuit boards

-

Antenna or radar cooling systems

Their high thermal conductivity (~3000–6000 W/m·K) ensures stable electronics in extreme altitudes or space conditions.

b. EMI Shielding in Avionics

Electromagnetic interference (EMI) is a growing concern. CNT films and foams:

-

Offer 20–40 dB shielding effectiveness

-

Replace metal meshes at reduced weight

-

Protect navigation, communication, and radar systems

4. Structural Health Monitoring

CNTs integrated into polymers or coatings can form self-sensing nanocomposites. These materials can:

-

Detect microcracks

-

Monitor stress-strain behavior

-

Provide real-time alerts for maintenance

This supports predictive maintenance and improved aircraft safety.

5. Additive Manufacturing and CNTs

a. 3D Printed CNT Composites

New technologies are exploring CNT-enhanced inks for 3D printing lightweight aerospace parts, enabling:

-

Customized geometries

-

Integrated electrical pathways

-

On-demand repairs in space

b. Multi-material Manufacturing

Researchers are combining CNTs with:

-

Kevlar

-

Polyether ether ketone (PEEK)

-

Metal alloys (like Al or Ti)

to create multifunctional aerospace-grade components.

6. Key Players and Research Trends

-

NASA: Exploring CNT thermal solutions for Mars and lunar missions

-

Boeing and Airbus: Researching CNT-reinforced carbon composites for next-gen jets

-

Lockheed Martin: Studied CNTs for structural monitoring systems

-

MIT and Stanford: Leading academic institutions modeling CNT-enhanced wings and fuselages

7. Challenges and Solutions

a. Dispersion and Alignment

CNTs often clump, reducing performance. Solutions include:

-

Functionalization (e.g., carboxylation)

-

Ultrasonic dispersion

-

Shear mixing techniques

b. Cost and Scalability

While CNTs remain more expensive than carbon fibers, prices are falling. Advances in CVD synthesis and CNT forests are promising for aerospace-scale production.

Conclusion

Carbon nanotubes offer tremendous potential for the aerospace sector—from structural reinforcement and lightweighting to thermal protection and real-time diagnostics. As supply chains mature and integration techniques improve, CNTs are expected to become standard in the future of aerospace innovation—helping mankind fly further, faster, and safer.