Carbon Nanotubes in EV Battery Slurries: Boosting Conductivity and Stability

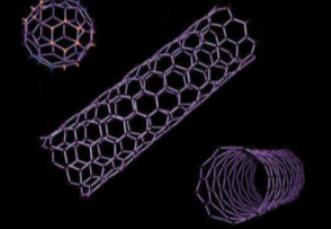

As electric vehicles (EVs) grow in popularity, the demand for high-performance, fast-charging, and stable lithium-ion batteries intensifies. One crucial component often overlooked is the battery slurry—the mixture used to cast electrodes. In recent years, carbon nanotubes (CNTs) have become the preferred conductive additive in battery slurries, replacing traditional carbon black due to their superior electrical and structural properties.

🔹 1. What Is a Battery Slurry?

Battery slurry is a viscous mix of:

-

Active material (e.g., LiFePO₄, NMC)

-

Conductive agents (carbon black, CNTs)

-

Binders (e.g., PVDF)

-

Solvent (usually NMP or water-based)

This slurry is coated onto a copper (anode) or aluminum (cathode) current collector and dried to form electrode films.

🔹 2. Limitations of Carbon Black in EV Applications

While cheap and widely used, carbon black:

-

Has poor conductivity per weight

-

Requires large loading (~3–6 wt%)

-

Tends to agglomerate, hurting uniformity

-

Weakens the electrode’s mechanical integrity

In contrast, CNTs offer a high-aspect-ratio conductive network that performs better at lower loadings.

🔹 3. Advantages of CNTs in Slurries

| Property | Carbon Black | Carbon Nanotubes |

|---|---|---|

| Conductivity | Moderate | 10–100× higher |

| Loading requirement | 3–6 wt% | ~0.5–1 wt% |

| Dispersion | Agglomerates | Uniform, network-forming |

| Mechanical strength | Weak cohesion | Strong interconnection |

Benefits:

-

Higher rate capability

-

Greater cycling stability

-

Lower internal resistance (IR drop)

-

Lighter, more energy-dense cells

🔹 4. Real-World Impact on EV Batteries

a. Cathode Formulations:

-

CNTs improve electron transport in high-Ni NMC, LFP, or LMO

-

Enhance electrode adhesion → reduce cracking on cycling

b. Anode Formulations:

-

CNTs as conductive matrix in Si–graphite hybrid anodes

-

Buffering against volume expansion of Si

c. Slurry Rheology:

-

CNTs improve flow behavior

-

Allow faster coating speeds → higher throughput

🔹 5. Dispersion Techniques

Proper dispersion is critical:

-

Ultrasonication or high-shear mixing needed

-

Use of surfactants or dispersants (e.g., SBR, CMC)

-

Water-based slurries becoming more common

Pre-dispersed CNT pastes and masterbatches are used by:

-

Tesla suppliers (e.g., LG, CATL)

-

Panasonic, SK On, BYD

🔹 6. Economic and Environmental Considerations

Although CNTs are more expensive per kg than carbon black, their low loading and superior performance often make them cost-effective in EVs. Manufacturers also reduce binder amounts, improving recyclability and reducing solvent use.

Emerging trends:

-

Functionalized CNTs for improved compatibility

-

Graphene–CNT hybrids for combined benefits

-

Green solvents for sustainable processing

Carbon nanotubes are revolutionizing battery slurry design, offering lightweight, conductive, and stable formulations ideal for electric vehicles. As the EV industry continues to evolve, CNT-enhanced electrodes will play a central role in achieving faster charge times, higher range, and safer batteries.