Carbon Nanotubes in Flexible Transparent Conductors: A Sustainable Alternative to ITO

Transparent conductive films (TCFs) are critical components in modern electronics, including touchscreens, flexible displays, OLEDs, and thin-film solar cells. Traditionally, indium tin oxide (ITO) has dominated the market due to its excellent electrical conductivity and optical transparency. However, ITO suffers from several drawbacks: it is brittle, expensive, and relies on scarce indium resources.

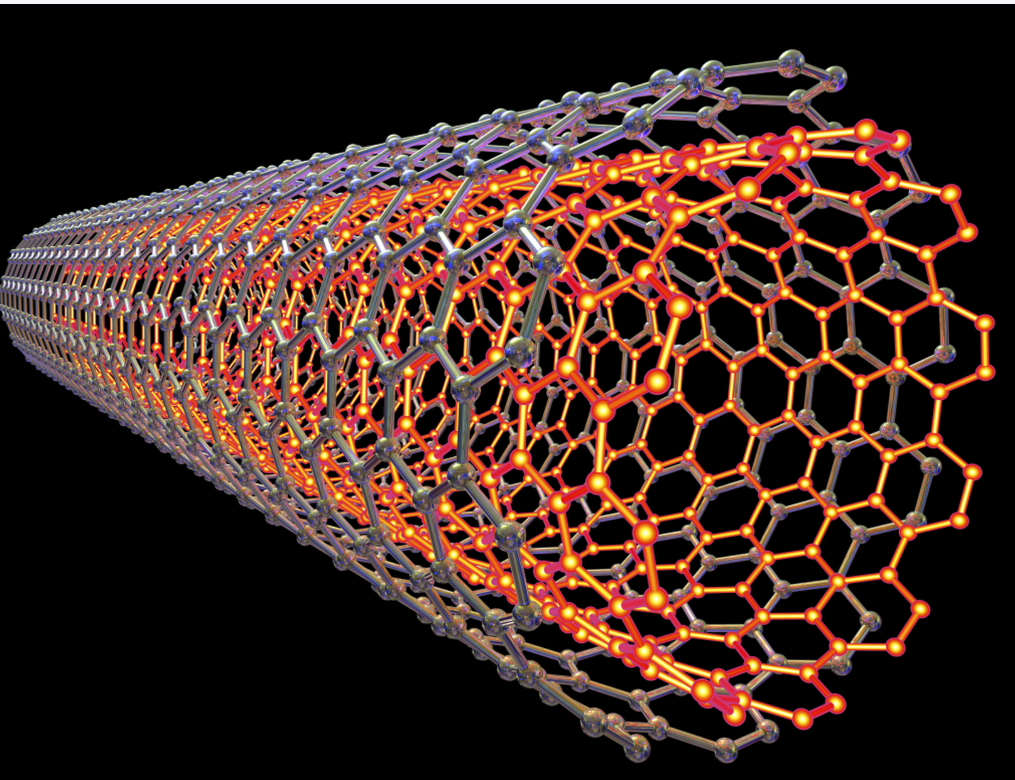

Carbon nanotubes (CNTs) have emerged as a promising alternative. With their combination of flexibility, conductivity, and optical transparency, CNT-based films offer a sustainable, high-performance solution for next-generation electronics.

Why Carbon Nanotubes Are Ideal for Flexible Transparent Conductors

CNTs possess several properties that make them suitable for TCFs:

-

High Electrical Conductivity – Single-walled and multi-walled CNTs provide excellent electron transport.

-

Optical Transparency – Thin CNT networks allow visible light to pass with minimal absorption.

-

Mechanical Flexibility – CNT films can bend, stretch, and twist without cracking, unlike brittle ITO.

-

Chemical Stability – Resistant to oxidation and environmental degradation.

-

Scalability – Can be deposited via solution processing, spray coating, or roll-to-roll techniques.

Applications Across Industries

1. Flexible Displays and Wearable Electronics

-

CNT films enable bendable, foldable, and rollable screens.

-

Touch sensors made with CNT networks maintain conductivity under repeated flexing.

-

Ideal for smartwatches, fitness bands, and foldable smartphones.

2. Solar Cells and Energy Devices

-

CNT transparent electrodes replace ITO in organic and perovskite solar cells.

-

Their flexibility allows integration into curved or portable solar panels.

-

CNT networks can improve device stability under thermal or mechanical stress.

3. Automotive and Aerospace Applications

-

Transparent heaters, defogging windows, and flexible displays benefit from CNT electrodes.

-

Lightweight CNT films reduce overall vehicle weight compared to glass-based ITO panels.

-

Mechanical durability ensures long-term performance in harsh conditions.

CNT vs. Graphene and ITO

| Property | ITO | Graphene | CNT Networks |

|---|---|---|---|

| Conductivity | High | High | Medium-High |

| Optical Transparency | Excellent | Excellent | Excellent |

| Flexibility | Poor | Good | Excellent |

| Cost | High | Medium | Medium-Low |

| Scalability | Limited | Improving | High |

CNT networks excel in mechanical flexibility and durability, making them particularly suitable for wearable and flexible electronics where ITO fails.

Fabrication Techniques

-

Spray-Coating – Scalable for large-area flexible substrates.

-

Spin-Coating – Uniform CNT networks on small surfaces.

-

Vacuum Filtration – Produces high-purity, high-performance films.

-

Roll-to-Roll Processing – Enables industrial-scale manufacturing.

Post-processing methods, like acid doping or thermal annealing, improve conductivity while maintaining transparency.

Challenges

-

Uniformity – Achieving consistent CNT dispersion and film coverage is critical.

-

Contact Resistance – Junctions between CNTs can reduce overall conductivity.

-

Cost of High-Purity CNTs – While cheaper than ITO, high-quality CNT production remains a consideration.

-

Integration – Ensuring compatibility with various substrates and device architectures requires engineering optimization.

Future Outlook

CNT-based TCFs have tremendous potential:

-

Hybrid Films – Combining CNTs with graphene or metallic nanowires can boost conductivity while retaining flexibility.

-

Stretchable Electronics – CNT networks can be integrated into wearable patches, medical sensors, and robotics.

-

Sustainable Manufacturing – Solution-processable CNTs allow low-temperature, low-waste production.

As demand grows for foldable smartphones, wearable devices, and flexible photovoltaics, CNT transparent conductors are positioned to replace ITO in many applications.

Carbon nanotubes offer a flexible, durable, and sustainable alternative to traditional ITO electrodes. Their combination of electrical conductivity, optical transparency, and mechanical flexibility makes them ideal for flexible displays, wearable electronics, solar cells, and automotive applications. Continued innovation in CNT production, hybridization, and device integration will accelerate the adoption of this next-generation material in the electronics industry.