Carbon Nanotubes in High-Capacity Lithium-Sulfur Batteries

Lithium-sulfur (Li-S) batteries have attracted significant attention as a next-generation energy storage technology due to their theoretical energy density of ~2,600 Wh/kg, which is about 5 times higher than conventional lithium-ion batteries. However, the commercialization of Li-S batteries has been hindered by several challenges, including poor electrical conductivity of sulfur, polysulfide shuttle effect, and structural instability during cycling. Carbon nanotubes (CNTs), with their unique combination of electrical conductivity, mechanical strength, and high surface area, have emerged as a promising solution to these issues.

Why Lithium-Sulfur Batteries?

Compared to lithium-ion batteries, Li-S batteries offer:

-

Higher Energy Density: Potentially enabling electric vehicles (EVs) with over 1,000 km range.

-

Lower Cost: Sulfur is abundant and inexpensive compared to cobalt and nickel used in conventional cathodes.

-

Environmental Friendliness: Sulfur is non-toxic and more environmentally sustainable.

Yet, their commercial viability is challenged by:

-

Low electrical conductivity of sulfur and lithium sulfide (Li₂S).

-

Dissolution and migration of lithium polysulfides during cycling, causing capacity fading.

-

Significant volumetric expansion (~80%) of sulfur upon lithiation.

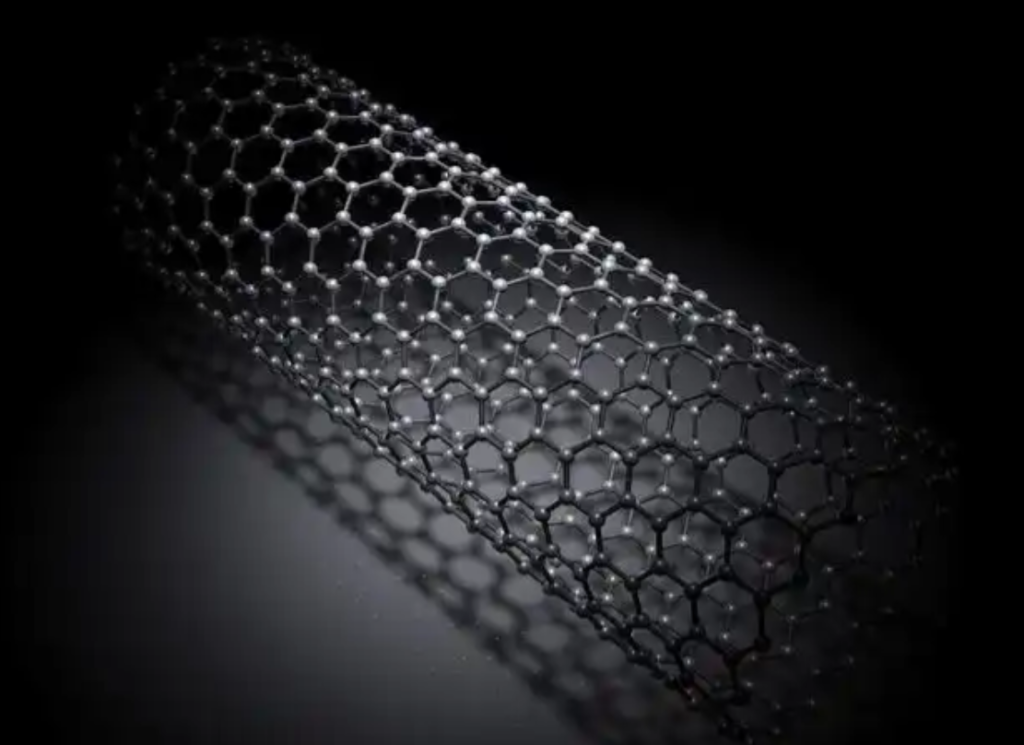

Advantages of Carbon Nanotubes in Li-S Batteries

-

Excellent Electrical Conductivity

CNTs form a conductive network within the cathode, enabling fast electron transfer even when sulfur’s intrinsic conductivity is low. -

High Surface Area

CNTs can host sulfur nanoparticles uniformly, ensuring efficient electrochemical reactions. -

Polysulfide Trapping

CNT surfaces, especially when functionalized, can physically confine or chemically anchor polysulfides, minimizing the shuttle effect. -

Mechanical Flexibility

CNT networks accommodate the volume expansion of sulfur during cycling, maintaining structural integrity. -

Lightweight

CNTs add minimal weight while significantly boosting performance—a critical factor for portable electronics and EVs.

Design Strategies Using CNTs

1. CNT-Sulfur Composite Cathodes

Sulfur can be impregnated into a CNT scaffold via melt-diffusion or solution methods. The interconnected CNT network ensures both electrical contact and polysulfide retention.

2. Functionalized CNTs

CNTs can be doped with nitrogen or oxygen-containing groups to enhance chemical bonding with polysulfides, effectively trapping them within the cathode.

3. CNT-Graphene Hybrid Structures

Combining CNTs with graphene sheets creates a 3D conductive framework with improved mechanical strength and sulfur-loading capacity.

4. CNT Interlayers

A CNT film placed between the cathode and separator can act as a secondary barrier to polysulfides while providing additional conductivity.

Recent Research Highlights

-

MIT & Stanford Collaboration: Developed nitrogen-doped CNT-sulfur cathodes with over 1,200 mAh/g capacity after 200 cycles.

-

Chinese Academy of Sciences: Created a CNT-graphene aerogel host for sulfur achieving 80% capacity retention after 500 cycles.

-

Samsung Advanced Institute of Technology: Investigated CNT-based interlayers reducing self-discharge in Li-S pouch cells.

Potential Applications

-

Electric Vehicles (EVs)

Li-S batteries with CNT-enhanced cathodes could dramatically increase driving range while lowering costs. -

Aerospace and Drones

High energy density and lightweight design make them ideal for aerospace missions and unmanned aerial vehicles. -

Grid Energy Storage

The use of abundant sulfur and CNT-reinforced stability can enable large-scale renewable energy storage solutions. -

Wearable Electronics

Flexible CNT-based Li-S batteries could power future foldable devices and smart textiles.

Challenges Ahead

-

Cost of CNTs: While prices have dropped, high-purity CNTs remain expensive compared to conventional carbon black.

-

Scalability: Large-scale, uniform integration of CNTs with sulfur is still technically demanding.

-

Safety: As with all lithium-based batteries, thermal stability and safety standards must be met before mass deployment.

With ongoing advances in CNT synthesis, functionalization, and large-scale composite fabrication, carbon nanotube-enabled Li-S batteries are likely to move from laboratory prototypes to commercial products within the next decade. Their combination of high energy density, environmental sustainability, and cost-effectiveness positions them as a game-changing technology for multiple industries.