Carbon Nanotubes in Smart Packaging Materials

Introduction

With the rapid advancement of smart manufacturing and the Internet of Things (IoT), traditional packaging materials are struggling to meet the high-efficiency demands of modern supply chains. The emergence of smart packaging technologies has driven the adoption of new materials, and carbon nanotubes (CNTs), with their exceptional mechanical properties, electrical conductivity, and chemical stability, have become an ideal enhancement for smart packaging solutions.

This article explores how carbon nanotubes contribute to material reinforcement, intelligent sensing, automation, and market potential in smart packaging.

1. The Role of Carbon Nanotubes in Smart Packaging

Carbon nanotubes are nanometer-scale tubular structures composed of carbon atoms, possessing extraordinary strength, conductivity, and durability, making them widely applicable in smart packaging:

- Superior Strength and Durability: Enhances packaging materials’ tear resistance and impact strength, making them ideal for protecting high-value products such as electronics and medical devices.

- Excellent Conductivity: Enables applications in anti-static packaging, protecting sensitive electronic components from electrostatic damage.

- High Thermal Stability: Withstands extreme temperatures, making it suitable for cold-chain logistics and specialized transportation needs.

- Chemical Resistance: Improves oxidation resistance and moisture protection, extending the shelf life of food, pharmaceuticals, and other packaged goods.

2. Key Applications of Carbon Nanotubes in Smart Packaging

(1) Reinforcement of Packaging Materials

Carbon nanotubes can be incorporated into polymer composites, enhancing the mechanical properties of packaging materials while maintaining lightweight features. Examples include:

- Food Packaging: Extends packaging durability, reducing food waste caused by packaging failure.

- Electronic Product Packaging: Provides superior shock resistance, preventing damage during transportation.

- Industrial Packaging: Enhances mechanical performance, making it ideal for heavy-duty or premium industrial products.

(2) Smart Sensing and Monitoring

Smart packaging requires real-time monitoring and data feedback, and the high conductivity of carbon nanotubes enables applications such as:

- Temperature Sensing: Monitors the storage conditions of food or pharmaceuticals, ensuring temperature stability in cold-chain logistics.

- Humidity Detection: Used in moisture-resistant packaging to prevent spoilage of food and pharmaceuticals.

- Pressure and Damage Monitoring: Smart packaging materials can detect internal damage and provide real-time feedback.

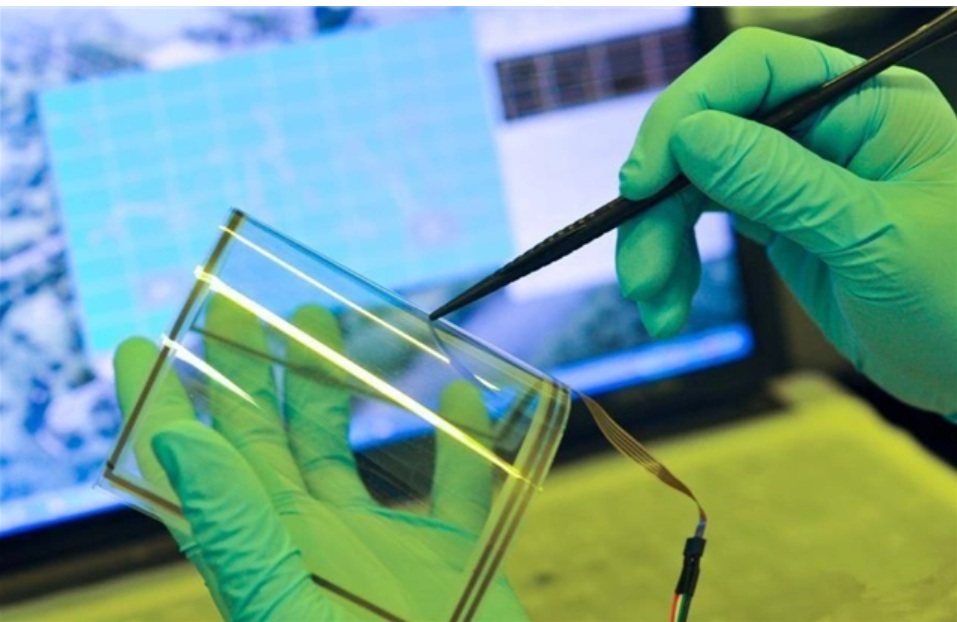

(3) Integration with Barcodes and RFID Technology

Carbon nanotubes are used in flexible electronic circuits, improving the durability and efficiency of barcodes and RFID tags:

- Smart Logistics Tracking: RFID tags enhanced with carbon nanotubes can be used for passive electronic labels, improving scan accuracy.

- Food Safety Traceability: Smart packaging can use barcodes or RFID systems to track production and transportation details, ensuring supply chain transparency.

- Anti-Counterfeiting Applications: Carbon nanotube-enhanced smart labels can be used for luxury goods and pharmaceuticals, preventing counterfeit products from entering the market.

(4) Enhancing Automation in Packaging Processes

The conductivity of carbon nanotubes makes them ideal for electrostatic discharge (ESD) protection materials, offering several advantages in automated packaging lines:

- Reduced Static Damage: Protects sensitive electronics from electrostatic discharge.

- Increased Automation Efficiency: Enhances barcode scanning and data transmission accuracy, accelerating automated packaging processes.

- Integration with Smart Factories: Combined with IoT technology, real-time monitoring and data management can be achieved.

3. Market Potential for Carbon Nanotube-Enhanced Smart Packaging

With the growth of smart manufacturing, e-commerce, pharmaceutical cold chains, and sustainable packaging, the demand for smart packaging continues to rise.

- Electronics Industry: Smart packaging can enhance the safety of electronic product logistics, driving market demand.

- Food and Pharmaceutical Industry: Increased demand for intelligent labels and temperature/humidity monitoring solutions is fueling market expansion.

- Premium Logistics and Anti-Counterfeiting: Anti-counterfeiting packaging and smart tracking technologies are providing security for high-value products.

Market research indicates that the smart packaging sector is expected to experience rapid growth over the next five years, with carbon nanotube materials playing a key role in driving innovation.

Conclusion

Carbon nanotubes, with their exceptional mechanical strength, electrical conductivity, and intelligent sensing capabilities, offer tremendous potential in smart packaging materials. They not only enhance the durability and protection of packaging but also enable smart monitoring, tracking, and anti-counterfeiting functions.

As smart manufacturing, IoT, and sustainable packaging continue to evolve, carbon nanotube-based smart packaging technologies will play an increasingly significant role in industries such as electronics, food & pharmaceuticals, and logistics, improving efficiency and security across the supply chain.