Carbon Nanotubes in Structural Composites: Strength Without the Weight

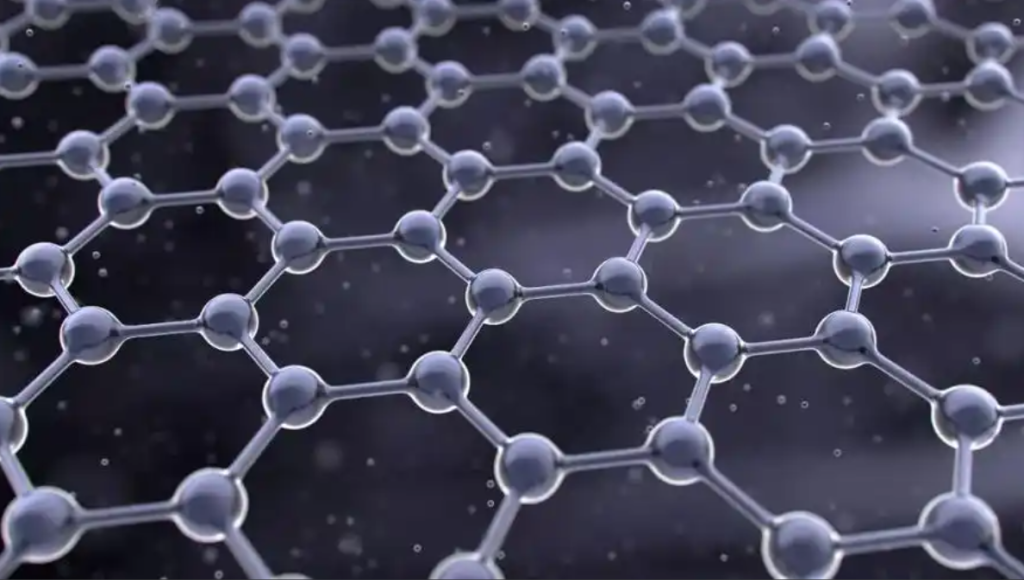

From aerospace engineering to sports equipment, the demand for lightweight yet high-strength materials is growing rapidly. Traditional composites like fiberglass and carbon fiber have made significant contributions, but carbon nanotubes (CNTs) are setting a new benchmark for structural performance.

With tensile strengths over 100 times that of steel and a density one-sixth as much, CNT-reinforced composites are enabling engineers to design lighter, stronger, and more resilient structures than ever before.

Why Carbon Nanotubes for Composites?

Carbon nanotubes bring a unique combination of properties that are particularly beneficial for structural applications:

-

Exceptional Strength: Tensile strength exceeding 60 GPa in individual tubes.

-

Lightweight: Density around 1.3–1.4 g/cm³, much lower than metals.

-

High Modulus: Excellent stiffness for load-bearing applications.

-

Electrical & Thermal Conductivity: Useful for multi-functional composites.

-

Nano-Scale Reinforcement: Even small additions significantly improve composite performance.

Applications Across Industries

1. Aerospace and Aviation

-

Challenge: Reducing aircraft weight without compromising safety.

-

CNT Solution: CNT-reinforced polymer composites reduce structural weight by up to 20%, leading to lower fuel consumption and extended flight range.

-

Example: Experimental UAV frames made with CNT composites have demonstrated both weight reduction and increased durability.

2. Automotive Lightweighting

-

Electric Vehicles (EVs) demand lighter frames for extended range.

-

CNTs can reinforce thermoplastics used in body panels, chassis parts, and interior components.

-

Improved impact resistance and fatigue life make CNT composites suitable for safety-critical components.

3. Sports and Recreation

-

High-performance bicycles, tennis rackets, and golf clubs benefit from CNT-enhanced stiffness and vibration damping.

-

Cyclists report better acceleration and handling due to weight savings without loss of strength.

4. Construction and Infrastructure

-

CNT-reinforced concrete and polymer composites can significantly increase load-bearing capacity and resistance to environmental degradation.

-

Bridges, towers, and offshore structures are potential beneficiaries.

How CNTs Enhance Composite Performance

-

Nano-Scale Reinforcement

-

CNTs distribute loads more efficiently than micro-scale fibers due to their enormous aspect ratio (length-to-diameter).

-

-

Crack Bridging and Arresting

-

CNTs can “bridge” microscopic cracks, preventing them from propagating and leading to catastrophic failure.

-

-

Improved Interfacial Bonding

-

Functionalizing CNT surfaces allows them to bond more strongly with polymer matrices, enhancing mechanical performance.

-

Manufacturing Techniques

-

Solution Blending: Dispersing CNTs in a polymer solution for film or coating applications.

-

Melt Mixing: Incorporating CNTs into molten thermoplastics for injection molding.

-

Prepreg Layups: CNT-infused resin systems applied to woven fabrics for aerospace-grade composites.

Challenges in Adoption

-

Dispersion: CNTs naturally tend to bundle, which can reduce their reinforcing potential.

-

Cost: High-quality CNTs are still expensive compared to other fillers.

-

Scaling: Producing uniform composites at industrial scale remains a challenge.

Future Prospects

The next phase of CNT composite development may focus on:

-

Hybrid Reinforcement: Combining CNTs with carbon fibers for hierarchical composites.

-

Smart Structures: Embedding CNT sensors into load-bearing components for real-time health monitoring.

-

Mass Market Penetration: As CNT production costs drop, automotive and consumer goods sectors will adopt them more widely.

Carbon nanotube-reinforced composites are redefining what’s possible in material engineering. By offering unmatched strength-to-weight ratios, durability, and multi-functionality, they are paving the way for a new generation of high-performance, lightweight structures.