Carbon Nanotubes in Structural Fibers: Strength, Conductivity, and Beyond

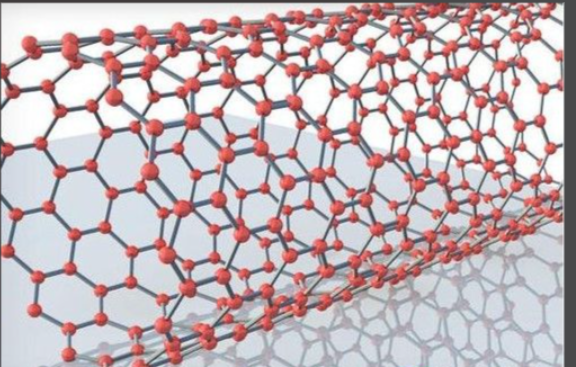

The demand for stronger, lighter, and smarter materials continues to accelerate in aerospace, defense, construction, and wearable electronics. Carbon nanotubes (CNTs), with their extreme mechanical strength, high aspect ratio, and tunable electrical/thermal conductivity, have become key building blocks in next-generation structural and multifunctional fibers.

This article explores how CNTs are enhancing fibers for structural reinforcement, energy storage, EMI shielding, and smart textiles.

🔹 1. The Power of CNTs in Fibers

CNTs exhibit:

-

Tensile strength up to 100 GPa

-

Young’s modulus ~1 TPa

-

Thermal conductivity ~3000 W/m·K

-

Electrical conductivity >10⁶ S/m

When incorporated into fibers, CNTs:

-

Improve load transfer and crack resistance

-

Provide conductivity without metal wires

-

Enable new functions (e.g., sensing, actuation)

🔹 2. Types of CNT-Reinforced Fibers

a. Spun CNT Yarns

-

Bundles of aligned CNTs twisted into fibers

-

Lightweight, strong, and conductive

-

Applications: space tethers, cables, e-textiles

b. Polymer–CNT Composite Fibers

-

CNTs embedded into polymer matrices (e.g., epoxy, PEEK, nylon)

-

Improve mechanical properties and thermal resistance

-

Used in aerospace composites, bulletproof vests, wind turbine blades

c. Hybrid Fibers with Carbon or Glass

-

CNTs coating or interweaving with traditional fibers

-

Boost bonding strength and provide functional surfaces

-

Reduce weight and increase fatigue life

🔹 3. Emerging Applications

✅ Aerospace and Automotive Structures

CNT fibers reinforce composites in:

-

Aircraft fuselage panels

-

Lightweight interior parts

-

Car bumpers and hoods

✅ Result: 20–40% weight reduction while maintaining or exceeding strength of conventional carbon fiber.

✅ Smart Textiles

CNTs provide:

-

Conductive pathways for sensors

-

Heating elements for active wear

-

Energy harvesting (e.g., triboelectric fabrics)

✅ Energy-Storing Fibers

Developments in CNT–supercapacitor fibers enable wearable energy storage integrated into clothing.

✅ EMI Shielding and Thermal Interfaces

CNT fiber fabrics offer:

-

Shielding against electromagnetic interference (for avionics or wearable electronics)

-

Heat dissipation in confined electronics

🔹 4. Processing Methods

-

Wet spinning: For dispersing CNTs in polymer dope

-

Dry spinning: Alignment and twisting of CNT arrays

-

Electrospinning: Creates nanoscale polymer–CNT fibers

-

In situ polymerization: Functionalized CNTs initiate polymer formation around them

🔹 5. Functionalization and Surface Treatment

Functional groups (e.g., –COOH, –NH₂) improve:

-

Interfacial adhesion with matrix

-

Dispersion in polymer

-

Integration with other nanomaterials (e.g., graphene, MXene)

🔹 6. Challenges and Commercial Prospects

| Challenge | Strategy |

|---|---|

| CNT dispersion | Ultrasonic treatment, surfactants |

| Scaling fiber spinning | Roll-to-roll alignment systems |

| Cost | Use of multi-walled CNTs or hybrids |

| Health & safety | Safe encapsulation in matrix |

Global market for CNT composite fibers is expected to grow beyond USD 3 billion by 2030, fueled by demand in aerospace, smart fabrics, and high-performance structures.

Carbon nanotubes are transforming the fiber industry with unprecedented mechanical, thermal, and electrical performance. From space-grade tethers to wearable electronics, CNTs enable multifunctionality in structural materials. With continuing breakthroughs in fabrication and scaling, these advanced fibers are poised to reshape everything from architecture to fashion.