Carbon Nanotubes in Transparent Conductive Films: A Replacement for ITO

Transparent conductive films (TCFs) are crucial components in modern electronics, serving as essential layers in touchscreens, displays, and flexible electronics. Traditional TCFs rely heavily on indium tin oxide (ITO), which, despite its widespread use, faces limitations such as brittleness, high production costs, and limited supply of indium. Carbon nanotubes (CNTs), with their outstanding electrical conductivity, flexibility, and transparency, are emerging as a promising alternative to ITO in transparent conductive films.

This article explores the use of CNTs in TCFs, their advantages, practical applications, and challenges, along with insights into market trends and future developments.

How CNTs Are Used in Transparent Conductive Films

Carbon nanotubes, particularly single-walled carbon nanotubes (SWCNTs), can be assembled into thin, interconnected networks on substrates to form transparent and conductive films. These films function as electrodes by enabling electrical conductivity while maintaining high optical transparency, making them suitable for applications like displays, touch sensors, and solar cells.

Common Fabrication Methods:

- Spray Coating: CNT solutions are sprayed onto a substrate to form a thin, conductive film.

- Spin Coating: A CNT solution is spread over the substrate and spun at high speeds to achieve a uniform layer.

- Layer-by-Layer Assembly: CNTs are deposited in controlled layers for improved transparency and conductivity balance.

- Printing Techniques: Inkjet or screen printing applies CNT-based inks directly onto flexible or rigid substrates.

Advantages of CNT Transparent Conductive Films

1. Flexibility and Durability

Unlike ITO, which is brittle and prone to cracking, CNT films exhibit exceptional mechanical flexibility and can bend, stretch, or fold without losing conductivity. This makes them ideal for flexible electronics and wearable devices.

2. High Electrical Conductivity

CNT networks have high intrinsic conductivity, with sheet resistances as low as 30–100 Ω/sq while maintaining over 90% transparency, comparable to or exceeding ITO in certain cases.

3. Abundant and Sustainable

CNTs are synthesized from abundant carbon-based precursors, avoiding the supply constraints and environmental issues associated with indium mining.

4. Lightweight and Thin

CNT films add minimal weight and thickness, a key factor in designing compact and lightweight electronic devices.

5. Compatibility with Flexible Substrates

CNTs adhere well to various substrates, including plastics, polymers, and flexible glass, enabling their use in roll-to-roll manufacturing processes for large-scale production.

Applications of CNT-Based Transparent Conductive Films

1. Touchscreen Displays

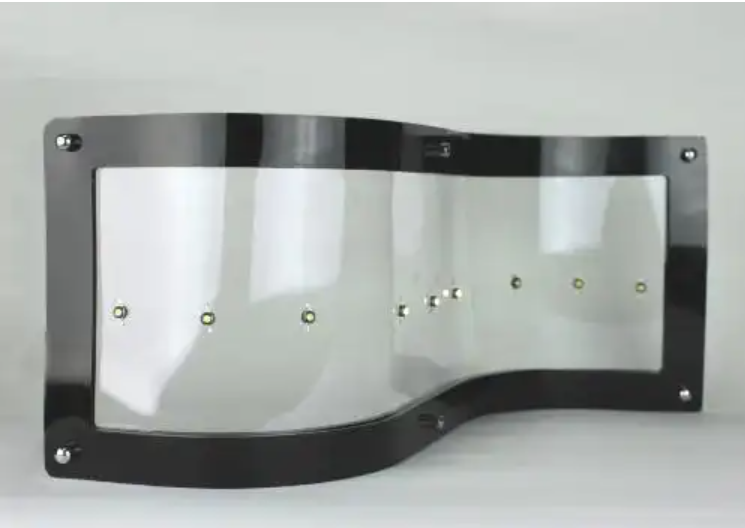

CNT TCFs replace ITO electrodes in touch panels, particularly in curved or flexible screens used in smartphones, tablets, and automotive interfaces.

2. Flexible Electronics

CNT TCFs are used in flexible displays, e-paper, and wearable devices, allowing seamless operation under bending or deformation.

3. OLED Displays and Lighting

The high transparency and conductivity of CNT films make them suitable for organic light-emitting diode (OLED) displays and lighting panels.

4. Solar Cells

CNT-based TCFs serve as transparent electrodes in photovoltaic cells, particularly in organic and perovskite solar cells, enhancing energy conversion efficiency and reducing production costs.

5. Transparent Antennas

CNT TCFs are employed in transparent antennas for wireless communication, including smart windows and IoT devices.

Case Studies and Practical Examples

1. Samsung Flexible Displays

Samsung has investigated CNT films for flexible AMOLED displays, leveraging their durability and conductivity in curved screen designs.

2. CNT-Silver Nanowire Hybrid Films

Companies like C3Nano have developed hybrid CNT-silver nanowire films, combining the properties of CNTs with nanowires to achieve superior conductivity and flexibility, used in next-generation touchscreens.

3. Solar Window Integration

CNT TCFs have been integrated into smart solar windows that combine energy generation with transparency for building-integrated photovoltaics (BIPVs).

Challenges in Using CNTs for Transparent Conductive Films

1. Dispersion and Uniformity

CNTs tend to aggregate due to strong van der Waals forces, leading to uneven films and reduced transparency. Techniques like surfactant use or functionalization improve dispersion but add complexity.

2. Sheet Resistance vs. Transparency Tradeoff

Balancing conductivity and transparency remains a challenge. Increasing CNT density improves conductivity but can reduce transparency. Optimized fabrication techniques are needed to address this tradeoff.

3. Cost of Production

Although cheaper than ITO in the long run, the high cost of producing high-purity SWCNTs limits their immediate adoption in cost-sensitive markets.

4. Stability and Scalability

CNT TCFs may degrade under harsh environmental conditions, and large-scale production with consistent quality requires further development.

5. Market Competition

CNT TCFs face competition from other emerging materials like silver nanowires, graphene, and conductive polymers, each with its own advantages and challenges.

Market Trends and Growth Potential

The market for CNT-based transparent conductive films is poised for substantial growth due to the increasing demand for flexible and wearable electronics.

Market Insights:

- The global TCF market is projected to reach USD 8 billion by 2030, with CNTs capturing a growing share.

- Asia-Pacific dominates the market due to the presence of major electronics manufacturers in countries like China, Japan, and South Korea.

Key Players:

- Tortech Nanofibers: Focused on CNT-based solutions for electronic applications.

- Nanocyl and Arkema: Leaders in CNT material production and integration.

- Cambrios and C3Nano: Innovators in hybrid TCF technologies combining CNTs with other nanomaterials.

Future Prospects

1. Hybrid Materials

Combining CNTs with materials like graphene or silver nanowires can overcome individual limitations and achieve better performance.

2. Roll-to-Roll Manufacturing

Developing scalable and cost-effective manufacturing processes will enable mass production of CNT TCFs, driving down costs and accelerating adoption.

3. Enhanced Environmental Stability

Coating CNT films with protective layers or functionalizing them for better chemical resistance can expand their use in harsh environments.

4. Integration with Emerging Technologies

CNT TCFs are expected to play a crucial role in upcoming technologies, such as foldable smartphones, augmented reality (AR) glasses, and stretchable electronics.

Conclusion

Carbon nanotubes offer a transformative solution to the limitations of traditional ITO in transparent conductive films. With their unique combination of flexibility, conductivity, and sustainability, CNT-based TCFs are well-positioned to drive innovation in touchscreens, displays, and flexible electronics.

While challenges related to cost, scalability, and performance optimization remain, ongoing research and advancements in fabrication techniques hold the promise of widespread adoption. As the electronics industry continues to demand more flexible, efficient, and sustainable materials, CNTs are set to become a cornerstone of next-generation transparent conductive films.