Carbon Nanotubes vs. Graphene: Technological Differences and Complementarity in Advanced Composite Materials

Introduction

Carbon nanotubes (CNTs) and graphene are two of the most studied nanomaterials in modern materials science. Both possess extraordinary mechanical, thermal, and electrical properties, making them invaluable in a range of applications. However, these materials differ significantly in structure and characteristics, and their combination in composite materials presents exciting opportunities for innovation. This article explores the technical differences between CNTs and graphene, their complementary properties, and recent advancements in composite technology that leverage their synergy.

Structural and Technical Differences

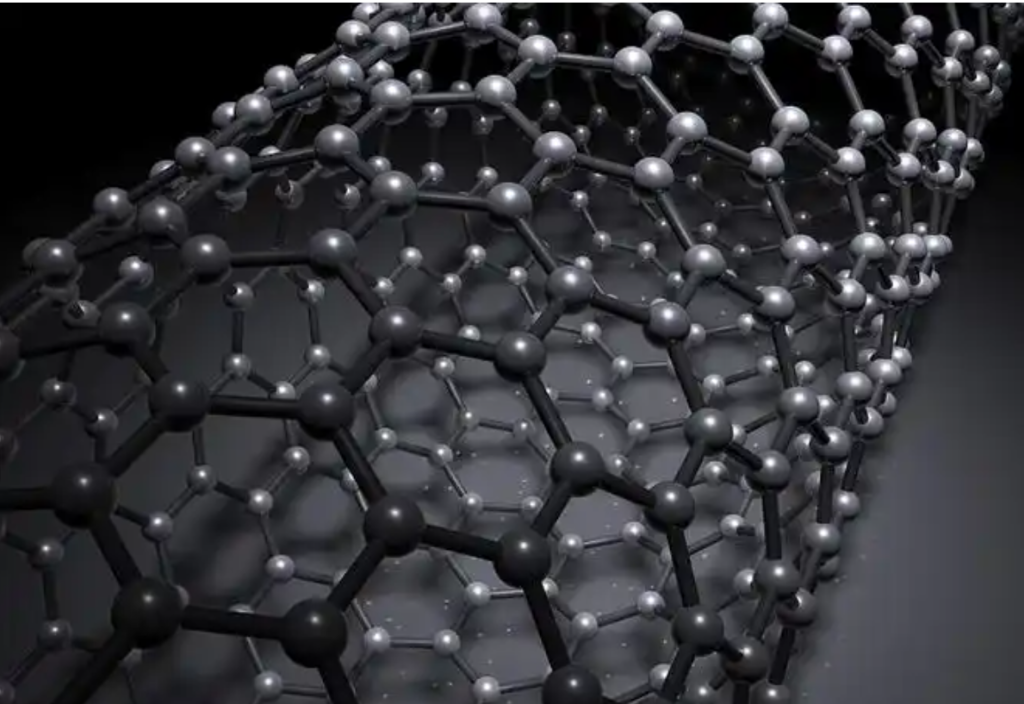

1. Carbon Nanotubes (CNTs)

CNTs are cylindrical nanostructures composed of rolled graphene sheets. They are classified into:

- Single-Walled Carbon Nanotubes (SWCNTs): Consist of a single graphene layer rolled into a tube with a diameter of 0.6 to 2 nm.

- Multi-Walled Carbon Nanotubes (MWCNTs): Comprise multiple concentric graphene tubes, with diameters ranging from 2 nm to hundreds of nanometers.

Key Properties:

- Mechanical Strength: High tensile strength and flexibility, suitable for reinforcing materials.

- Electrical Conductivity: Excellent conductivity, though dependent on chirality.

- Thermal Conductivity: Highly efficient heat transfer properties.

2. Graphene

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice.

Key Properties:

- Strength: Superior to CNTs in terms of in-plane tensile strength.

- Electrical Conductivity: Exceptional, with electrons moving almost unhindered.

- Thermal Conductivity: Highest known thermal conductivity among materials.

- Surface Area: Extremely high, beneficial for adsorption and surface reactions.

Complementarity in Properties

Combining CNTs and graphene in composite materials exploits their complementary properties:

- Mechanical Synergy:

- CNTs provide flexibility and reinforcement in the z-axis, while graphene enhances in-plane strength and stiffness.

- This combination results in isotropic composites with uniform strength across dimensions.

- Electrical Conductivity:

- CNTs serve as pathways for electron transport in the vertical direction, complementing graphene’s excellent in-plane conductivity.

- Applications: Conductive films, electrodes, and sensors.

- Thermal Management:

- Graphene efficiently dissipates heat in-plane, while CNTs provide vertical heat conduction.

- Applications: Thermal interface materials, electronics cooling systems.

- Surface Area and Interaction:

- Graphene’s large surface area enhances interaction with surrounding materials, while CNTs improve dispersion within composites.

- Applications: Catalysts, adsorbents, and battery materials.

Advances in Composite Technology

1. Hybrid Composites

Hybrid composites combining CNTs and graphene have demonstrated superior performance in strength, conductivity, and durability. Examples include:

- Polymer Composites: Enhanced mechanical and thermal properties for aerospace and automotive industries.

- Ceramic Composites: Improved toughness and resistance to thermal shock for high-temperature applications.

2. Energy Storage Applications

In supercapacitors and batteries, CNTs and graphene are combined to create electrodes with:

- High conductivity for efficient charge transfer.

- Large surface area for ion storage.

- Enhanced stability over multiple charge-discharge cycles.

3. Advanced Coatings

Graphene’s impermeability and CNT’s strength are used to create:

- Anti-corrosion Coatings: For protecting metals in harsh environments.

- EMI Shielding Materials: Effective in blocking electromagnetic interference.

4. Biomedical Innovations

CNTs and graphene composites are being explored for drug delivery and biosensors due to:

- Graphene’s biocompatibility and high surface area for molecule interaction.

- CNTs’ capability to penetrate cell membranes for targeted delivery.

Challenges and Future Directions

While the potential of CNT-graphene composites is vast, there are challenges to address:

- Dispersion: Achieving uniform dispersion in matrices to prevent agglomeration and ensure consistent performance.

- Scalability: Developing cost-effective methods for large-scale production.

- Interface Optimization: Improving the bonding between CNTs, graphene, and the matrix to maximize synergy.

Future Trends:

- Development of tailored functionalization techniques to improve compatibility with various matrices.

- Exploration of sustainable production methods to reduce environmental impact.

- Integration into next-generation devices, such as flexible electronics and advanced energy systems.

Conclusion

The combination of CNTs and graphene in composite materials offers unmatched advantages, driven by their complementary properties. Advances in hybrid materials are unlocking new possibilities across industries, from energy storage to biomedical engineering. As research continues to overcome challenges, CNT-graphene composites are poised to play a pivotal role in the next wave of material innovations.