CNT-Based Composites for Automotive Parts: Strength, Conductivity, and Lightweight Performance

The global automotive industry is undergoing a paradigm shift toward lightweight, energy-efficient, and high-performance vehicles. With the rise of electric vehicles (EVs), the need for advanced materials that combine strength, conductivity, and reduced weight has never been greater. Traditional materials such as steel and aluminum have limitations: they are heavy, prone to corrosion, and often lack the multifunctionality demanded by modern automotive engineering.

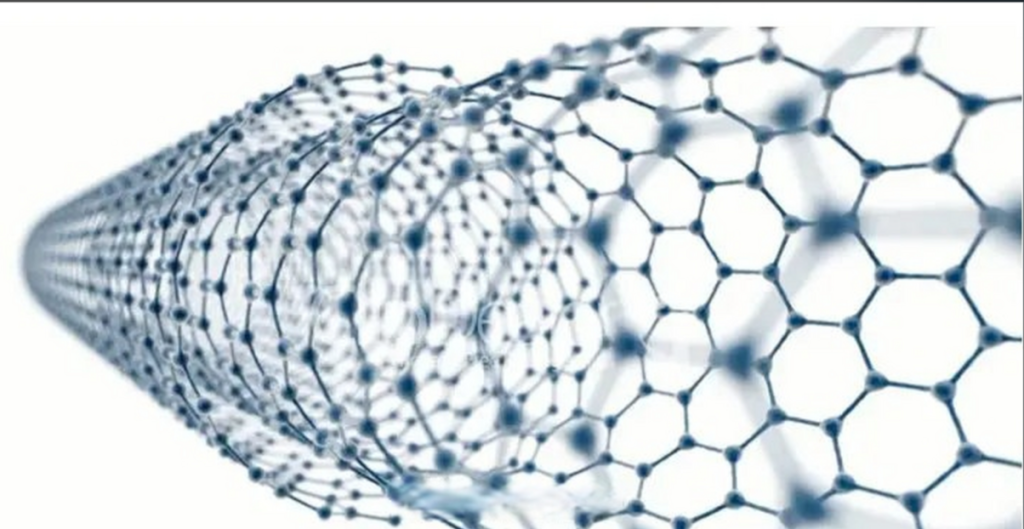

Carbon Nanotube (CNT)-based composites are emerging as a next-generation solution for automotive parts, offering a rare combination of mechanical reinforcement, electrical conductivity, and thermal stability. By integrating CNTs into polymers, metals, and ceramics, engineers can create components that withstand mechanical stress, manage heat, and support electronic integration—all while reducing vehicle weight.

Why CNTs for Automotive Applications?

1. Exceptional Strength-to-Weight Ratio

CNTs possess tensile strengths up to 100 times greater than steel, while being much lighter. When dispersed in polymer matrices, CNTs significantly increase stiffness and durability without adding extra mass.

2. Electrical Conductivity

Unlike conventional carbon fibers, CNTs provide intrinsic conductivity, allowing composites to double as structural and functional materials—for example, anti-static car parts or EMI-shielding panels.

3. Thermal Conductivity

CNTs enhance heat dissipation in components like battery housings, motor systems, and braking assemblies, improving safety and reliability.

4. Design Flexibility

CNT composites can be molded into complex geometries with relative ease, suitable for both interior and exterior automotive parts.

Key Automotive Applications of CNT Composites

1. Lightweight Structural Components

-

Body panels, bumpers, and chassis elements reinforced with CNT composites reduce overall weight.

-

A lighter car translates directly into higher fuel efficiency and extended EV driving range.

2. Battery and Energy Storage Components

-

CNT composites in battery housings and electrodes improve electrical pathways, heat management, and structural integrity.

-

Prevents thermal runaway risks in EV batteries.

3. Conductive Plastics for Interior/Exterior Parts

-

CNT-reinforced plastics used in dashboard panels, door trims, and exterior covers provide electrostatic discharge (ESD) protection and better durability.

4. Brake Systems

-

CNT composites enhance thermal resistance in brake pads and discs.

-

Reduce wear and deformation during high-temperature braking events.

5. Fuel and Fluid Systems

-

CNT-based polymer composites improve chemical resistance and conductivity, preventing static buildup in fuel lines and tanks.

6. Sensors and Embedded Electronics

-

CNT composites integrated into smart automotive parts enable strain sensing, temperature monitoring, and EMI shielding.

Case Studies and Industry Examples

-

CNT-Reinforced Polymer Bumpers

-

Research shows bumpers reinforced with CNT-polypropylene composites can reduce weight by 15–20% while maintaining crash resistance.

-

-

EV Battery Casings

-

CNT-filled composites used in casings improve thermal conductivity by 200–300%, helping prevent overheating during fast charging.

-

-

Brake Pad Development

-

Prototypes with CNT additives demonstrate longer wear life and reduced fade under high braking loads.

-

-

Fuel Line Applications

-

Automotive suppliers are already deploying CNT-polyamide composites in fuel lines to meet static discharge safety standards.

-

Advantages Over Traditional Materials

| Property | Steel/Aluminum | CNT Composites |

|---|---|---|

| Density | High | Low (lightweight) |

| Tensile Strength | Moderate–High | Ultra-high (up to 100x steel) |

| Electrical Conductivity | Metals: High, Polymers: Low | Tailorable with CNT loading |

| Thermal Conductivity | Moderate | High (efficient heat spread) |

| Corrosion Resistance | Limited (needs coating) | Excellent |

| Design Flexibility | Limited machining | Moldable, versatile |

Challenges and Considerations

-

Cost of CNT Production

-

High-purity CNTs remain expensive, limiting widespread automotive adoption.

-

-

Dispersion and Uniformity

-

Achieving even CNT distribution in matrices is technically challenging. Poor dispersion reduces mechanical and thermal benefits.

-

-

Scalability of Manufacturing

-

Automotive industry demands mass production at low cost, requiring scalable composite processing techniques.

-

-

Regulatory and Safety Aspects

-

Long-term safety and recyclability of CNT composites are still under investigation.

-

Future Outlook

As EVs and autonomous vehicles continue to rise, CNT composites are expected to expand across automotive sectors:

-

EV-Specific Applications: CNTs in battery modules, charging systems, and lightweight body panels.

-

Smart Car Parts: Integration of CNT composites with sensor functionalities for predictive maintenance.

-

Hybrid Materials: Combining CNTs with graphene or carbon fibers for optimized multi-functionality.

-

Sustainability: Future research may focus on bio-based CNT composites for greener automotive manufacturing.

By 2030, CNT composites are likely to be mainstream in high-end and electric vehicles, before diffusing into mass-market cars.

Carbon nanotube-based composites are unlocking new opportunities in automotive design, enabling lighter, stronger, and smarter vehicle parts. By enhancing mechanical, electrical, and thermal properties, CNT composites not only support energy efficiency and EV performance but also redefine the multi-functionality of automotive materials.

Although challenges such as cost and large-scale processing remain, ongoing advances in CNT production and composite engineering are paving the way for widespread adoption. In the race toward lighter, safer, and more sustainable vehicles, CNT composites are set to play a decisive role.