CNT-Based Electrodes for Sodium-Ion Batteries: Unlocking Affordable Energy Storage

As the world accelerates toward electrification, the demand for scalable and cost-effective energy storage has never been greater. While lithium-ion batteries (LIBs) dominate the market, concerns about lithium scarcity, cost, and uneven geographical distribution have spurred interest in alternatives. Among them, sodium-ion batteries (SIBs) stand out because sodium is abundant, inexpensive, and widely available.

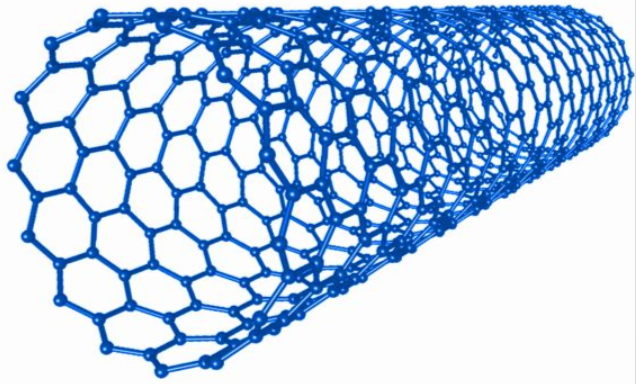

However, sodium-ion technology faces challenges in achieving high energy density, long cycle life, and stable electrode performance. This is where carbon nanotubes (CNTs) come in. Their unique electrical, mechanical, and structural properties make them ideal for improving sodium-ion battery electrodes, potentially unlocking the next generation of affordable energy storage.

Why Sodium-Ion Batteries?

-

Abundance: Sodium is over 1000 times more abundant than lithium.

-

Low Cost: Sodium salts are inexpensive, making SIBs a cost-effective choice for grid-scale storage.

-

Similar Chemistry: Sodium shares many electrochemical properties with lithium, enabling easier adaptation of LIB manufacturing lines.

Main challenges of SIBs include:

-

Larger ionic radius of Na⁺ (1.02 Å vs. 0.76 Å for Li⁺), causing slower diffusion and lattice strain.

-

Lower energy density compared to LIBs.

-

Electrode instability during charge–discharge cycles.

CNT-based electrodes provide solutions to these limitations.

Role of Carbon Nanotubes in SIB Electrodes

1. Enhanced Electrical Conductivity

CNTs are excellent conductors. When integrated into electrode materials, they improve electron transport, ensuring fast charge–discharge performance.

2. Structural Flexibility

CNTs provide a buffering network that accommodates the expansion and contraction caused by sodium-ion insertion, reducing electrode pulverization.

3. Large Surface Area

Their nanostructure offers a high surface-to-volume ratio, providing more active sites for sodium storage.

4. Hybrid Composites

CNTs combine well with metal oxides, phosphates, and carbonaceous materials, forming composite electrodes that balance conductivity, stability, and capacity.

CNTs in Anode Design

Sodium-ion battery anodes need to store Na⁺ efficiently while minimizing structural degradation. CNTs offer:

-

CNT-Silicon Composites: Silicon has high theoretical capacity but poor cycling stability. CNT networks improve mechanical integrity and conductivity.

-

CNT-Hard Carbon Hybrids: Hard carbon is the leading anode for SIBs. Embedding CNTs enhances sodium storage capacity and reduces resistance.

-

CNT-Coated Metal Oxides: Materials like Fe₂O₃ and SnO₂ achieve higher reversible capacity when stabilized with CNT frameworks.

CNTs in Cathode Design

Although cathode research in SIBs is less CNT-heavy, some advances include:

-

CNT-Coated Layered Oxides (NaMnO₂, NaNiMnO₂): CNT coatings enhance conductivity and stabilize surface reactions.

-

CNT-Polyanionic Materials (Na₃V₂(PO₄)₃): CNT integration boosts cycling stability and rate performance.

Case Studies & Research Progress

-

CNT/Hard Carbon Anodes

-

Studies show ~350 mAh/g capacity with improved cycling stability.

-

CNTs act as conductive bridges, preventing particle aggregation.

-

-

CNT-Metal Oxide Composites

-

Fe₂O₃-CNT composites demonstrate better rate capability and structural stability.

-

-

CNT-Supported Cathodes

-

CNT frameworks reduce electron transport resistance in layered oxide cathodes, extending cycle life.

-

Challenges & Considerations

-

Cost of CNT Production: Large-scale, low-cost synthesis of CNTs remains a bottleneck.

-

Uniform Dispersion: Ensuring CNTs are evenly distributed in composites is key to performance.

-

Scalability: Translating lab-scale CNT composites into industrial production requires process optimization.

CNT-based electrodes could help sodium-ion batteries become a serious competitor to lithium-ion technology, especially in grid storage, renewable integration, and electric mobility in cost-sensitive markets. With ongoing advances in scalable CNT production and electrode engineering, CNT-SIB hybrids may soon play a critical role in global energy storage infrastructure.