CNT-Based Transparent Conductive Films – Alternatives to ITO

In the rapidly evolving world of electronics and optoelectronics, the need for transparent conductive materials has grown significantly. These materials are crucial in devices like touchscreens, solar cells, OLED displays, and smart windows. For years, Indium Tin Oxide (ITO) has been the dominant material used for transparent conductive films due to its excellent electrical conductivity and optical transparency.

However, ITO comes with several disadvantages, including high cost, limited mechanical flexibility, and dependence on indium, a rare and expensive material. This has driven the search for viable alternatives. Among the most promising candidates are Carbon Nanotube (CNT)-based transparent conductive films, which offer a unique combination of high conductivity, flexibility, and sustainability.

This article delves into the technology behind CNT-based transparent conductive films, their advantages, and why they are emerging as a viable alternative to ITO.

1. What Are CNT-Based Transparent Conductive Films?

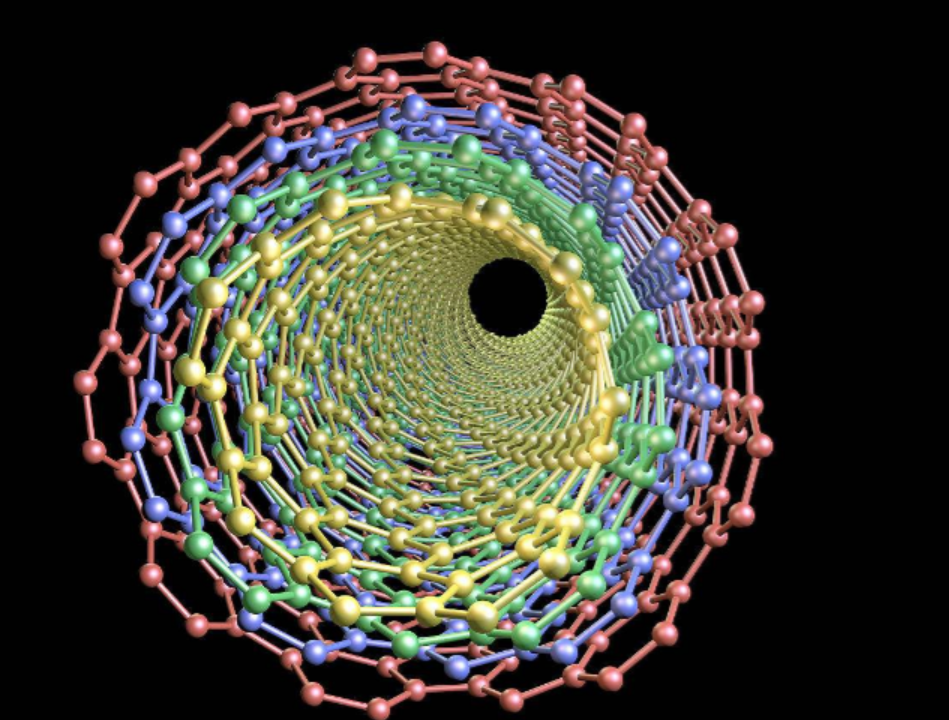

Carbon Nanotubes (CNTs) are cylindrical nanostructures made of carbon atoms arranged in a hexagonal lattice. CNTs are known for their exceptional mechanical strength, thermal conductivity, and electrical properties. When used in transparent conductive films, CNTs are typically dispersed in a polymer matrix or placed on a substrate such as glass or plastic to form a conductive network.

These films maintain the transparency required for optoelectronic devices while offering high electrical conductivity. CNT-based transparent conductive films are used as alternatives to ITO in applications such as touchscreens, solar cells, displays, and even transparent heaters.

2. How Do CNT-Based Transparent Conductive Films Work?

CNT-based transparent conductive films function through the conductive pathways formed by the network of carbon nanotubes. Here’s a breakdown of how they work:

2.1 CNT Dispersion and Film Formation

To create CNT-based transparent conductive films, CNTs are first dispersed in a solution (often a polymer matrix or solvent) to ensure even distribution. This dispersion forms a network of CNTs across the surface of a transparent substrate (such as glass or PET). The resulting film has both electrical conductivity and optical transparency.

2.2 Electrical Conductivity

The conductive properties of CNTs come from their high electron mobility and the long-range order of the nanotube network. When an electric field is applied across the film, electrons can travel efficiently through the CNT network, providing excellent electrical conductivity.

2.3 Transparency

The transparency of the CNT-based film is determined by the density of the CNT network. A sparse network allows more light to pass through, ensuring that the film remains optically transparent while still providing the required conductivity.

2.4 Flexibility

One of the standout features of CNT-based films is their flexibility. CNTs are incredibly strong and flexible, and when incorporated into a polymer matrix, the resulting film can be bent or stretched without compromising its electrical properties. This flexibility makes CNT-based films ideal for flexible electronics and wearable devices.

3. Advantages of CNT-Based Transparent Conductive Films

The shift from ITO to CNT-based films offers several compelling advantages. These advantages make CNT films an attractive alternative for a wide range of applications.

3.1 Cost-Effectiveness

One of the main drawbacks of ITO is its high cost, primarily due to the rarity and expense of indium. In contrast, carbon nanotubes are made from abundant carbon sources, making CNT-based films a more cost-effective option. Furthermore, the cost of fabrication for CNT-based films is also lower, which can significantly reduce overall production costs.

3.2 Flexibility and Stretchability

CNT-based films offer exceptional mechanical flexibility, which is a significant advantage over the brittle nature of ITO films. This flexibility enables the development of bendable displays, flexible solar panels, and wearable electronics. The stretchability of CNT-based films opens up possibilities for use in foldable devices, smart textiles, and bioelectronics.

3.3 Mechanical Strength

In addition to flexibility, CNTs also provide excellent mechanical strength. The high tensile strength of carbon nanotubes makes the films highly resistant to cracking, delamination, and abrasion. This is a crucial advantage, especially in applications where durability is important, such as consumer electronics and automotive displays.

3.4 High Transparency and Conductivity

CNT-based films can be engineered to achieve high optical transparency (often exceeding 90% in visible light) while maintaining excellent electrical conductivity. This makes them suitable for applications requiring both transparency and conductivity, such as touchscreens, OLED displays, and solar cells.

3.5 Environmental Sustainability

Carbon nanotubes are an attractive alternative to ITO from an environmental perspective. Unlike ITO, which relies on the extraction of rare and toxic elements, CNTs are made from carbon, a much more abundant and eco-friendly material. Additionally, CNT-based films are non-toxic and can be produced in a sustainable manner, reducing the environmental impact of electronics manufacturing.

4. Applications of CNT-Based Transparent Conductive Films

The unique properties of CNT-based transparent conductive films make them suitable for a wide range of advanced applications. Below are some of the most promising uses:

4.1 Touchscreen Displays

The use of CNT-based transparent conductive films in touchscreens allows for the development of more durable, flexible, and cost-effective devices. CNT films are capable of providing high transparency and conductivity, making them an ideal choice for both consumer electronics and industrial applications.

4.2 Solar Cells

In photovoltaic (PV) cells, CNT-based transparent conductive films are used as transparent electrodes to collect and transport charge. The low-cost, high-conductivity, and lightweight nature of CNT films make them an ideal choice for flexible solar panels and solar windows that require transparency as well as conductivity.

4.3 OLED Displays

CNT-based transparent conductive films can be used in OLED displays, where they serve as electrodes that enable the light-emitting layers to function. The flexibility and high conductivity of CNTs make them particularly useful for bendable or foldable OLED devices.

4.4 Transparent Heaters

The flexibility and high conductivity of CNT films make them ideal for use in transparent heating applications, such as smart windows or defrosting systems. CNT-based films can provide uniform heating while maintaining optical transparency, offering a practical solution for automotive and building applications.

4.5 Flexible and Wearable Electronics

CNT-based transparent conductive films are a perfect match for wearable electronics, such as smart textiles and fitness trackers. Their lightweight, flexible, and conductive properties make them ideal for integration into soft, stretchable devices that need to maintain high performance while being comfortable to wear.

5. Challenges and Future Directions

While CNT-based transparent conductive films offer numerous advantages, there are still some challenges that need to be addressed for widespread adoption:

5.1 Scalability and Manufacturing

Producing CNT-based films at large scales while maintaining consistent quality and performance can be challenging. The dispersion of CNTs in a uniform manner and film uniformity need to be optimized to meet the standards required for commercial applications.

5.2 Conductivity Optimization

While CNT-based films offer excellent conductivity, further optimization of the CNT network and film structure is needed to compete with the high-performance of ITO in certain applications. Enhancing the contact resistance between CNTs and substrates is an ongoing area of research.

5.3 Long-Term Durability

The long-term stability of CNT-based films under varying environmental conditions (e.g., temperature, humidity, UV exposure) needs to be thoroughly tested to ensure their durability and reliability in real-world applications.

CNT-based transparent conductive films present a promising alternative to traditional ITO films, offering superior flexibility, cost-effectiveness, and environmental sustainability. As the demand for flexible electronics and high-performance optoelectronics continues to grow, CNT-based films are poised to become a key material in the next generation of electronic devices.

While challenges remain in terms of scalability and long-term performance, ongoing research and development are expected to address these hurdles, making CNT-based transparent conductive films a viable and sustainable option for a wide range of applications in the near future.