CNT Composites for EMI Shielding – Mechanism and Material Design

1. Introduction: EMI Shielding as a System-Level Challenge

As electronic systems become more compact, faster, and more integrated, electromagnetic interference (EMI) has emerged as a critical design challenge across industries such as:

-

AI servers and data centers

-

Electric vehicles and power electronics

-

Industrial control systems

-

Aerospace and communication equipment

Traditional EMI shielding solutions rely on metals, which provide good shielding effectiveness but introduce drawbacks such as high weight, corrosion risk, and limited design flexibility.

CNT-based composites offer a lightweight, corrosion-resistant, and design-flexible alternative, enabling EMI shielding to be integrated directly into structural and functional components.

2. Fundamentals of EMI Shielding

EMI shielding performance is governed by three primary mechanisms:

-

Reflection – caused by mobile charge carriers

-

Absorption – conversion of electromagnetic energy into heat

-

Multiple internal reflections – energy dissipation within conductive networks

Effective shielding materials typically rely on electrical conductivity and network continuity, rather than bulk thickness alone.

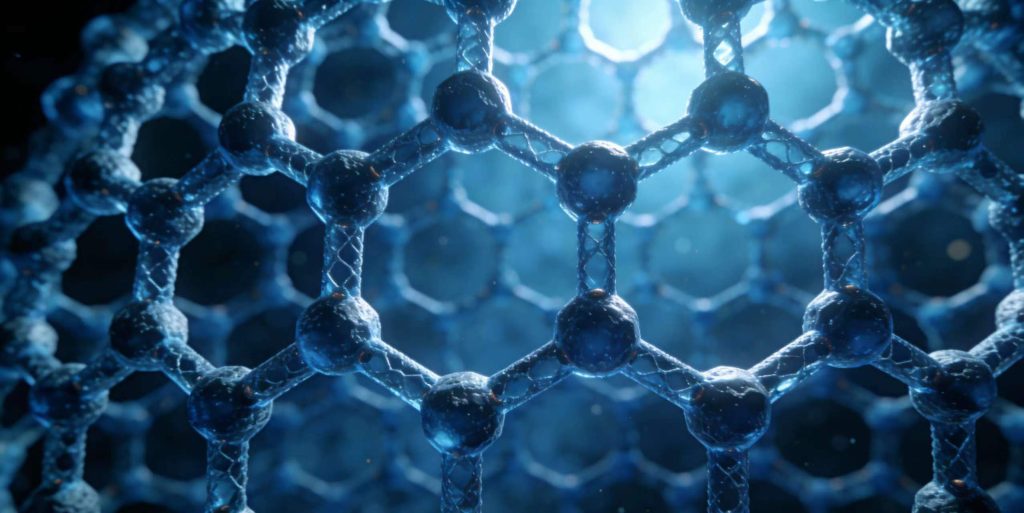

3. Why CNTs Are Effective for EMI Shielding

CNTs possess several intrinsic advantages:

-

High aspect ratio enables percolating conductive networks at low loading

-

Excellent electrical conductivity supports both reflection and absorption

-

Nanoscale dimensions promote multiple internal reflections

-

Low density compared to metal fillers

These characteristics make CNTs especially suitable for polymer-based EMI shielding composites.

4. EMI Shielding Mechanism in CNT Composites

4.1 Network-Based Conductivity

CNTs form interconnected conductive networks within polymer matrices, enabling:

-

Charge carrier mobility

-

Reflection of incident electromagnetic waves

Lower percolation thresholds mean effective shielding at reduced filler content.

4.2 Absorption-Dominant Shielding

Unlike metals, CNT composites often rely more on absorption than reflection:

-

CNT networks convert electromagnetic energy into heat

-

Reduces secondary electromagnetic pollution

This is particularly important in high-frequency and sensitive electronic environments.

4.3 Multiple Scattering and Attenuation

CNT networks create:

-

Numerous interfaces

-

Complex conductive pathways

These features enhance multiple internal reflections, further attenuating EMI.

5. Material Design Parameters

Effective CNT EMI shielding composites require careful material design:

5.1 CNT Type Selection

-

MWCNTs commonly used for cost-performance balance

-

SWCNTs used in thin or high-performance applications

5.2 CNT Loading Level

-

Must exceed percolation threshold

-

Excessive loading increases viscosity and cost

5.3 Dispersion Quality

-

Uniform dispersion is critical for network continuity

-

Agglomeration reduces shielding effectiveness

6. Polymer Matrix Considerations

CNTs can be integrated into various matrices:

| Matrix Type | Advantages |

|---|---|

| Thermoplastics | Injection molding, recyclability |

| Thermosets | Structural integrity, thermal stability |

| Elastomers | Flexibility, vibration tolerance |

| Coatings | Lightweight EMI shielding layers |

Matrix selection impacts processing, durability, and EMI performance.

7. CNT vs Traditional EMI Shielding Fillers

| Parameter | Metal Fillers | Carbon Black | CNT Composites |

|---|---|---|---|

| Density | High | Medium | Low |

| Percolation Threshold | N/A | High | Very low |

| Shielding Mechanism | Reflection-dominant | Limited absorption | Absorption + reflection |

| Corrosion Resistance | Poor | Good | Excellent |

| Design Flexibility | Low | Medium | High |

CNT composites offer a balanced approach between performance and design freedom.

8. Hybrid CNT-Based EMI Systems

Hybrid systems further enhance shielding:

-

CNT + graphene for planar + network conductivity

-

CNT + ferrites for magnetic loss enhancement

Hybrid architectures enable broadband EMI shielding with controlled material cost.

9. Application Areas

CNT EMI shielding composites are used in:

-

Electronic housings

-

AI server enclosures

-

EV battery modules

-

Industrial control cabinets

-

Communication equipment

Their ability to combine structural function with EMI control is a key advantage.

10. Processing and Manufacturing Considerations

Key factors include:

-

Shear conditions during compounding

-

Compatibility with existing molding processes

-

Viscosity management

-

Batch-to-batch consistency

Successful implementation depends on engineering integration, not just material selection.

11. Future Trends

-

Thinner EMI shielding layers

-

Multi-functional composites (EMI + thermal + structural)

-

Hybrid CNT–graphene systems

-

Application-specific CNT grades

CNT composites provide a lightweight, corrosion-resistant, and design-flexible solution for EMI shielding.

By leveraging:

-

Network-based conductivity

-

Absorption-dominant shielding mechanisms

-

Tunable material architectures

engineers can design EMI shielding materials optimized for performance, manufacturability, and lifecycle stability.