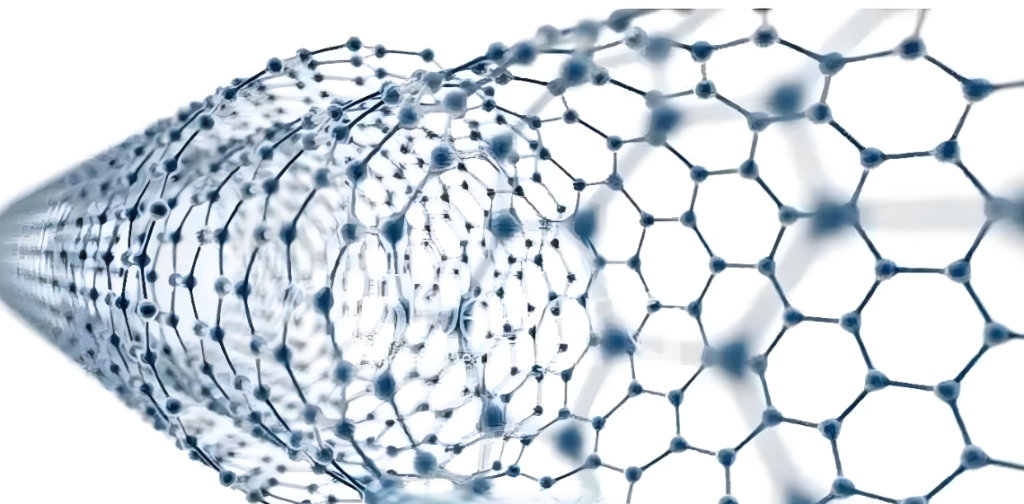

CNT Composites for EMI Shielding – Mechanism and Material Design

1. The Growing Need for EMI Shielding

With the increasing miniaturization and complexity of electronic devices, electromagnetic interference (EMI) has become a major concern for the performance, reliability, and longevity of electronic systems. Effective EMI shielding is essential to:

-

Protect sensitive electronics from external electromagnetic fields

-

Prevent electromagnetic emissions from interfering with surrounding devices

-

Ensure compliance with industry standards (e.g., FCC, CE)

While traditional metals offer effective EMI shielding, their limitations—such as weight, cost, and susceptibility to corrosion—are driving the development of alternative materials. Carbon nanotube (CNT)-based composites have emerged as a promising solution, offering excellent electrical conductivity and mechanical properties, making them ideal for lightweight, durable, and efficient EMI shielding materials.

2. Key Mechanisms of EMI Shielding

EMI shielding is achieved primarily through three mechanisms:

-

Reflection – The shielding material reflects the incoming electromagnetic waves. This is driven by the material’s electrical conductivity.

-

Absorption – The material absorbs and dissipates the energy of the waves, converting it into heat.

-

Multiple internal reflections – The material may cause electromagnetic waves to reflect and scatter internally, further reducing their intensity.

For CNT composites, conductivity and network connectivity are the most critical parameters for all three shielding mechanisms.

3. Why CNT Composites Are Ideal for EMI Shielding

Carbon nanotubes exhibit unique properties that make them highly effective for EMI shielding:

-

High electrical conductivity – CNTs have exceptional electrical properties, with high electron mobility, making them effective at reflecting and absorbing electromagnetic waves.

-

Mechanical strength – CNTs provide excellent reinforcement to the composite, improving the mechanical durability of the shielding material.

-

Lightweight – Unlike metals, CNT composites are lightweight, which is ideal for portable and space-constrained applications.

-

Corrosion resistance – CNT composites offer superior corrosion resistance compared to metals, making them more reliable in harsh environmental conditions.

-

Scalable – CNT composites can be easily scaled up for mass production, offering a cost-effective alternative to traditional metals.

4. Mechanism of EMI Shielding in CNT Composites

4.1 Conductivity and Reflection

The electrical conductivity of CNT composites enables the reflection of incoming electromagnetic waves. The conductive CNT network forms continuous pathways for charge carriers, allowing for the effective reflection of EMI. The shielding effectiveness increases as the CNT loading increases, but at the cost of viscosity and processability.

4.2 Absorption and Dissipation

CNTs can also absorb a significant portion of the electromagnetic waves. When electromagnetic waves penetrate the material, the high surface area and network structure of CNTs facilitate energy absorption and heat dissipation. This mechanism is particularly beneficial for high-frequency EMI.

4.3 Multiple Internal Reflections

CNTs can create multiple internal reflections within the material due to their high aspect ratio and network structure. These internal reflections enhance the attenuation of electromagnetic waves, leading to improved shielding performance.

5. Material Design for CNT Composites in EMI Shielding

Designing effective CNT-based EMI shielding materials requires careful consideration of the following factors:

5.1 CNT Type and Form

-

Single-Walled CNTs (SWCNTs) – Offer superior conductivity but are typically more expensive and harder to disperse in the matrix.

-

Multi-Walled CNTs (MWCNTs) – Easier to process and generally more cost-effective, making them suitable for large-scale production.

In many cases, MWCNTs are preferred due to their excellent combination of electrical conductivity, mechanical properties, and ease of processing.

5.2 Loading Level

-

The percolation threshold is the point at which the CNT network becomes continuous and begins to conduct electricity effectively.

-

Low CNT loading results in insufficient conductivity, while excessive loading can cause poor processability, reduced mechanical properties, and increased material cost.

Typically, 2–5 wt.% CNT loading is ideal for balancing performance and manufacturability.

5.3 Dispersion Quality

CNT dispersion is critical to the material’s final properties. Poor dispersion leads to agglomeration, which disrupts the continuity of the conductive network, resulting in poor shielding performance. Proper dispersion techniques, such as sonication or surface functionalization, must be used to ensure uniform distribution.

6. Polymer Matrix Selection for CNT EMI Composites

CNTs are often incorporated into a polymer matrix to improve processability and provide structural support. Common matrix materials include:

-

Thermoplastics (e.g., ABS, Nylon, Polycarbonate) – Offer good processability and mechanical strength. Suitable for lightweight EMI shielding applications.

-

Thermosets (e.g., Epoxy, Polyester) – Provide better thermal and chemical resistance. Suitable for more demanding EMI shielding applications.

-

Elastomers (e.g., Silicone, TPU) – Offer flexibility and impact resistance, ideal for applications requiring mechanical resilience.

The matrix choice must match the application environment and processing requirements.

7. Performance Comparison: CNT vs. Traditional EMI Shielding Materials

| Property | Traditional Metal Shielding | CNT-Based Composites |

|---|---|---|

| Density | High | Low |

| Electrical Conductivity | Excellent | Good to Excellent |

| Corrosion Resistance | Low | High |

| Weight | Heavy | Lightweight |

| Cost | High | Medium |

| Processability | Challenging | Easy (with dispersion) |

| Design Flexibility | Low | High |

CNT composites offer a balanced solution for EMI shielding, particularly in weight-sensitive and corrosion-prone environments.

8. Applications of CNT-Based EMI Shielding

CNT composites are well-suited for various industries and applications, including:

-

Automotive and Electric Vehicles (EVs) – For shielding electronic components in a compact, lightweight design.

-

Consumer Electronics – For effective EMI shielding in devices such as smartphones, laptops, and wearables.

-

Telecommunications – For use in housings and enclosures for communication equipment, where high-performance shielding is required.

-

Aerospace – For shielding sensitive avionics and electrical systems in harsh environments.

-

Medical Devices – For shielding sensitive medical electronics from EMI.

9. Manufacturing and Processing Considerations

To effectively produce CNT-based EMI shielding composites, consider the following processing techniques:

-

Injection Molding – Suitable for high-volume production of complex parts.

-

3D Printing – Can create customized, geometrically complex EMI shielding structures.

-

Extrusion – Ideal for producing films, sheets, or fibers for large-scale applications.

CNT-based composites represent a promising solution for EMI shielding, offering:

-

High conductivity and excellent absorption capabilities

-

Superior mechanical properties and corrosion resistance

-

Lightweight and scalable manufacturing processes

By carefully selecting the CNT type, loading level, and matrix material, engineers can design highly efficient EMI shielding materials that meet the needs of modern electronic systems.