CNT Conductive Paste and Ink – For Printed and Flexible Electronics

As flexible electronics and printed devices move from laboratories to mass production, the need for lightweight, reliable, and flexible conductive materials has grown rapidly.

Among various nanomaterials, Carbon Nanotube (CNT)-based conductive pastes and inks are emerging as one of the most versatile solutions for printed electronics, sensors, and energy devices.

This article explores how CNT conductive paste and ink are formulated, how they differ from traditional materials, and what advantages they bring to the growing field of flexible and printed electronics.

1. Introduction to CNT Conductive Materials

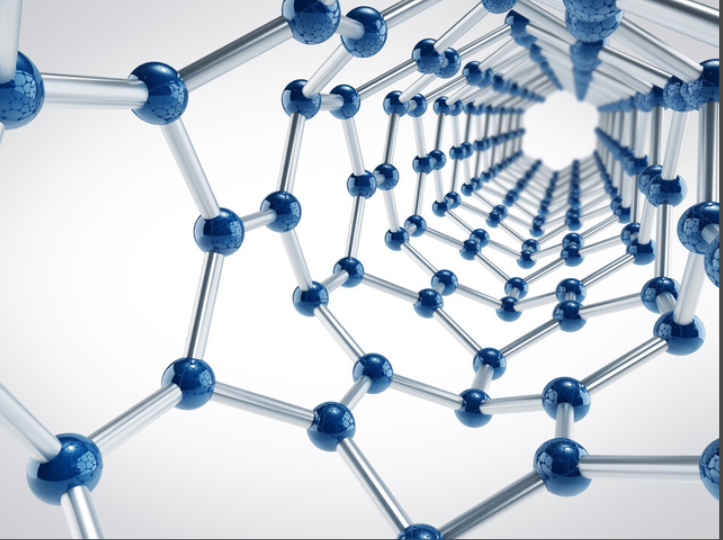

Carbon nanotubes (CNTs) are one-dimensional nanostructures composed of rolled graphene sheets. Depending on their structure, CNTs can be single-walled (SWCNTs) or multi-walled (MWCNTs), offering exceptional electrical, thermal, and mechanical properties.

Key Properties

-

Electrical conductivity: Up to 10⁶ S/m

-

Thermal conductivity: > 3,000 W/m·K

-

Mechanical strength: ~100× stronger than steel by weight

-

Flexibility and elasticity: Can bend without breaking

These unique characteristics make CNTs ideal for use in conductive pastes and inks, where they serve as the active filler replacing or complementing metallic particles (e.g., silver, copper).

2. What Is CNT Conductive Paste or Ink?

CNT conductive paste or ink is a dispersion of carbon nanotubes within a binder and solvent system that allows it to be printed, coated, or sprayed onto various substrates.

After drying or curing, the CNT network forms a continuous conductive film that maintains flexibility and stability even under bending or stretching.

Basic Components

| Component | Function |

|---|---|

| CNT filler | Provides electrical and mechanical conductivity |

| Binder/resin | Ensures adhesion and film formation |

| Solvent/dispersant | Adjusts viscosity for printing and prevents CNT aggregation |

| Additives | Control rheology, curing, or surface energy |

The formulation is typically customized for the chosen printing method and target performance requirements.

3. Printing and Deposition Methods

CNT conductive inks and pastes can be adapted to a wide range of printing technologies, making them highly suitable for flexible electronics manufacturing.

3.1 Screen Printing

-

Common for large-area conductive patterns such as antennas, heaters, and electrodes.

-

CNT pastes are optimized for high viscosity and precise edge definition.

-

Works well on flexible substrates like PET, PEN, or PI films.

3.2 Inkjet Printing

-

Enables high-resolution patterning for sensors, thin-film transistors, or biomedical electrodes.

-

Requires finely dispersed CNTs (<100 nm aggregates) to avoid nozzle clogging.

-

Water- or alcohol-based dispersions are commonly used for environmental compatibility.

3.3 Spray and Slot-Die Coating

-

Suitable for uniform conductive coatings on large surfaces.

-

Used in transparent films, EMI shielding, and energy devices.

3.4 Flexographic and Gravure Printing

-

Allow high-speed roll-to-roll production, ideal for commercial flexible electronics lines.

4. Electrical and Mechanical Performance

The performance of CNT conductive films depends on several interrelated factors: CNT type, dispersion quality, and film structure.

4.1 Electrical Conductivity

Typical CNT inks achieve sheet resistance values between 10–500 Ω/sq, depending on thickness and CNT loading.

While lower than pure silver inks, CNT coatings excel in stability, flexibility, and environmental resistance.

4.2 Flexibility and Bending Stability

CNT networks can stretch, twist, and fold without significant performance degradation.

In bending tests, resistance change after 10,000 cycles is often <5%, far outperforming metallic inks that easily crack or delaminate.

4.3 Thermal Conductivity

CNT films also provide efficient heat dissipation, which is valuable in high-power printed circuits and heaters.

4.4 Transparency and Thinness

CNT inks can form semi-transparent conductive films with >85% optical transmittance, useful for touch panels and display electrodes.

5. Comparison: CNT vs. Traditional Conductive Materials

| Property | CNT Ink/Paste | Silver Ink | Carbon Black Ink |

|---|---|---|---|

| Electrical Conductivity | High (10³–10⁶ S/m) | Very high (10⁷ S/m) | Moderate (10²–10³ S/m) |

| Flexibility | Excellent | Poor–moderate | Good |

| Thermal Conductivity | High | Moderate | Low |

| Corrosion Resistance | Excellent | Poor (oxidation) | Excellent |

| Transparency | Optional | Opaque | Opaque |

| Cost Stability | Stable | Price-sensitive (metal-based) | Low |

| Suitable for Roll-to-Roll | Yes | Limited | Yes |

Although silver inks remain dominant for high-conductivity applications, CNT-based pastes are gaining ground where flexibility, stability, and cost control are more critical.

6. Industrial Applications

CNT conductive inks and pastes have found broad applications across several industries, especially in areas where flexible, lightweight, or transparent conductors are needed.

6.1 Flexible Printed Circuits (FPC)

CNT inks can replace or complement traditional metal conductors in flexible circuit boards used in:

-

Wearable devices

-

Flexible displays

-

Portable sensors

They offer improved fatigue resistance and mechanical durability under continuous bending.

6.2 Printed Sensors

CNTs are highly sensitive to strain, pressure, humidity, and gas molecules, enabling a wide range of printed sensor types:

-

Strain and pressure sensors for robotics or medical wearables

-

Chemical and gas sensors (e.g., ammonia, CO₂)

-

Bioelectronic interfaces for physiological monitoring

The printed CNT network acts both as the sensing element and as the conductive pathway, simplifying design.

6.3 Transparent Conductive Films

CNT-based coatings are increasingly used as ITO alternatives in touchscreens, displays, and solar cells.

They offer:

-

Excellent flexibility and durability

-

Stable performance under bending and temperature cycling

-

Good optical transparency

When blended with silver nanowires or graphene, hybrid films achieve enhanced conductivity and transparency.

6.4 Printed Heaters

Because of their high Joule heating efficiency, CNT inks can form lightweight, flexible heating layers:

-

For de-icing systems, smart clothing, and mirror heaters

-

Compatible with DC or low-voltage power

-

Offer uniform temperature distribution and fast response

CNT heaters are especially valuable where metal oxidation or brittleness is a concern.

6.5 Energy Storage and Conversion

CNT conductive coatings improve electron transport in:

-

Battery current collectors

-

Supercapacitor electrodes

-

Printed energy harvesting circuits

Their porous structure and high conductivity enhance both charge mobility and mechanical adhesion, improving cycle stability.

7. Formulation and Processing Challenges

Despite strong potential, CNT conductive inks and pastes face some technical challenges that affect scalability and consistency.

7.1 Dispersion Stability

CNTs naturally form bundles due to van der Waals attraction. Achieving uniform dispersion without damaging nanotube structure is critical.

Approaches include:

-

Ultrasonic processing with dispersants

-

Functionalization (e.g., carboxyl or amine groups)

-

Surfactant-assisted stabilization

7.2 Contact Resistance

Electrical conductivity depends on inter-tube contact. Optimizing CNT aspect ratio, concentration, and curing conditions helps achieve continuous percolation networks.

7.3 Substrate Adhesion

Different substrate materials (PET, PI, paper, etc.) require specific surface treatments or primers for stable adhesion and conductivity.

7.4 Process Optimization

For industrial roll-to-roll printing, parameters such as viscosity, drying rate, and curing temperature must be precisely controlled to maintain performance consistency.

8. Environmental and Durability Advantages

One of the major advantages of CNT-based conductive materials is their environmental stability:

-

Resistant to oxidation, corrosion, and UV aging

-

Maintain conductivity in humid or outdoor conditions

-

Do not rely on precious metals or toxic components

Additionally, water-based CNT inks are now available, offering low-VOC, eco-friendly, and safe alternatives to solvent-based systems.

9. Future Development Trends

The CNT ink and paste industry is evolving rapidly, driven by printed electronics, wearable devices, and IoT integration.

Emerging directions include:

9.1 Hybrid Nanomaterial Formulations

Combining CNTs with graphene flakes, silver nanowires, or conductive polymers to balance conductivity and processability.

9.2 Stretchable Electronics

Developing elastomer-compatible CNT inks that maintain conductivity even under 50–100% strain, suitable for e-skin and biomedical wearables.

9.3 Transparent EMI Shielding

CNT coatings are being used for electromagnetic interference (EMI) control in transparent devices, drones, and 5G equipment.

9.4 Low-Temperature Processing

Formulations optimized for plastic substrates and textiles, enabling direct printing on flexible surfaces without thermal damage.

CNT conductive pastes and inks are redefining the materials landscape for printed and flexible electronics.

With their combination of high conductivity, mechanical flexibility, and environmental durability, they offer a practical and scalable alternative to traditional metal-based inks.

As production processes mature and dispersion technologies improve, CNT-based formulations will continue to expand into sensors, transparent conductors, flexible circuits, and energy systems, bridging the gap between nanomaterials research and industrial manufacturing.

For manufacturers and integrators in the printed electronics field, understanding CNT ink composition, process control, and application compatibility will be key to achieving reliable and commercially viable products.