CNT Electrodes for Fuel Cells – Enhancing Performance and Durability

1. Introduction: The Role of Electrodes in Fuel Cells

Fuel cells are gaining increasing attention as clean and efficient energy conversion devices, particularly in applications such as hydrogen-powered vehicles, stationary power systems, and backup energy solutions. Their performance, efficiency, and lifetime are strongly influenced by the electrode materials used in the electrochemical reactions.

Traditional fuel cell electrodes are typically based on carbon black–supported noble metal catalysts. While widely adopted, these materials face challenges including limited durability, poor catalyst utilization, corrosion under harsh operating conditions, and performance degradation over time.

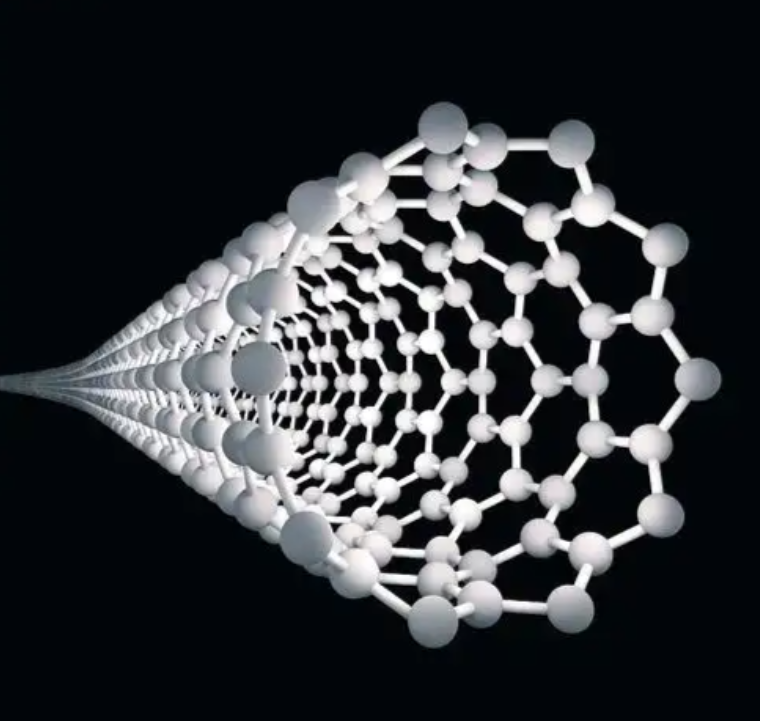

Carbon nanotubes (CNTs), with their unique one-dimensional structure, high electrical conductivity, and exceptional mechanical strength, are increasingly explored as advanced electrode materials or catalyst supports for next-generation fuel cells.

2. Fundamentals of Fuel Cell Electrodes

In proton exchange membrane fuel cells (PEMFCs) and other fuel cell types, electrodes must simultaneously provide:

-

High electrical conductivity

-

Efficient gas diffusion pathways

-

Large electrochemically active surface area

-

Strong catalyst anchoring

-

Chemical and electrochemical stability

The electrode structure must enable rapid electron transport, effective mass transfer of reactants (H₂, O₂), and long-term operation under acidic, humid, and high-potential environments.

3. Why Carbon Nanotubes Are Attractive for Fuel Cell Electrodes

CNTs offer several key advantages over conventional carbon black materials.

3.1 Superior Electrical Conductivity

CNTs form continuous, highly conductive networks that reduce internal resistance and improve current collection within the electrode layer.

3.2 High Aspect Ratio and Percolation Efficiency

Due to their one-dimensional structure, CNTs achieve electrical percolation at much lower loadings than carbon black, allowing:

-

Thinner electrode layers

-

Improved gas diffusion

-

Reduced mass transport losses

3.3 Enhanced Catalyst Utilization

CNT surfaces enable more uniform dispersion of Pt and other catalysts, increasing the electrochemically active surface area (ECSA) and reducing precious metal loading.

3.4 Mechanical and Structural Stability

CNT-based electrodes exhibit greater resistance to:

-

Mechanical stress

-

Catalyst detachment

-

Carbon corrosion during start–stop cycling

This directly contributes to extended fuel cell lifetime.

4. Types of CNTs Used in Fuel Cell Electrodes

4.1 Multi-Walled Carbon Nanotubes (MWCNTs)

-

More cost-effective

-

High durability

-

Widely used in commercial-scale research

MWCNTs are commonly employed as catalyst supports and conductive networks.

4.2 Single-Walled Carbon Nanotubes (SWCNTs)

-

Higher intrinsic conductivity

-

Larger specific surface area

-

Higher cost and processing complexity

Used mainly in high-performance or low-loading catalyst systems.

4.3 Functionalized CNTs

Surface functionalization (e.g., –COOH, –OH, N-doping) improves:

-

Catalyst anchoring

-

Electrode wettability

-

Interaction with ionomers

However, excessive functionalization can reduce electrical conductivity, requiring careful optimization.

5. Electrode Design Considerations

5.1 CNT Dispersion and Network Formation

Achieving uniform CNT dispersion is critical. Poor dispersion leads to:

-

Agglomeration

-

Uneven catalyst distribution

-

Increased mass transport resistance

Common dispersion methods include ultrasonic treatment, surfactant-assisted mixing, and in situ catalyst growth.

5.2 Catalyst Deposition Strategies

Catalysts can be introduced via:

-

Chemical reduction

-

Atomic layer deposition (ALD)

-

Electrochemical deposition

CNTs provide stable anchoring sites that help maintain catalyst activity under cycling conditions.

5.3 Ionomer Integration

The balance between CNTs and ionomers (e.g., Nafion) is essential:

-

Too little ionomer limits proton transport

-

Too much blocks gas diffusion

CNT networks help maintain conductive pathways even at lower ionomer content.

5.4 Durability and Corrosion Resistance

CNTs show improved resistance to carbon corrosion compared with carbon black, especially under high-potential conditions during fuel cell startup and shutdown.

6. Performance Benefits in Fuel Cells

CNT-based electrodes have demonstrated:

-

Higher power density

-

Lower catalyst loading requirements

-

Improved start–stop durability

-

Enhanced performance at low humidity

These advantages are particularly valuable for automotive PEM fuel cells, where both efficiency and lifetime are critical.

7. Manufacturing and Scale-Up Challenges

Despite their advantages, CNT electrodes face challenges in commercialization:

-

Cost and supply consistency

-

Large-scale dispersion control

-

Integration into existing electrode fabrication lines

-

Health and safety considerations during handling

Hybrid systems combining CNTs with carbon black are often used to balance cost and performance.

8. Future Outlook

CNT electrodes are expected to play an increasing role as fuel cell technology moves toward:

-

Lower platinum loadings

-

Higher durability targets

-

More aggressive operating conditions

Emerging trends include:

-

CNT-supported non-precious metal catalysts

-

3D CNT networks for improved mass transport

-

Integration with advanced membrane and catalyst layer designs

As hydrogen infrastructure expands, CNT-based electrode materials are poised to become a key enabler of cost-effective, durable fuel cell systems.

Carbon nanotubes offer a compelling pathway to enhance fuel cell electrode performance and durability. Their high conductivity, structural robustness, and catalyst-support capabilities address many of the limitations of traditional carbon black electrodes.

With continued advances in CNT production, dispersion technology, and electrode engineering, CNT-based electrodes are expected to move from advanced research into broader commercial adoption across fuel cell applications.