CNT-Reinforced Thermoplastics – Melt Compounding Strategies

1. Why Melt Compounding Matters

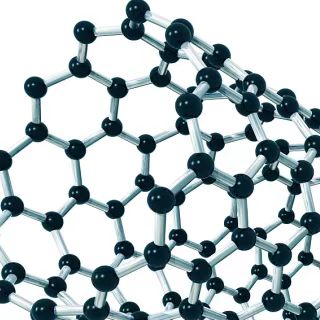

Carbon nanotubes (CNTs) are widely recognized for their exceptional electrical and mechanical properties. However, for industrial adoption, how CNTs are incorporated into thermoplastics is often more critical than the CNT properties themselves.

Among various processing routes, melt compounding remains the most scalable and industry-compatible approach, aligning with existing extrusion, injection molding, and filament production lines.

2. Challenges of CNT Incorporation in Thermoplastics

Despite their advantages, CNTs introduce several challenges during melt processing:

-

Strong agglomeration tendency

-

High melt viscosity increase

-

Sensitivity to shear and thermal history

-

Dispersion–property trade-offs

Effective melt compounding strategies are essential to achieve consistent performance at industrial scale.

3. Why CNTs Are Effective Reinforcements in Thermoplastics

CNTs offer:

-

High aspect ratio for network formation

-

Low percolation threshold for conductivity

-

Mechanical reinforcement at low loading

-

Multi-functionality (conductive + structural)

These benefits can be realized only if CNT dispersion and interfacial interaction are properly controlled.

4. Melt Compounding as an Industrial Processing Route

Melt compounding involves:

-

Feeding CNTs and polymer pellets into an extruder

-

Applying controlled heat and shear

-

Dispersing CNTs within the molten polymer

Compared with solution-based processing, melt compounding avoids solvents and supports continuous, high-throughput production.

5. CNT Dispersion Mechanisms During Melt Mixing

Dispersion during melt compounding occurs through:

-

Agglomerate breakup under shear

-

Distribution of CNTs throughout the matrix

-

Network formation at or above percolation threshold

However, excessive shear may damage CNT structure, reducing effective aspect ratio.

6. Key Melt Compounding Strategies

6.1 Masterbatch Approach

CNTs are first compounded at high concentration into a masterbatch, which is later diluted.

Advantages:

-

Improved handling and safety

-

Better dispersion control

-

Process flexibility

Consideration:

Masterbatch dilution must preserve CNT network continuity.

6.2 Direct Feeding Approach

CNTs are fed directly into the melt stream.

Advantages:

-

Fewer processing steps

-

Potential cost reduction

Challenges:

-

Dust handling

-

Higher risk of agglomeration

Direct feeding requires precise feeder control and screw design.

7. Screw Design and Shear Management

Extruder screw configuration strongly influences CNT dispersion:

-

High-shear zones for agglomerate breakup

-

Mixing elements for distribution

-

Low-shear zones to preserve CNT length

Balanced shear is key to achieving good dispersion without CNT damage.

8. Processing Temperature and Residence Time

-

Temperatures must exceed polymer melting point but avoid degradation

-

Longer residence time improves dispersion but increases thermal stress

Optimizing the thermal–shear window is critical for stable processing.

9. Polymer Matrix Considerations

CNT reinforcement behavior varies by polymer type:

| Polymer | Processing Notes |

|---|---|

| PP / PE | Low polarity, dispersion more challenging |

| ABS | Good balance of processability and adhesion |

| Nylon (PA) | Strong interfacial interaction, moisture control required |

| PC | High temperature stability, viscosity management important |

Matrix selection affects dispersion efficiency and final properties.

10. Property Optimization Trade-Offs

Increasing CNT loading improves conductivity and stiffness but may:

-

Increase melt viscosity

-

Reduce elongation at break

-

Complicate molding processes

Material design should target application-driven performance, not maximum CNT content.

11. Quality Control and Reproducibility

Industrial-scale production requires:

-

Batch-to-batch consistency

-

Controlled CNT morphology

-

Stable dispersion metrics

Rheology, electrical resistivity, and microscopy are commonly used quality indicators.

12. Applications of CNT-Reinforced Thermoplastics

-

EMI shielding housings

-

Antistatic and ESD components

-

Structural electronic parts

-

Conductive 3D printing filaments

-

Lightweight automotive components

13. Future Directions

-

Hybrid CNT–graphene reinforcement

-

Lower-shear dispersion technologies

-

Process-integrated functionalization

-

Application-specific CNT grades

CNT-reinforced thermoplastics produced via melt compounding offer a scalable pathway to multifunctional materials.

Success depends on:

-

Dispersion strategy

-

Shear and temperature control

-

Polymer compatibility

-

Performance–processability balance

Rather than maximizing CNT content, effective material design focuses on controlled network formation within manufacturable processing windows.