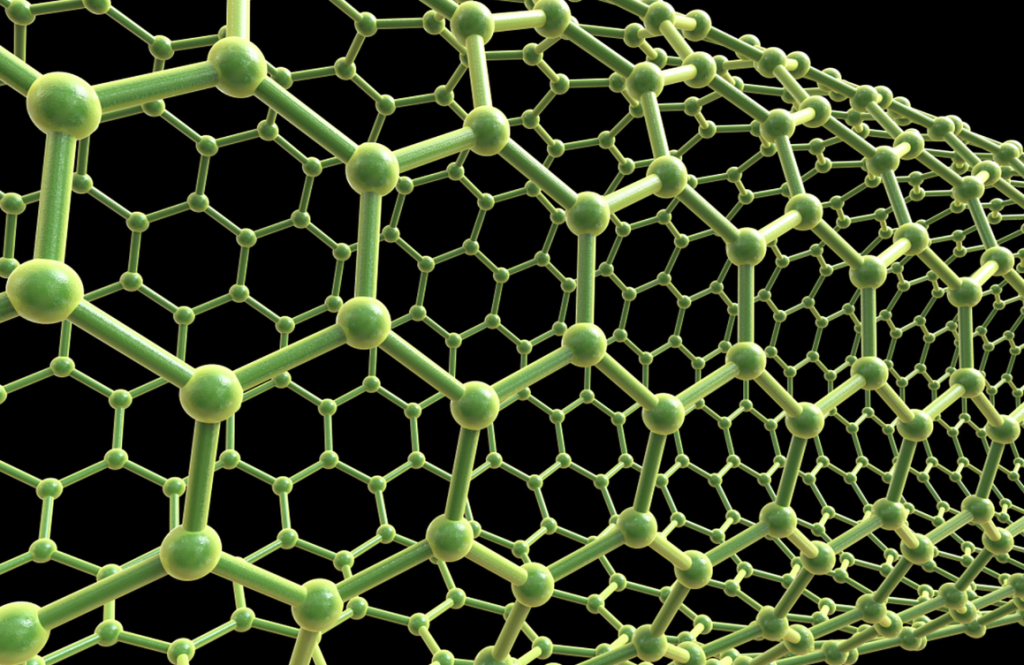

CNT Support for Non-Precious Metal Catalysts

1. Introduction: Reducing Catalyst Cost in Fuel Cells

One of the major barriers to the large-scale commercialization of fuel cell technology is the reliance on precious metal catalysts, particularly platinum. Although platinum offers excellent catalytic activity, its high cost, limited availability, and price volatility significantly increase system costs.

Non-precious metal catalysts (NPMCs), such as iron–nitrogen–carbon (Fe–N–C), cobalt-based, and metal–nitrogen coordinated catalysts, are actively researched as alternatives. However, their performance and durability are highly dependent on the support material used.

Carbon nanotubes (CNTs) have emerged as a highly effective support for NPMCs, offering improved electrical conductivity, structural stability, and catalyst utilization compared to traditional carbon supports.

2. Role of Catalyst Supports in Fuel Cells

Catalyst supports serve multiple critical functions:

-

Provide electrically conductive pathways

-

Anchor active catalytic sites

-

Enable reactant and product transport

-

Maintain structural integrity under operating conditions

For NPMCs, which often have lower intrinsic conductivity and stability than platinum catalysts, the choice of support becomes even more critical.

3. Challenges of Non-Precious Metal Catalysts

Despite rapid progress, NPMCs face several inherent challenges:

-

Lower conductivity compared to Pt-based catalysts

-

Susceptibility to degradation under acidic and oxidative conditions

-

Limited active site density accessibility

-

Performance loss at high current densities

These limitations make advanced support materials essential for enabling practical fuel cell performance.

4. Why CNTs Are Ideal Supports for NPMCs

4.1 High Electrical Conductivity

CNTs provide continuous electron transport pathways, compensating for the lower conductivity of many NPMCs and reducing electrode resistance.

4.2 One-Dimensional Network Structure

The fibrous CNT network:

-

Enhances percolation at low loadings

-

Reduces contact resistance

-

Maintains conductivity under cycling

This is particularly beneficial for NPMC systems with dispersed active sites.

4.3 Enhanced Catalyst Anchoring

CNT surfaces enable strong interaction with metal–nitrogen active sites, improving:

-

Catalyst dispersion

-

Resistance to agglomeration

-

Retention of active sites during operation

4.4 Improved Mass Transport

CNT-based structures form interconnected pores that facilitate:

-

Oxygen diffusion

-

Water management

-

Reaction product removal

This supports higher current density operation.

5. CNT Functionalization and Active Site Formation

5.1 Surface Functionalization

Functional groups such as –COOH, –OH, and nitrogen doping improve:

-

Metal coordination

-

Wettability

-

Catalyst–support interaction

However, excessive functionalization may reduce conductivity, requiring careful optimization.

5.2 Nitrogen-Doped CNTs

Nitrogen doping creates:

-

Defect sites for metal coordination

-

Enhanced catalytic activity

-

Improved ORR (oxygen reduction reaction) performance

N-doped CNTs are widely used in Fe–N–C catalyst systems.

6. Performance Advantages in Fuel Cells

CNT-supported NPMCs have demonstrated:

-

Higher ORR activity compared to carbon black–supported systems

-

Improved power density at medium-to-high current densities

-

Enhanced durability during start–stop cycling

-

Reduced performance decay under acidic conditions

These improvements bring NPMCs closer to meeting commercial PEMFC targets.

7. Comparison with Carbon Black Supports

Compared to carbon black, CNT supports offer:

-

Superior conductivity at lower loadings

-

Better resistance to carbon corrosion

-

Improved catalyst site accessibility

-

More stable electrode structures

Carbon black remains cost-effective, but CNTs enable higher-performance, longer-life NPMC systems.

8. Manufacturing and Scalability Considerations

Key challenges include:

-

Consistent CNT quality and purity

-

Scalable catalyst deposition methods

-

Control of CNT dispersion at high solids loading

Hybrid supports combining CNTs with carbon black are commonly used to balance cost and performance.

9. Future Outlook

CNT-supported NPMCs are expected to play a crucial role in:

-

Ultra-low or zero-platinum fuel cells

-

Heavy-duty and automotive PEMFCs

-

Cost-sensitive stationary power systems

Ongoing research focuses on:

-

Increasing active site density

-

Enhancing long-term stability

-

Optimizing CNT functionalization strategies

Carbon nanotubes provide a powerful support platform for non-precious metal catalysts in fuel cells. By enhancing conductivity, stabilizing active sites, and improving mass transport, CNTs address many of the fundamental limitations that have historically constrained NPMC performance.

As the fuel cell industry moves toward cost reduction and scalability, CNT-supported NPMCs represent a critical pathway toward platinum-free fuel cell technologies.