CNT vs Carbon Black in Fuel Cell Electrodes

1. Why Electrode Carbon Matters

In proton exchange membrane fuel cells (PEMFCs) and other low-temperature fuel cell systems, carbon materials play a critical role as catalyst supports and conductive networks. While noble metal catalysts drive electrochemical reactions, it is the carbon matrix that determines electron transport, catalyst utilization, mass transfer efficiency, and long-term durability.

Carbon black has been the industry standard for decades due to its low cost and established processing routes. However, as fuel cell targets shift toward higher power density, lower platinum loading, and longer lifetime, the limitations of carbon black are becoming increasingly apparent.

Carbon nanotubes (CNTs) are now widely investigated as an alternative or complementary carbon material, offering distinct structural and electrical advantages. This article provides a direct technical comparison between CNTs and carbon black in fuel cell electrodes, focusing on performance, durability, processing, and cost considerations.

2. Structural Differences and Their Impact

2.1 Carbon Black: Zero-Dimensional Aggregates

Carbon black consists of quasi-spherical primary particles (typically 20–50 nm) that form branched aggregates. While this structure provides a high surface area, it relies heavily on particle–particle contact for electrical conduction.

Under mechanical stress or electrochemical corrosion, these contacts degrade, increasing resistance over time.

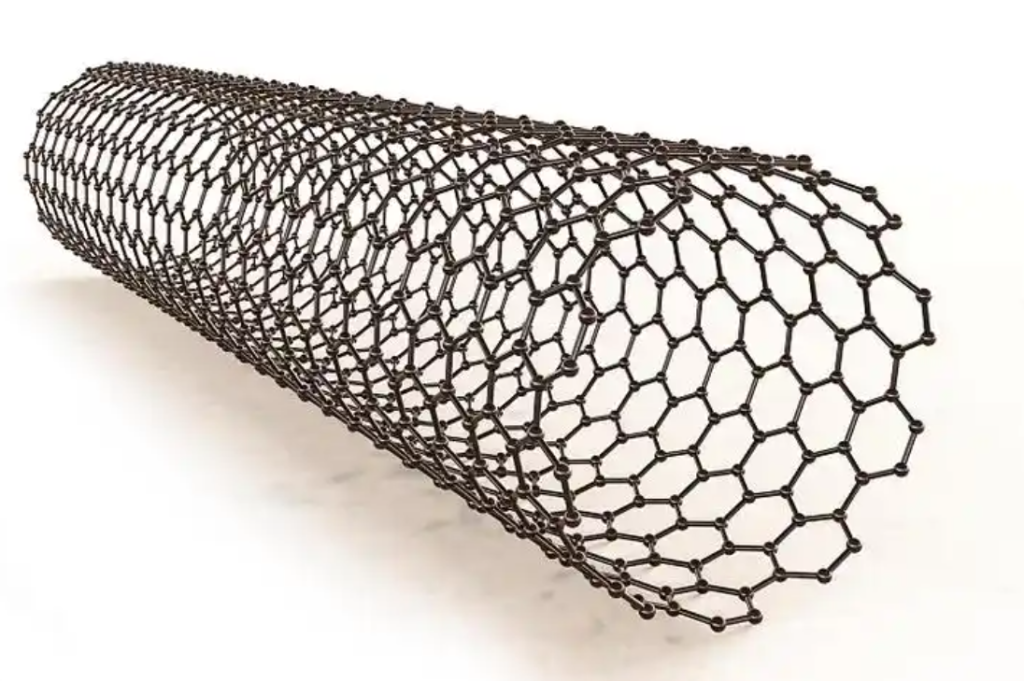

2.2 CNTs: One-Dimensional Conductive Networks

CNTs possess a high aspect ratio, forming continuous, interconnected conductive pathways throughout the electrode. This structure enables:

-

Efficient electron transport

-

Lower percolation thresholds

-

Reduced dependence on particle contacts

As a result, CNT-based electrodes maintain conductivity more effectively during long-term operation.

3. Electrical Conductivity and Catalyst Utilization

3.1 Conductive Pathways

Carbon black requires relatively high loading to achieve sufficient conductivity, which can:

-

Increase electrode thickness

-

Limit gas diffusion

-

Reduce catalyst accessibility

CNTs achieve comparable or superior conductivity at much lower loadings, allowing for thinner, more efficient electrode layers.

3.2 Catalyst Dispersion and ECSA

CNT surfaces enable more uniform platinum dispersion, improving the electrochemically active surface area (ECSA). Carbon black, while offering high surface area, often suffers from:

-

Catalyst agglomeration

-

Poor utilization efficiency

Improved catalyst utilization directly supports platinum reduction strategies, a key industry objective.

4. Mass Transport and Water Management

Efficient fuel cell operation depends on balanced gas diffusion and water removal.

-

Carbon Black Electrodes: Dense structures can restrict gas transport and exacerbate flooding under high current densities.

-

CNT-Based Electrodes: Open, fibrous networks create interconnected pores that improve oxygen diffusion and water management.

This advantage becomes increasingly important in automotive PEMFCs operating under dynamic load conditions.

5. Durability and Carbon Corrosion Resistance

5.1 Start–Stop and High-Potential Degradation

Fuel cell electrodes experience high potentials during start–stop cycles, accelerating carbon corrosion.

Carbon black is prone to:

-

Oxidation

-

Structural collapse

-

Catalyst detachment

CNTs exhibit improved resistance to electrochemical oxidation, helping preserve electrode integrity and catalyst anchoring.

5.2 Mechanical Stability

CNT-based electrodes show higher resistance to:

-

Compression

-

Thermal cycling

-

Catalyst layer cracking

This translates into longer operational lifetimes, especially in demanding duty cycles.

6. Processing and Manufacturing Considerations

6.1 Dispersion and Ink Formulation

Carbon black benefits from decades of optimization and is relatively easy to disperse in catalyst inks.

CNTs require:

-

More sophisticated dispersion techniques

-

Control of agglomeration

-

Optimized binder and ionomer systems

However, once properly dispersed, CNT inks provide more stable conductive networks.

6.2 Compatibility with Existing Production Lines

Carbon black remains attractive due to:

-

Established supply chains

-

Low raw material cost

-

Compatibility with current electrode manufacturing

CNTs are increasingly used in hybrid formulations, combining CNTs with carbon black to balance cost, performance, and processability.

7. Cost–Performance Trade-Off

| Parameter | Carbon Black | CNTs |

|---|---|---|

| Raw material cost | Low | Higher |

| Conductivity per loading | Moderate | High |

| Catalyst utilization | Moderate | High |

| Durability | Limited | Superior |

| Pt reduction potential | Limited | Strong |

While CNTs are more expensive on a per-kilogram basis, their ability to:

-

Reduce platinum loading

-

Extend electrode lifetime

-

Improve power density

often results in lower total system cost over the fuel cell’s lifespan.

8. Hybrid Carbon Architectures: The Best of Both Worlds

Many commercial and pre-commercial designs adopt CNT–carbon black hybrid electrodes, where:

-

Carbon black provides surface area and cost efficiency

-

CNTs form a reinforcing conductive network

This approach minimizes CNT usage while capturing most of their performance benefits.

9. Application-Specific Selection Guide

-

Automotive PEMFCs: CNT or CNT-hybrid systems for durability and power density

-

Stationary Fuel Cells: Carbon black remains viable where cost dominates

-

Low-Pt or Pt-Free Catalysts: CNTs strongly preferred

-

High-Current Density Designs: CNT-based electrodes outperform

10. Conclusion

Carbon black remains a practical and cost-effective electrode material for fuel cells, particularly in mature and cost-sensitive systems. However, as performance targets rise and durability requirements tighten, its limitations become increasingly restrictive.

Carbon nanotubes offer a compelling alternative by enabling superior conductivity, catalyst utilization, mass transport, and long-term stability. In many advanced fuel cell designs, CNTs—either alone or in hybrid architectures—are emerging as the preferred choice.

For developers seeking to push fuel cell technology toward higher efficiency and longer lifetime, CNT-based electrode materials represent a strategic upgrade rather than a simple material substitution.