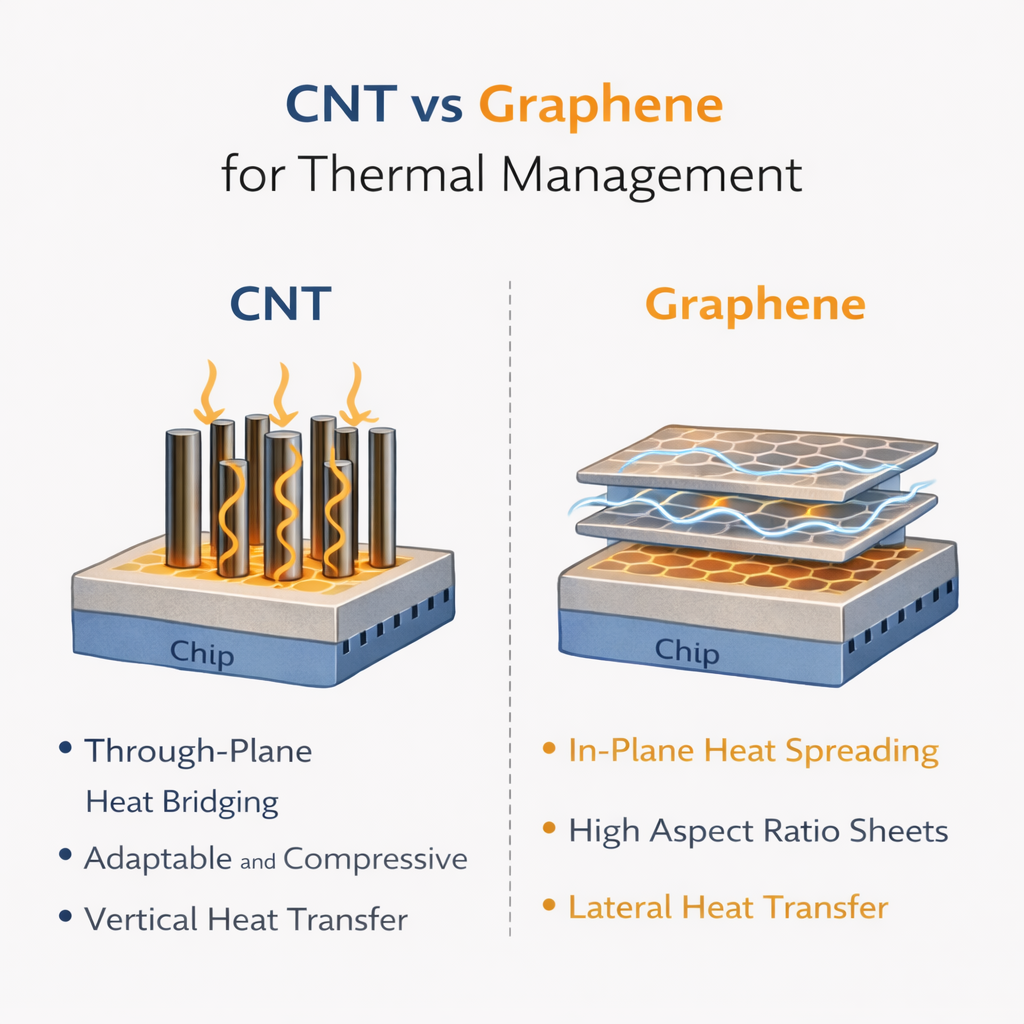

CNT vs Graphene for Thermal Management

Strengths, Limitations, and Application-Driven Choices

Carbon nanotubes (CNTs) and graphene are two of the most widely discussed nanocarbon materials for thermal management. Both offer exceptional intrinsic thermal conductivity, yet their real-world performance differs significantly once they are integrated into coatings, thermal interface materials (TIMs), or composite systems.

Understanding where each material excels—and where it falls short—is critical for making the right engineering choice.

This article compares CNTs and graphene from a practical thermal-engineering perspective, focusing on performance, processing, and application suitability.

1. Intrinsic Thermal Properties: Numbers vs Reality

| Material | Intrinsic Thermal Conductivity (Ideal) |

|---|---|

| Graphene (in-plane) | ~2000–5000 W/m·K |

| CNT (axial direction) | ~3000 W/m·K |

On paper, both materials appear outstanding.

In practice, however, intrinsic values rarely translate directly into system-level performance.

Why?

Because thermal management is not just about bulk conductivity—it is about:

-

Phonon transport continuity

-

Contact resistance

-

Network formation

-

Interface conformity

This is where CNTs and graphene begin to diverge.

2. Graphene: Strengths and Limitations

Key Strengths of Graphene

① Exceptional In-Plane Heat Spreading

Graphene’s 2D sheet structure enables extremely efficient lateral heat dissipation, making it ideal for:

-

Heat spreader coatings

-

EMI + thermal multifunctional layers

-

Large-area thermal films

② Barrier and Stability Benefits

Graphene layers can also provide:

-

Chemical resistance

-

Gas and moisture barrier properties

-

Improved coating durability

③ High Aspect Ratio (Lateral)

When aligned or well-dispersed, graphene forms conductive planes that efficiently redistribute heat across surfaces.

Limitations of Graphene in Thermal Interfaces

① Poor Through-Plane Conductivity

Heat transfer perpendicular to graphene sheets is significantly lower due to:

-

Weak interlayer coupling

-

Phonon scattering at sheet interfaces

② Interface Contact Challenges

Graphene sheets:

-

Do not naturally conform to surface roughness

-

Tend to restack or agglomerate

-

Create air gaps at real interfaces

③ Performance Highly Depends on Orientation

Without controlled alignment, much of graphene’s intrinsic advantage is lost in practical assemblies.

3. CNTs: Strengths and Limitations

Key Strengths of CNTs

① Excellent Through-Thickness Heat Pathways

CNTs form 1D conductive bridges, allowing heat to move efficiently:

-

Across interfaces

-

Between uneven or rough surfaces

This makes CNTs particularly effective in:

-

Thermal interface materials (TIMs)

-

Gap fillers

-

Vertically conductive composites

② High Compliance and Conformability

CNT networks can:

-

Compress under low pressure

-

Adapt to surface irregularities

-

Reduce thermal contact resistance (TCR)

③ Robust Percolation Networks

Even at relatively low loadings, CNTs can form continuous heat-conducting pathways.

Limitations of CNTs

① Lower In-Plane Heat Spreading

Compared to graphene sheets, CNTs are less effective at lateral heat distribution.

② Dispersion and Cost Challenges

-

CNT dispersion requires careful processing

-

High-purity CNTs can be cost-intensive

-

Agglomeration affects consistency if not controlled

③ Limited Barrier or Structural Effects

CNTs provide less benefit in terms of corrosion resistance or barrier properties compared to graphene.

4. CNT vs Graphene: Application-Oriented Comparison

| Application | Better Choice | Reason |

|---|---|---|

| Thermal Interface Materials (TIMs) | CNT | Lower contact resistance, vertical pathways |

| Gap fillers / compressible pads | CNT | Compliance and surface conformity |

| Heat spreader coatings | Graphene | Superior in-plane conductivity |

| EMI + thermal coatings | Graphene | Sheet structure + conductivity |

| Thin interfaces (<100 μm) | CNT–Graphene hybrid | Balanced conduction + interface control |

| Battery modules | Hybrid | Interface + spreading both matter |

5. Why Hybrid CNT–Graphene Systems Are Emerging

In real assemblies, no single material solves all thermal challenges.

Hybrid CNT–graphene systems combine:

-

CNTs for vertical heat transfer and interface bridging

-

Graphene for lateral heat spreading and structural reinforcement

This synergy:

-

Reduces thermal contact resistance

-

Improves thickness efficiency

-

Enhances long-term reliability under cycling

As power densities increase in batteries, inverters, and power electronics, hybrid architectures are becoming the engineering default rather than the exception.

6. Engineering Takeaway

Graphene spreads heat. CNTs connect heat.

Thermal performance depends more on interfaces than on intrinsic conductivity alone.

Selecting CNTs, graphene, or a hybrid system should be driven by:

-

Heat flow direction

-

Interface roughness

-

Mechanical constraints

-

Reliability requirements

Understanding these trade-offs enables smarter thermal design—and avoids costly overengineering.