CNTs in Flexible Circuit Boards: Building the Future of Electronics

The electronics industry is rapidly shifting toward lightweight, flexible, and high-performance devices. Traditional rigid circuit boards are no longer sufficient to meet the needs of emerging technologies such as wearable electronics, foldable displays, medical sensors, and the Internet of Things (IoT).

Flexible circuit boards (FPCBs) have become an essential technology for next-generation devices. However, most FPCBs still rely on copper or silver conductive lines. While these metals provide excellent conductivity, they suffer from poor flexibility, high weight, cracking under repeated bending, and elevated production costs.

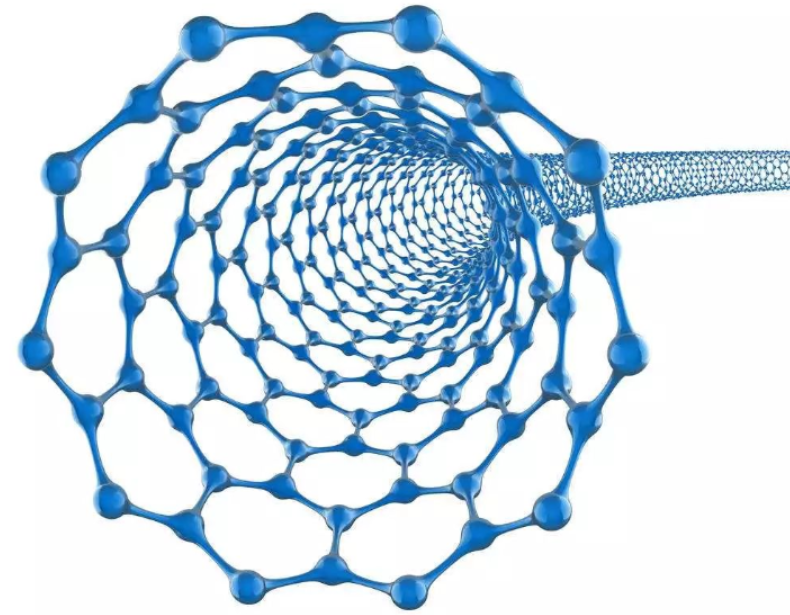

Carbon nanotubes (CNTs), with their extraordinary electrical conductivity, outstanding flexibility, lightweight nature, and superior durability, are emerging as an ideal solution for the future of flexible electronics. By integrating CNTs into flexible circuits, engineers can achieve high-performance, durable, and scalable circuits that will drive the next wave of innovation in consumer and industrial electronics.

Why CNTs for Flexible Circuit Boards?

Flexible circuits demand materials that combine electrical conductivity, mechanical flexibility, durability, and cost-effectiveness. Metals like copper often fail under extreme bending or repeated use. CNTs offer a unique balance of properties:

-

High Conductivity – CNT networks exhibit conductivity comparable to copper while being much lighter.

-

Flexibility and Durability – CNTs can maintain performance even under extreme bending or twisting.

-

Lightweight – Ideal for portable and wearable electronics.

-

Thermal Stability – Withstand high temperatures during both fabrication and operation.

-

Printable – CNTs can be processed into conductive inks for large-area printed electronics.

-

Fatigue Resistance – CNT circuits can survive tens of thousands of bending cycles without failure.

These attributes make CNTs highly suitable for flexible printed circuit boards (FPCBs) in advanced electronics.

Mechanisms of CNT Integration in Flexible Circuits

There are several ways CNTs can be incorporated into flexible circuits:

1. CNT Thin Films

-

Deposited on flexible substrates (polyimide, PET) using spray-coating, spin-coating, or chemical vapor deposition (CVD).

-

Create uniform conductive films to replace traditional metal traces.

2. CNT Conductive Inks

-

CNT dispersions are formulated into inks for inkjet or screen printing.

-

Enable low-cost, scalable, and high-resolution printed circuits.

3. CNT-Polymer Composites

-

CNTs embedded in polymers provide both mechanical flexibility and electrical pathways.

-

Useful for wearable electronics and medical patches.

4. Hybrid CNT Structures

-

CNTs combined with silver nanowires, graphene, or conductive polymers to improve conductivity while maintaining flexibility.

-

Balance cost and performance.

Applications of CNTs in Flexible Circuit Boards

1. Wearable Electronics

-

CNT-based FPCBs can be integrated into smartwatches, fitness trackers, and electronic textiles.

-

Maintain reliable conductivity even during stretching and bending.

-

Enable biosensors, motion trackers, and health monitoring patches.

2. Flexible Displays and Touch Panels

-

CNT transparent conductive films can replace ITO (indium tin oxide), which is brittle and expensive.

-

Support foldable smartphones, flexible tablets, and e-paper devices.

3. Medical Devices and Biosensors

-

CNT-FPCBs conform to the human body or can be implanted.

-

Enable applications such as ECG monitoring, neural interfaces, and wearable diagnostic patches.

4. Internet of Things (IoT) Devices

-

CNT circuits support flexible wireless modules and energy-harvesting systems.

-

Ideal for smart home devices, logistics sensors, and environmental monitoring.

5. Aerospace and Automotive Applications

-

Lightweight CNT-FPCBs reduce system weight while maintaining durability.

-

Useful in flexible sensor arrays, lightweight control electronics, and harsh-environment monitoring.

Case Studies and Research Highlights

-

Rice University: Developed CNT ink circuits that retain 95% conductivity after 10,000 bending cycles.

-

Samsung & LG: Investigating CNT transparent electrodes for foldable displays as a replacement for ITO.

-

MIT: Created CNT-polymer composites for flexible medical circuits that can adhere to skin for long-term health monitoring.

-

Japanese R&D Teams: Demonstrated CNT-based stretchable electronic textiles for smart clothing applications.

These breakthroughs highlight CNTs’ role in the next generation of flexible electronics.

Advantages of CNT-Based Flexible PCBs

-

Lightweight → Perfect for portable and wearable devices.

-

Bendability and Durability → Maintain function after tens of thousands of flex cycles.

-

High Conductivity → Comparable to metals but without brittleness.

-

Low-Cost Manufacturing → CNT conductive inks enable printed electronics at scale.

-

Scalable → Suitable for large-area circuit production.

-

Transparent and Flexible → Unlock new possibilities for foldable displays and see-through devices.

Market Potential

The global flexible circuit market is projected to surpass USD 6 billion by 2032, driven by wearables, flexible displays, and medical electronics.

The CNT market is expected to reach USD 3–4 billion by 2032, with electronics and conductive composites as primary growth areas.

CNT-based FPCBs represent a high-growth opportunity, particularly in:

-

ITO replacement for displays and touch panels.

-

Wearable healthcare electronics, driven by aging populations.

-

IoT and 5G electronics, requiring compact and flexible designs.

Challenges and Considerations

-

Dispersion and Processing – CNTs tend to agglomerate, which can reduce conductivity.

-

Cost – High-quality CNTs remain expensive.

-

Uniformity – Large-area circuits require consistent electrical performance.

-

Regulatory Standards – Medical and aerospace electronics demand strict certifications.

Future Outlook

In the next decade, CNTs in flexible PCBs will evolve in several directions:

-

Printed Electronics at Scale – Mass production of CNT inks for roll-to-roll manufacturing.

-

Transparent Flexible Circuits – Integration into foldable phones, AR/VR devices, and smart windows.

-

Stretchable Electronics – CNT circuits embedded in textiles and electronic skin.

-

Energy-Integrated Circuits – CNT FPCBs combined with CNT supercapacitors for self-powered devices.

-

Clinical Applications – CNT-based medical electronics entering real-world healthcare use.

As costs decline and processing techniques improve, CNTs are expected to become a mainstay material in flexible electronics, pushing the industry toward smarter, lighter, and more adaptable devices.

Carbon nanotubes (CNTs), with their exceptional combination of electrical conductivity, flexibility, and lightweight durability, are redefining the future of flexible printed circuit boards (FPCBs). Unlike traditional copper or silver lines, CNT circuits provide greater reliability under bending, scalability for printed electronics, and compatibility with wearable and transparent devices.

From wearables and flexible displays to medical sensors, IoT devices, and aerospace applications, CNT-based FPCBs are poised to play a critical role in shaping next-generation electronics. While challenges remain in cost, scalability, and reliability, ongoing innovations point to a future where CNT flexible circuits become the foundation of advanced, intelligent electronics systems.