CNTs in Lithium Battery Conductive Paste: The Invisible Enabler of Fast-Charging EVs

As the global electric vehicle (EV) market rapidly expands, driven by decarbonization goals and technological breakthroughs, the demand for high-performance lithium-ion batteries continues to soar. A critical yet often overlooked component in these advanced batteries is the conductive paste — particularly the type enhanced with carbon nanotubes (CNTs). In this article, we dive into the role of CNTs in conductive pastes and how they quietly but significantly enable fast-charging capabilities in EVs.

Understanding Conductive Paste in Lithium-Ion Batteries

Conductive paste, often referred to as conductive slurry, is used to form the electrode layers in lithium-ion batteries. Its main function is to provide an electronically conductive network that facilitates electron transport across the electrode structure. This paste is typically composed of active materials (e.g., NMC, LFP), binders (like PVDF), solvents (such as NMP or water), and conductive additives.

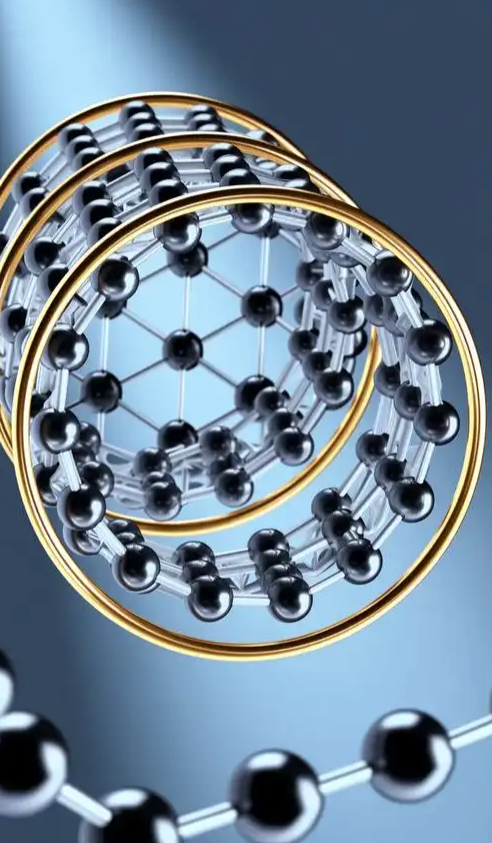

Traditionally, carbon black has been the standard conductive additive in these slurries. However, with increasing energy density requirements and the push for faster charging, carbon black is reaching its performance limitations. Enter carbon nanotubes (CNTs) — ultra-thin, highly conductive nanomaterials that redefine the boundaries of what conductive additives can achieve.

What Makes CNTs Special?

CNTs, particularly multi-walled (MWCNTs) and single-walled (SWCNTs) varieties, possess extraordinary properties:

-

High electrical conductivity: CNTs can conduct electricity more efficiently than carbon black, forming a percolative network at a lower dosage.

-

Mechanical strength and flexibility: This helps maintain structural integrity under stress.

-

Aspect ratio advantage: Their long, slender shape enables better connectivity between active material particles.

The result? Electrodes with improved electronic pathways, higher conductivity, and more robust mechanical integrity — all essential for high-rate discharge and fast-charging operations.

CNT-Enhanced Conductive Paste: Technical Advantages

When used in battery slurry, CNTs offer several distinct performance benefits:

1. Faster Charging Capability

CNTs reduce the internal resistance of the electrode, allowing for faster electron mobility during charge cycles. This translates into reduced charging times — a crucial metric for consumer satisfaction in EVs.

2. Lower Additive Loading

CNTs require only 0.1–0.5 wt% to achieve effective conductivity, compared to 2–3 wt% for carbon black. This lower loading frees up more space for active material, enhancing energy density.

3. Improved Cyclability and Stability

The enhanced mechanical strength of CNT networks results in less electrode degradation over repeated cycles, extending battery life.

4. Superior Low-Temperature Performance

At sub-zero temperatures, CNTs maintain conductivity better than carbon black, supporting the development of EVs suitable for cold-climate markets.

Real-World Applications in EV Batteries

Chinese battery giants like CATL and BYD have already adopted CNT-enhanced slurries in their high-rate cells. This has enabled:

-

4C–6C fast-charging capability (i.e., full charge in 10–15 minutes)

-

Improved performance in high-nickel chemistries like NMC811

-

Weight and volume reduction in cell design due to thinner, more efficient electrodes

These gains make CNTs a cornerstone of next-generation power battery platforms.

Challenges in CNT Slurry Formulation

Despite the advantages, working with CNTs isn’t without challenges:

-

Dispersion difficulties: CNTs tend to agglomerate due to van der Waals forces. Proper dispersion requires surfactants, high-shear mixing, or proprietary dispersing agents.

-

Cost considerations: CNTs are more expensive than carbon black, although large-scale production and domestic suppliers in China are driving prices down.

-

Process integration: Battery manufacturers need to optimize mixing processes and slurry rheology to fully harness CNT benefits.

To address these issues, companies like Ningbo GrapheneRich NanoTech have developed CNT dispersions and pre-formulated conductive pastes that offer stable, ready-to-use solutions for slurry manufacturers.

Outlook: CNTs as a Strategic Material in Battery Innovation

The use of CNTs in lithium battery conductive pastes represents more than a performance upgrade — it signals a shift toward material-level innovation in energy storage. As electric vehicles become faster, lighter, and more efficient, CNTs will play an increasingly vital role behind the scenes.

In China, the world’s largest EV and battery market, the industrial ecosystem for CNTs is maturing rapidly. With government backing, increasing R&D investment, and scalable production capacity, CNT adoption is expected to accelerate in both domestic and export-oriented battery platforms.

Key Takeaways

-

CNTs dramatically improve electrical conductivity and mechanical integrity in lithium-ion battery electrodes.

-

They enable fast-charging, better cycle life, and higher energy density compared to traditional carbon black.

-

Challenges such as dispersion and cost are being overcome with advanced formulations and local supply chains.

-

CNTs are becoming an essential component in high-performance EV batteries, especially in 4C–6C charge-rate designs.